High-precision peristaltic pipeline crawl device and control method thereof

A technology of a pipeline crawler and a control method, which is applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of poor adaptability, difficulty in adapting to pipes of different diameters, low depth accuracy of crawler, etc., to achieve dynamic wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments.

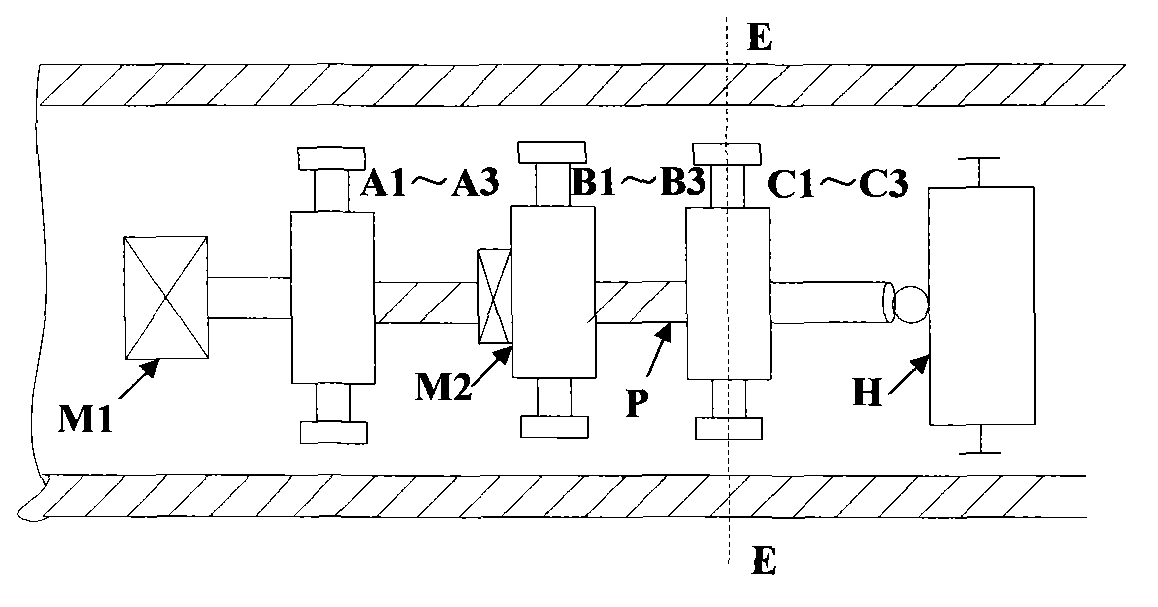

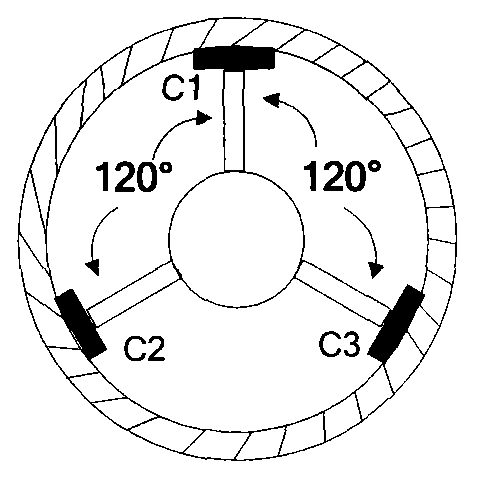

[0021] refer to figure 1 and figure 2 , The peristaltic pipeline crawler includes three three-claw mechanisms, a screw P and a pipeline parameter measuring head H; the motor M1 drives the screw P to rotate, and the motor M2 drives the claws B1 to B3 to expand and contract. The screw P is the torso of the crawler, and it is universally rigidly connected with the pipe parameter measuring head H. The claws A1~A3, B1~B3, and C1~C3 are radially distributed symmetrically. Telescopic three-jaw mechanism. The connection modes between each three-jaw mechanism and the screw rod are different. The three-claw mechanism formed by claws B1~B3 is threadedly connected with the screw P, the three-claw mechanism formed by claws A1~A3, C1~C3 is connected with the screw P by rollers, and the claws A1~claw The three-claw mechanism formed by A3 and claws C1 to C3 cannot be relatively disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com