Food-grade heat-resistant and wear-resistant conveyor belt cover rubber and preparation method thereof

A conveyor belt, food-grade technology, applied in the field of food-grade heat-resistant and wear-resistant conveyor belt cover rubber and its preparation, to achieve the effect of prolonging service life and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

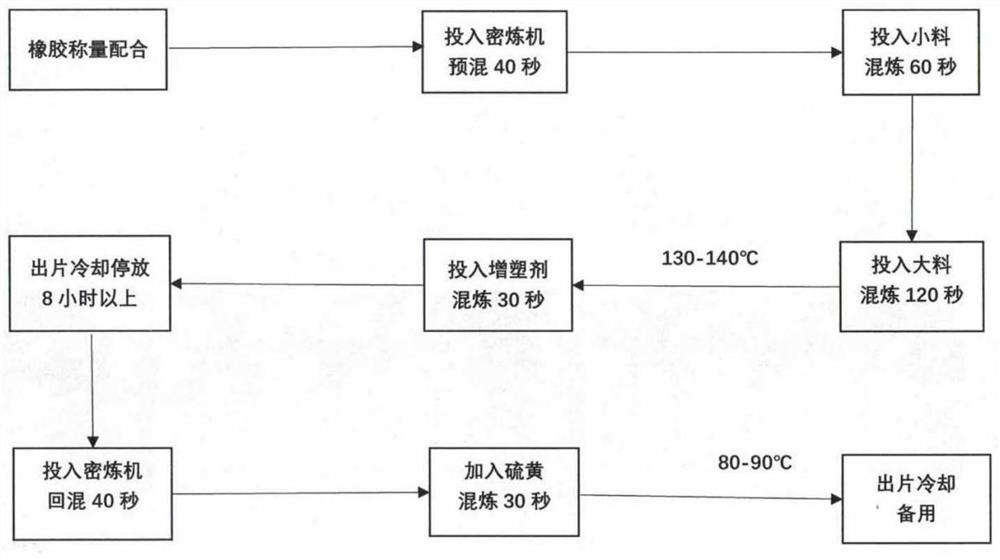

Method used

Image

Examples

Embodiment Construction

[0040] Through the statistics of edible salt production enterprises over the years, the following parameters are obtained for the conveyor belts that need to be used:

[0041] 1. Hygienic requirements (GB2762 and GB2760 standard requirements)

[0042] Evaporation residue of 4% acetic acid soaking solution≤1000mg / L

[0043] Evaporation residue of n-ethane soaking solution≤2000mg / L

[0044] Potassium permanganate consumption in water soaking solution≤70mg / L

[0045] Heavy metal (calculated as Pb) 4% acetic acid soaking solution≤1mg / L

[0046] 2. Heat-resistant requirements (GB / T20021 canvas core heat-resistant conveyor belt type T1)

[0047] After the sample is aged at 100℃×7d

[0048] Minimum strength value ≥ 12MPa

[0049] Change in strength ≤ 25% compared with before aging

[0050] The lowest elongation at break ≥ 200%

[0051] Change in elongation at break ≤ 50% compared with before aging

[0052] Maximum hardness≤85IRHD

[0053] Change in hardness ≤ 20IRHD compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com