Method for continuously preparing butanedinitrile

A technology for succinonitrile and acrylonitrile, which is applied in the field of reactors for continuous preparation of succinonitrile, can solve the problems of difficult production scale-up, poor intrinsic safety, and low production efficiency, and achieves reduced hazards, high production efficiency, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

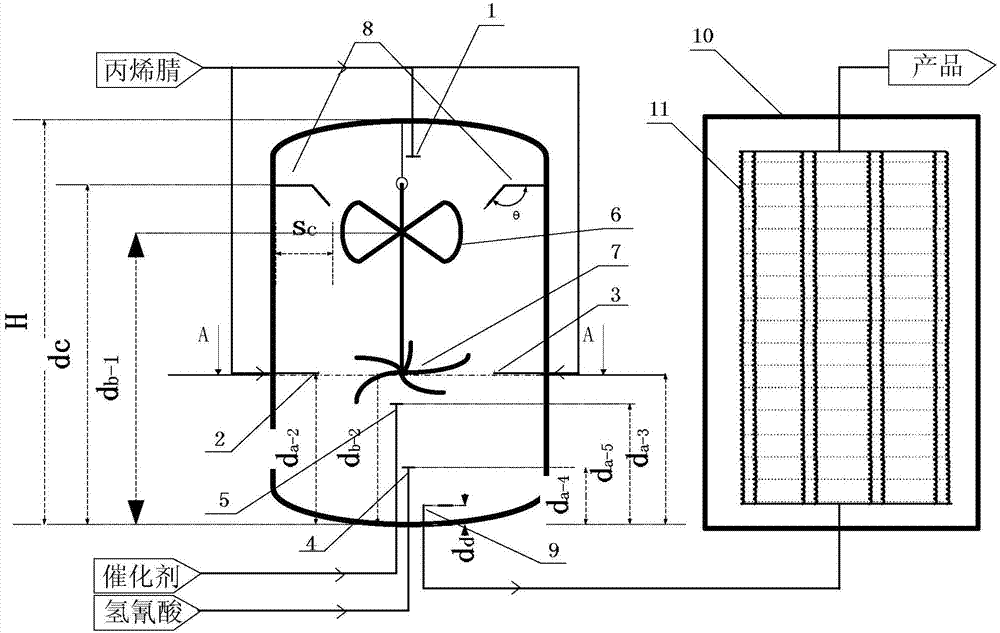

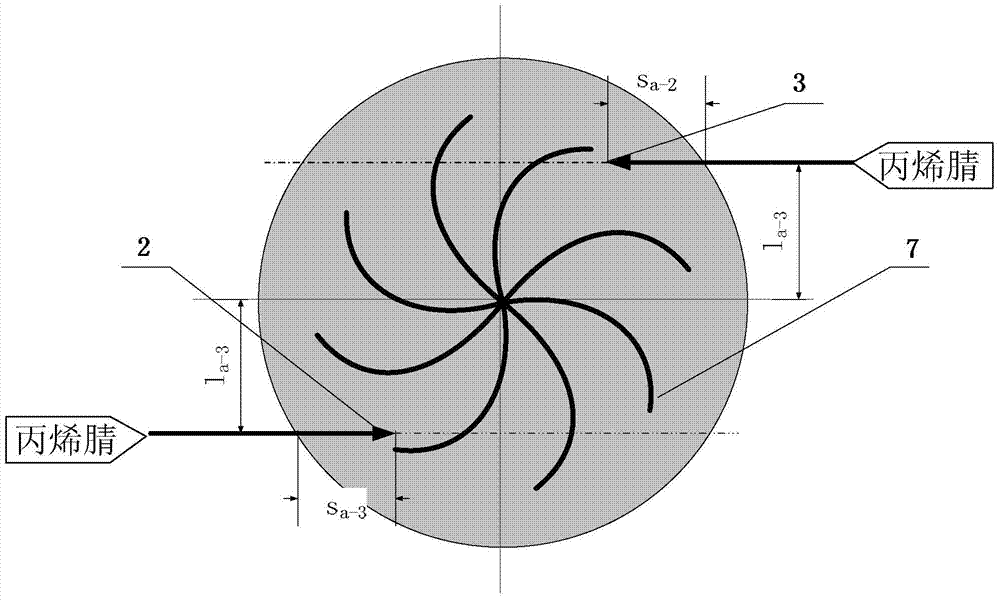

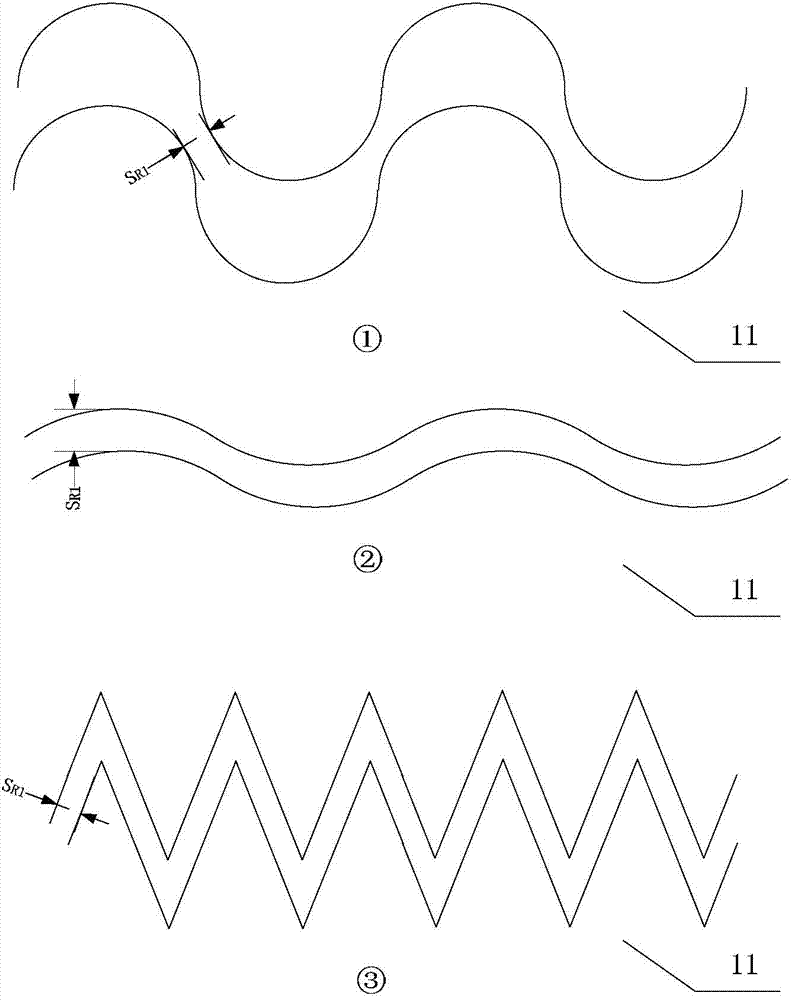

[0050] Example 1 as figure 1 As shown, the reactor for preparing succinonitrile mainly includes two parts of a small mixing tank and a microreactor, wherein the volume of the small mixing tank is 1L. The small mixing kettle includes five feeding nozzles (1) (2) (3) (4) (5), mixing agitator (6) (7), baffle plate (8) and outlet (9), etc. . Specifically, the top acrylonitrile feed nozzle (1) is located at the center of the shaft of the small mixing kettle, with a height d a-1 It is 90-95% of the kettle height H; two acrylonitrile feed nozzles (2) and (3) on the side of the small mixing kettle, height d a-2 、d a-3 35% of the kettle height H, such as figure 2 As shown, the straight lines where they are located are parallel to each other and have the same distance from the center of the circle, and the distance from the center of the circle is l a-2 , l a-3 It is 25% of the diameter D, and the length of the feed port in the kettle is s a-2 , s a-3 It is 20% of the diameter ...

Embodiment 2

