Device for flattening membrane surface before thermal-shrink membrane rolling

A technology of flattening device and heat shrinkable film, which is applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problem of wrinkling of the film surface, and achieve the effect of improving the flatness and the winding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

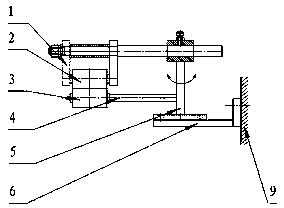

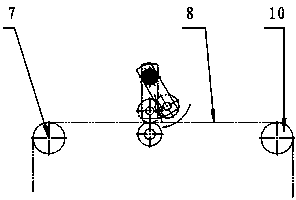

[0015] Such as figure 2 As shown, the film surface flattening device before the heat shrinkable film is rolled is arranged between the rear guide roller 10 and the front guide roller 7, as figure 1 As shown, the flattening device includes a fixed seat 6, a pressure roller 2 and a fixed roller 3, the fixed seat 6 is horizontally fixed on the equipment installation body 9, a rotating bracket 5 is vertically installed on the fixed seat 6, and a The fixed roller support rod 4, the fixed roller 3 is rotatably supported on the fixed roller support rod 4 through the left bearing and the right bearing, the upper end of the rotating bracket 5 is horizontally installed with a pressure roller support rod, and the pressure roller cage 1 is rotatable Supported on the pressure roller support bar, the pressure roller 2 is rotatably supported on the pressure roller cage 1 through the left bearing and the right bearing, and the pressure roller 2 is opposite to and parallel to the fixed roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com