Preparation method for siliceous earth/FeOOH composite materials in micro-nano structure

An iron oxyhydroxide, micro-nano structure technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as difficult separation and easy agglomeration, and achieve the effects of convenient handling, low reaction temperature, and automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of diatomite / iron oxyhydroxide composite material with micro-nano structure, comprising the following steps:

[0026] (1) First weigh 10g of diatomaceous earth, add it to 150mL 2M hydrochloric acid solution, transfer it to a 250mL three-necked flask, and heat it in a water bath to 90 o C and stirred for 24 h, washed repeatedly with deionized water and ethanol until the solution was neutral, and dried by suction filtration.

[0027] (2) First, mix 60mL of deionized water and 60mL of ethylene glycol evenly in a 250mL volumetric flask, then take 90mL into the 250mL volumetric flask, and weigh 1.98g of FeSO 4 ·7H 2 0, 5 grams of diatomaceous earth after cleaning are added in the volumetric flask, and ultrasonicated for 5 minutes;

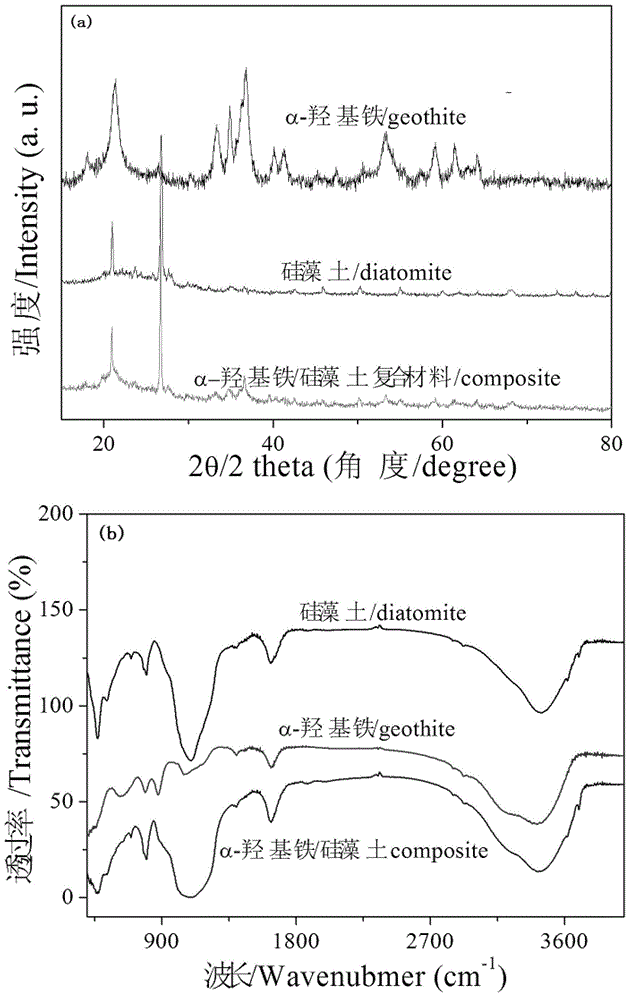

[0015] (2) The α-FeOOH of the above-mentioned composite material presents a nanostructure with high crystallinity and high purity;

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com