Portable power source type track laying machine for subway construction

A technology of mobile power supply and laying machine, which is applied in the direction of track, track maintenance, track laying, etc. It can solve the problems that affect the construction progress, increase the cost of equipment use, and burn the motor rotor coil, so as to save labor and improve the passing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

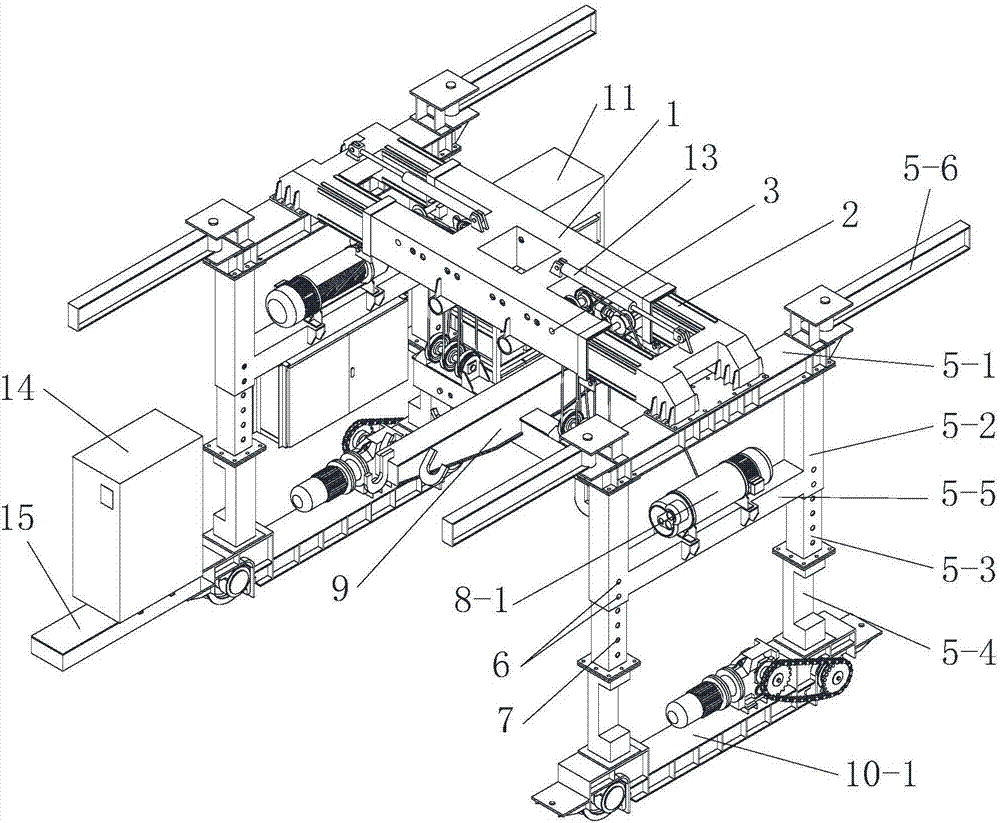

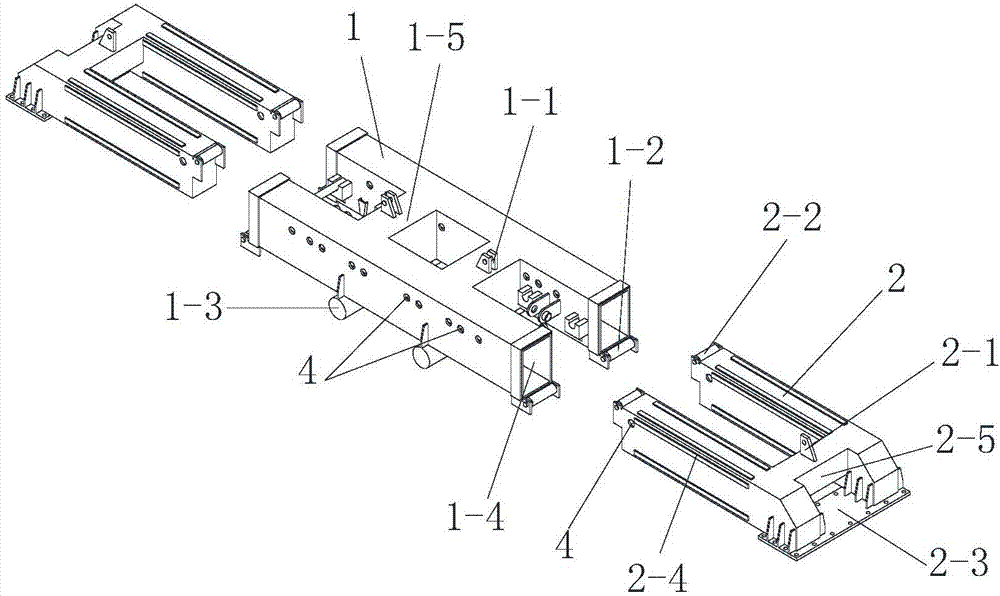

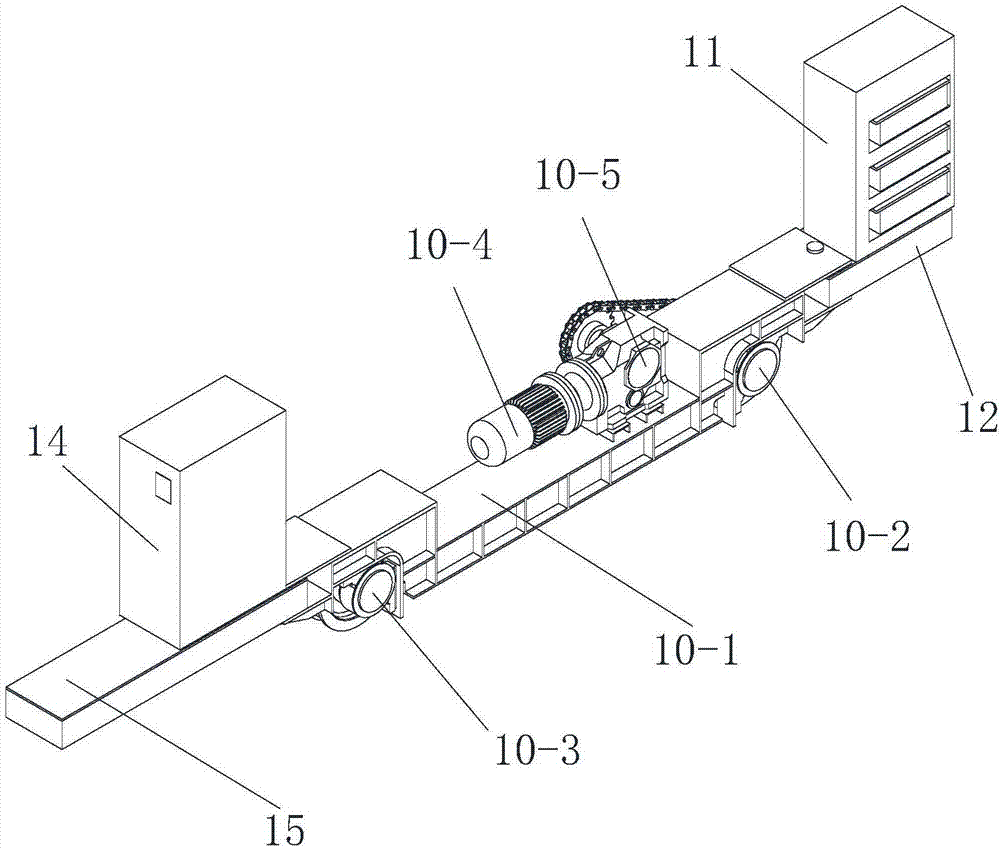

[0049] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a portal bracket, a lifting device installed on the portal bracket and a running device for driving the portal bracket to move back and forth, and also includes a lifting device installed on the portal bracket or the running device The mobile power supply 11, the portal bracket includes a main beam and two height-adjustable outriggers respectively installed under both sides of the main beam, and the main beam is composed of a straight beam 1 and two left and right sides of the straight beam 1. The telescopic beam 2 is composed of a telescopic beam 2 at the end, the telescopic beam 2 has a plug-in end and a fixed end, the plug-in end of the telescopic beam 2 is installed inside the straight beam 1, and the fixed end of the telescopic beam 2 is fixedly installed on the On the top of the height-adjustable outrigger, the straight beam 1 is provided with a variable-span driving mechanism for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com