Direct backheating burned flame type heating stove and working method

A heating furnace, direct technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of furnace pressure fluctuation, shorten the life of the furnace body, increase the furnace accident rate, etc., achieve precise automatic control and adjustment, and reduce furnace accidents efficiency, and the effect of improving the furnace operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

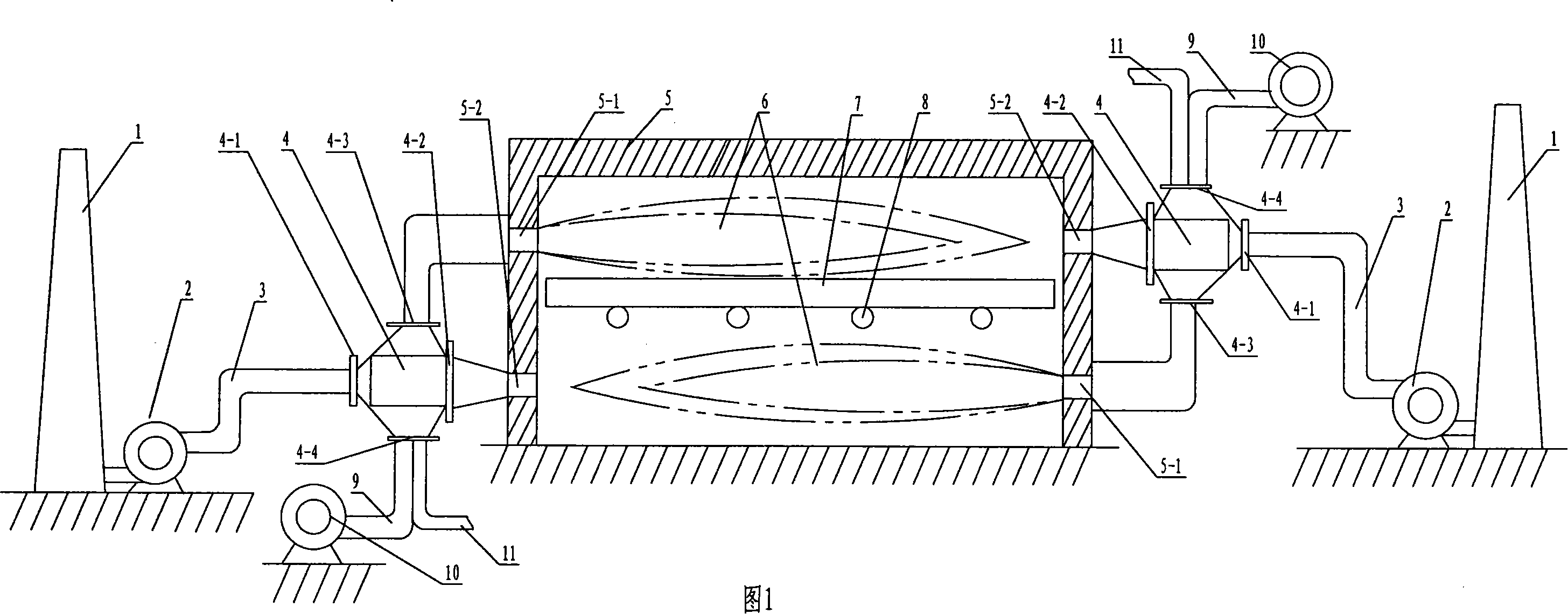

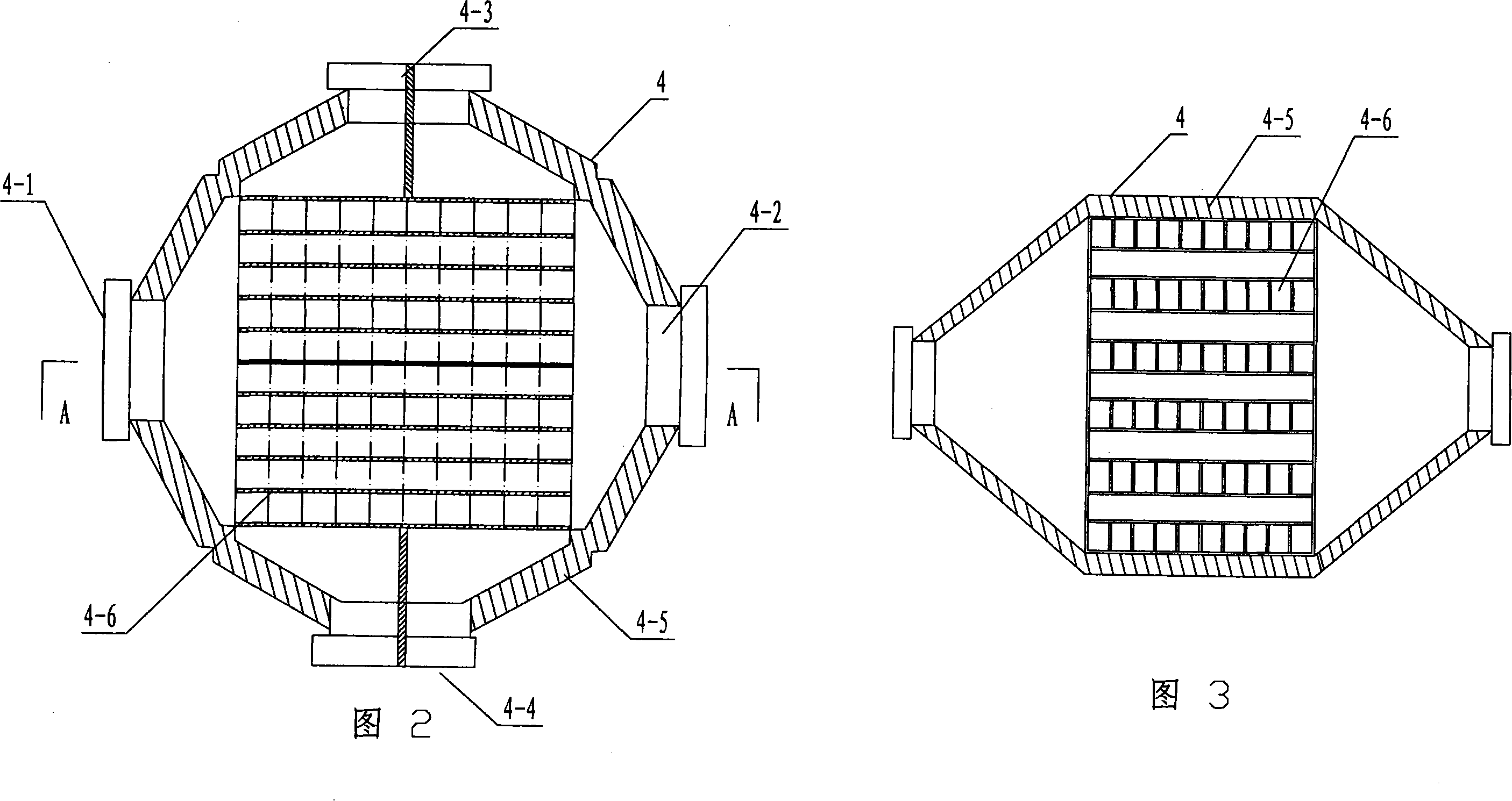

[0022] Referring to Fig. 1, the composition of the flame type heating furnace of direct regenerative combustion of the present invention comprises furnace body 5, heat exchange device, air supply device and smoke exhaust device, and the two sides of furnace body 5 are respectively provided with air fuel inlet 5-1 and The high-temperature flue gas outlet 5-2, wherein the air fuel inlet on each side is set corresponding to the position of the high-temperature flue gas outlet on the other side. The working status of the two ports on the same side of the heating furnace body is different, and when the upper port on one side is in the state of exhausting smoke, the lower port is in the state of fuel and air supply, while the upper port on the other side is in the state of fuel and air supply. The lower port is in the state of exhausting smoke. The smoke exhaust device is composed of a flue 3, an induced draft fan 2, and a chimney 1 connected to each other, and the air supply device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com