Corona machine

A technology of corona machine and corona roller, applied in the field of corona machine, can solve the problems of air breakdown, effective expansion of film surface, inconsistent traction force, etc., and achieve the effect of preventing reverse corona and improving corona stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

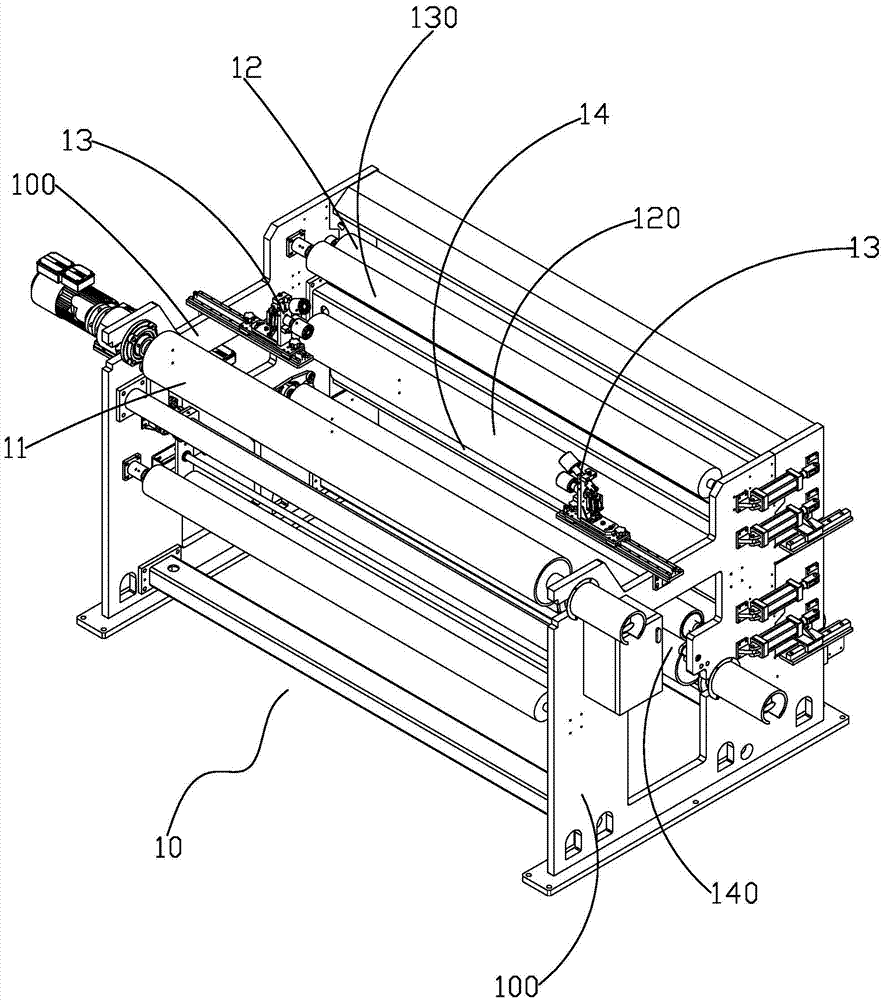

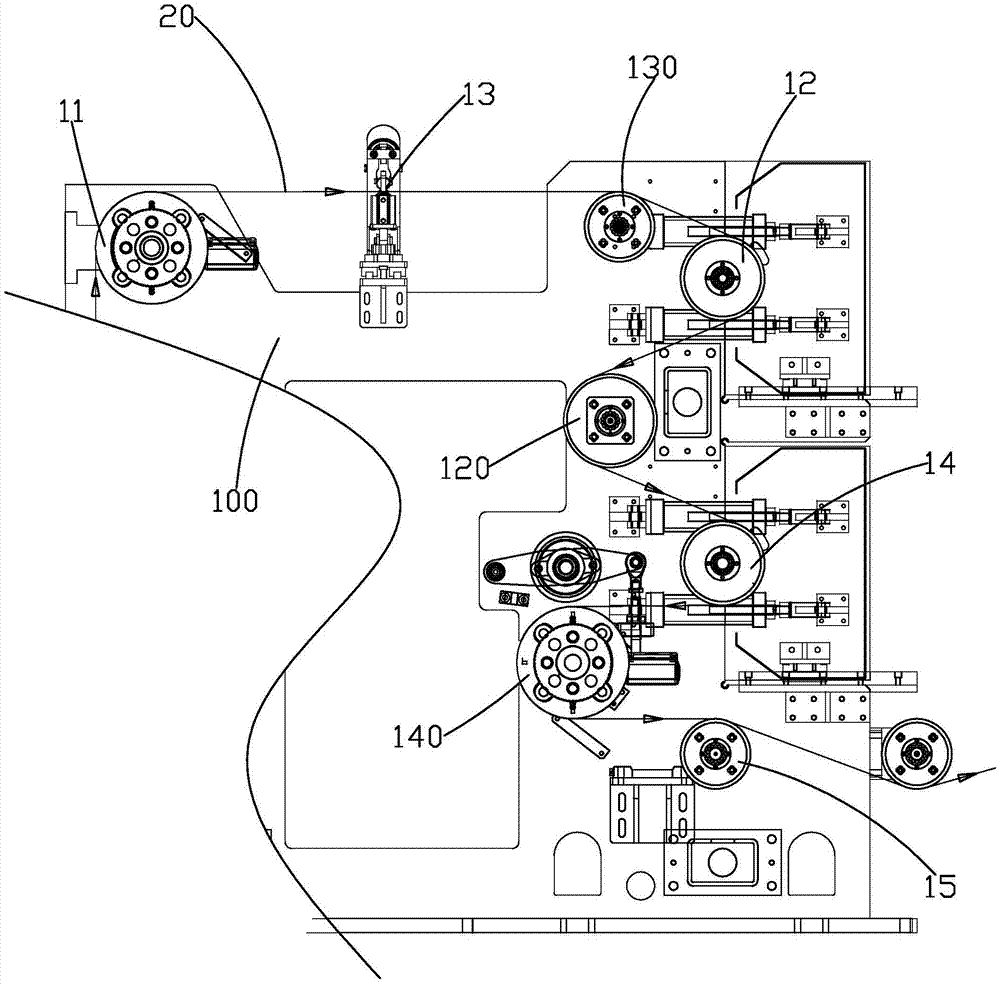

[0014] refer to figure 1 , figure 2 ( figure 2 The direction of the middle arrow indicates the direction of workpiece movement), a corona machine, including a corona machine main body 10, the front and rear sides of the upper middle part of the corona machine main body 10 are respectively provided with front traction rollers 11 for pulling the workpiece to move and for The first corona roller 12 for the corona treatment of the workpiece, two expansion rollers installed on the two side plates 100 of the main body 10 of the corona machine respectively are arranged between the front traction roller 11 and the first corona roller 12. Roller 13, here, the two unfolding rollers 13 are movably installed on the two side plates 100 of the main body 10 of the corona machine through two linear guide rails, and the two unfolding rollers 13 can move toward each other along the two linear guide rails. Or away from it to be suitable for workpieces 20 of different widths, the first corona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com