Ultraviolet curing adhesive for temporary protection in aluminum surface anodizing process and preparation method thereof

A treatment process and temporary protection technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as high labor costs, difficult to improve yield, rubber plug breakage, etc., and achieve precise automation control , high efficiency and yield, not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

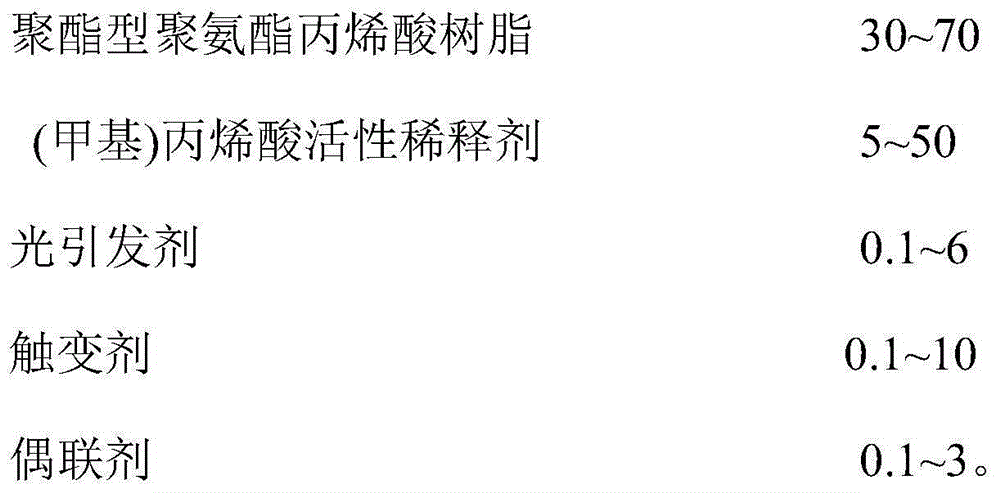

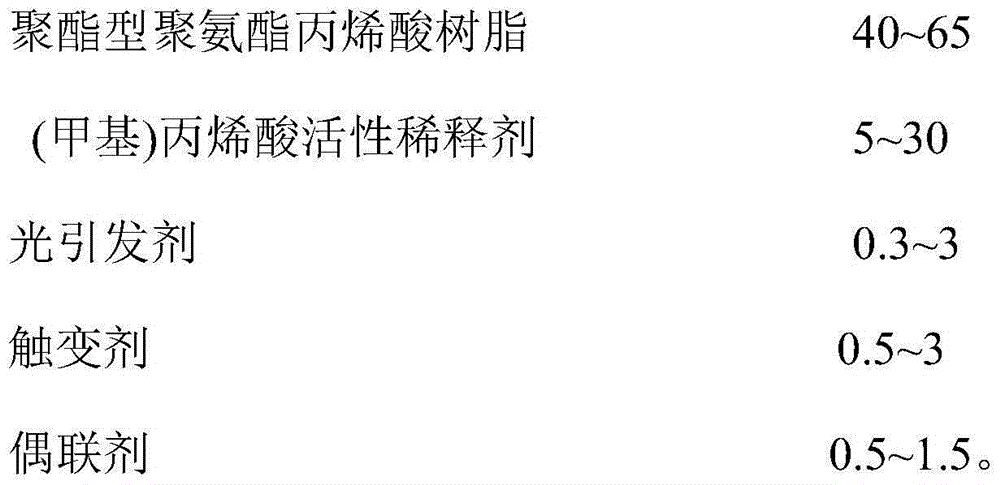

Method used

Image

Examples

Embodiment 1

[0023] Synthesis of polyester polyurethane acrylate PUA-1: 100 grams of polyester diol with a molecular weight (Mn) of 1000 and a hydroxyl value of 112 was vacuum dehydrated at 120°C for 1 hour, and the dehydrated polyester diol , 26.64 grams of isophorone diisocyanate and 10 grams of isobornyl acrylate are put into the reaction kettle together, add 0.1 grams of dibutyltin dilaurate, react at 78 ° C for 3 hours, add 7.8 grams of hydroxyethyl methacrylate, 0.1 gram of hydroquinone as a polymerization inhibitor, continue to react at 78°C for 2 hours, cool to 45°C and discharge, which is called PUA-1.

Embodiment 2

[0025] Synthesis of polyester polyurethane acrylate PUA-2: 100 grams of polyester diol with a molecular weight (Mn) of 2000 and a hydroxyl value of about 56 was vacuum dehydrated at 120°C for 1 hour, and the dehydrated polyester diol Alcohol, 13.32 grams of isophorone diisocyanate and 10 grams of isobornyl acrylate were put into the reaction kettle together, 0.1 gram of dibutyltin dilaurate was added, reacted at 78 °C for 3 hours, and 6 grams of hydroxypropyl methacrylate was added, 0.2 g of hydroquinone is used as a polymerization inhibitor, continue to react at 78°C for 2 hours, cool to 45°C and discharge, which is called PUA-2.

Embodiment 3-7

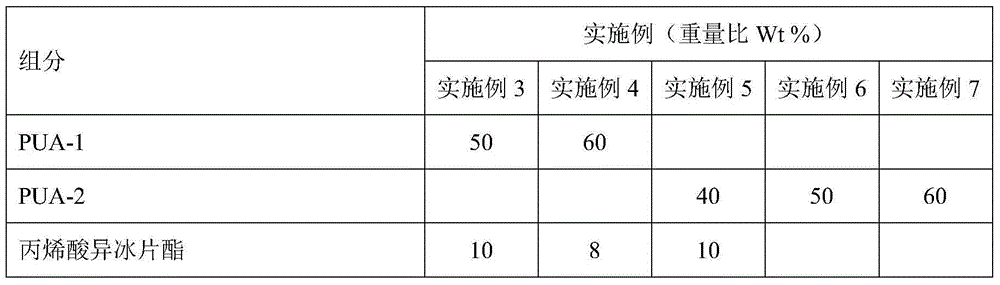

[0027] The PUA-1 and PUA-2 prepared in Example 1 and Example 2 are used as polyester polyurethane acrylate components, and the proportions are carried out according to the contents of each component in Table 1, and they are stirred and mixed in a planetary stirring tank until uniform, and then pumped Vacuum defoaming, discharge.

[0028] Table 1

[0029]

[0030]

[0031] Note: TS-720 and TS-530 are the trademarks of CABOT; R202 is the trademark of Evonik AEROSIL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com