[0056] The reactor structure is the same as in Example 1, except that the volume of the small mixing tank is 0.2L. Such as figure 1 As shown, two acrylonitrile feed nozzles (2) and (3) on the side of the small mixing tank, height d a-2 、d a-3 30% of the kettle height H, such as figure 2 As shown, the straight lines where they are located are parallel to each other and have the same distance from the center of the circle, and the distance from the center of the circle is l a-2 , l a-3 It is 30% of the diameter D, and the length of the feed port in the kettle is s a-2 , s a-3 It is 15% of the above-mentioned circle diameter D; the hydrocyanic acid feed nozzle (4) at the bottom is located on the center of the shaft of the mixing kettle with a height of d a-4 It is 8% of the kettle height H; the bottom catalyst feed nozzle (5), located on the center of the mixing kettle axis, has a height of d a-5 It is 18% of the kettle height H. Such as figure 1 As shown, the middle an...

Embodiment 3

[0062] The reactor structure is the same as in Example 1, except that the volume of the small mixing tank is 0.35L. Two acrylonitrile feed nozzles (2) and (3) on the side of the small mixing tank, height d a-2 、d a-3 40% of the kettle height H, such as figure 2 As shown, the straight lines where they are located are parallel to each other and have the same distance from the center of the circle, and the distance from the center of the circle is l a-2 , l a-3 It is 28% of the diameter D, and the length of the feed port in the kettle is s a-2 , s a-3 It is 18% of the above-mentioned circle diameter D; the bottom prussic acid feed nozzle (4) is located on the center of the shaft of the mixing kettle, with a height of d a-4 It is 10% of the kettle height H; the bottom catalyst feed nozzle (5), located on the center of the shaft of the mixing kettle, has a height of d a-5 It is 20% of the kettle height H. The middle and upper part of the mixing agitator is a propulsive stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com