Evaporator apparatus and method for modulating cooling

a technology of evaporator and cooling surface, which is applied in the direction of refrigeration machines, light and heating apparatuses, refrigeration components, etc., can solve the problems of single-stage air conditioning systems, ineffective inability to effectively facilitate the heat transfer between the refrigerant and the evaporator surface, etc., to achieve greater turndown capability and increase energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0130]A computer simulation showed the benefits of a modulating compressor design in an air conditioning system. A simulation was written in the Engineer Equation Solver compiler to accurately model the operation of a reciprocating compressor at different speeds and compression ratios. In the simulation, the compressor powered a refrigeration cycle with a variety of refrigerant types, air temperatures, coil heat transfer coefficients, coil sizes, fan speeds and / or expansion pressure drops. This simulation was developed to test and / or compare modulating air conditioning system designs to conventional systems.

[0131]A set of experimental parameters were refined to include air conditioning systems ranging from 2.5 to 3 tons of refrigeration capacity, with an indoor temperature of 70 degrees Fahrenheit (21.1 degrees Celsius) and an outdoor temperature of 80 degrees Fahrenheit (26.7 degrees Celsius). The coil sizes, heat transfer coefficients, compressor speed, compression ratio, physical...

example 2

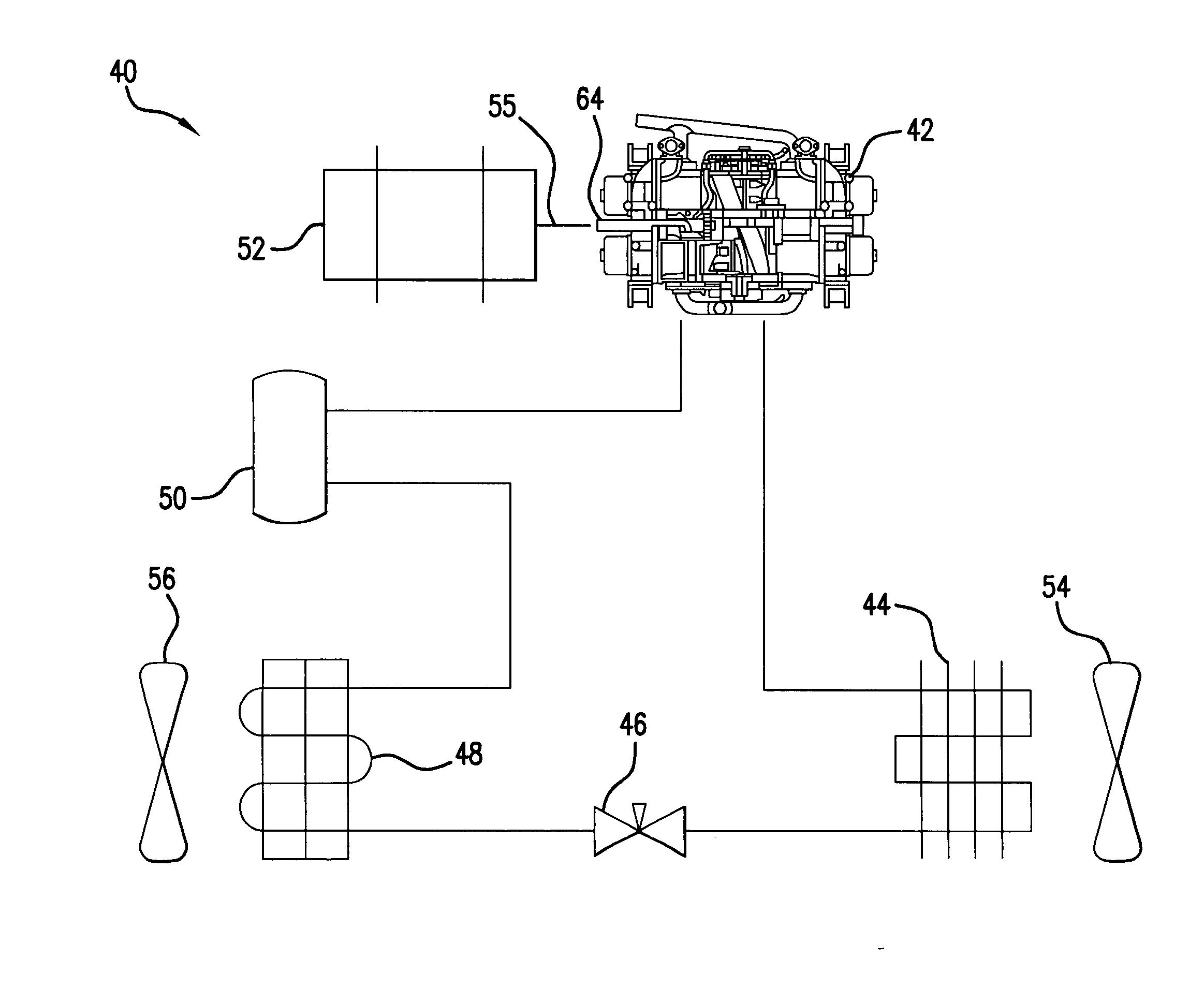

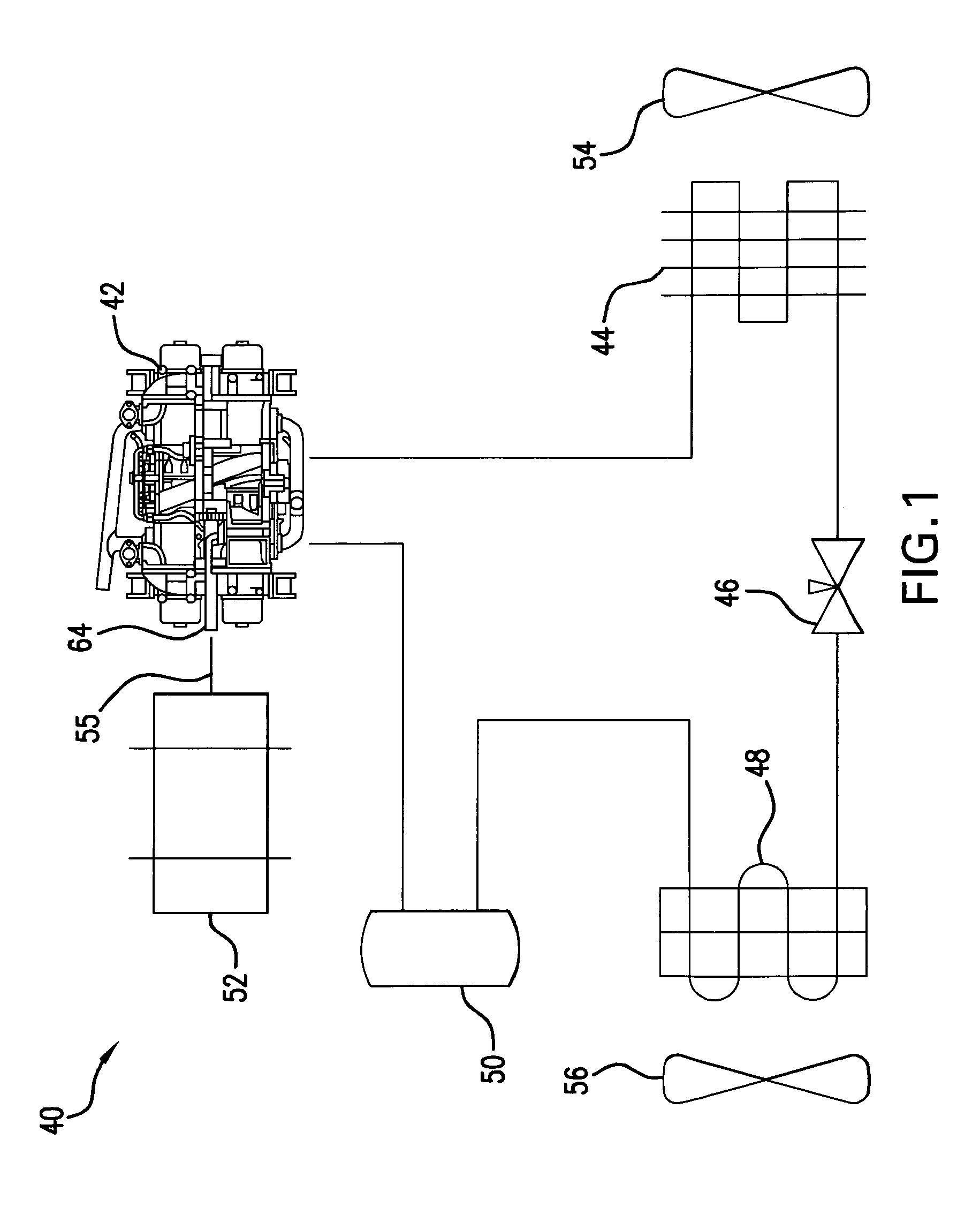

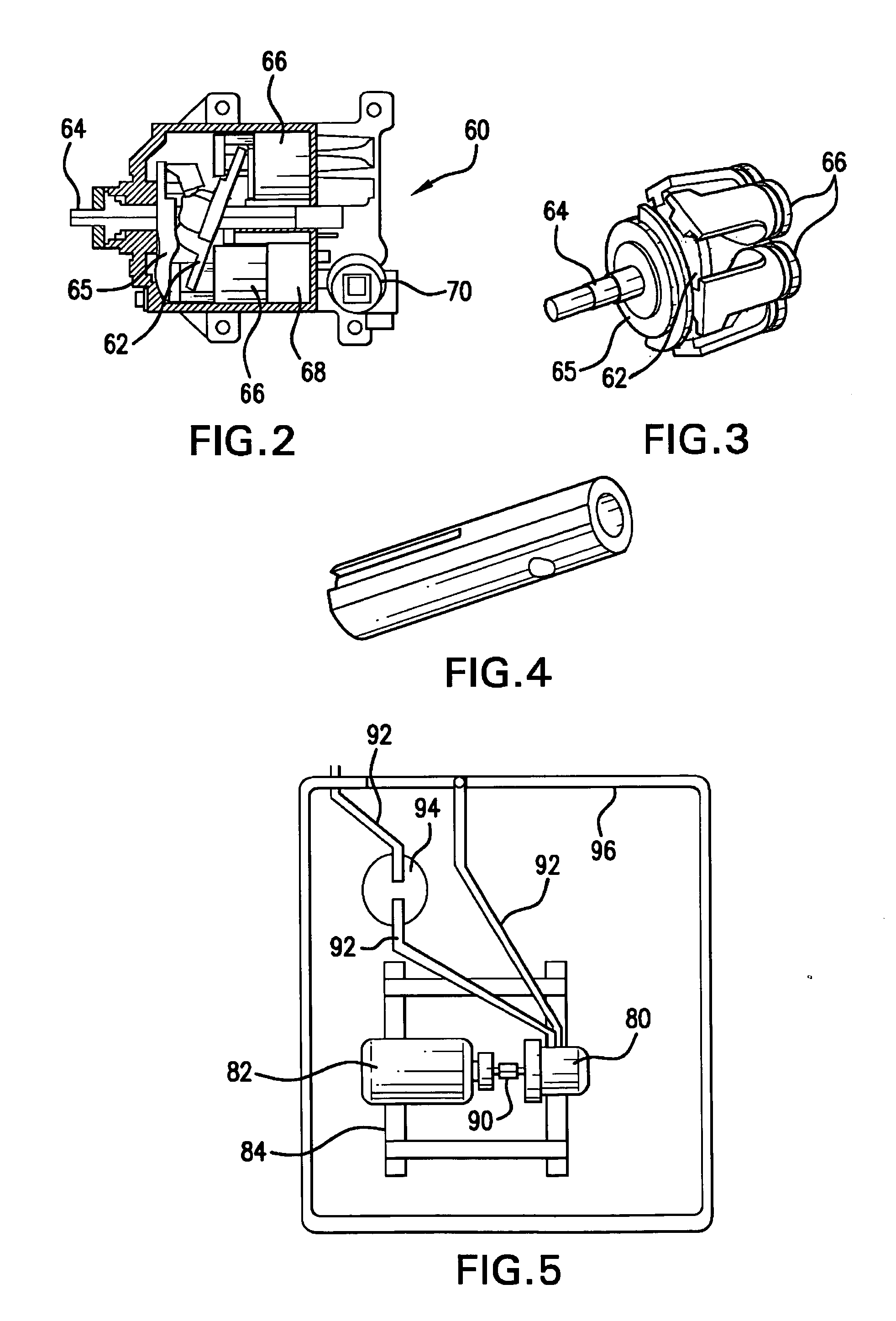

[0132]A variable displacement modulating air conditioner was fabricated and used for testing. A Denso 7SEU16C swashplate compressor was mounted on a test platform and was driven by a 5 HP Dayton motor with a variable speed pulley drive. The compressor was controlled by a Labview console developed specifically for the modulating air conditioner test. The test included refrigerant compatibility, oil compatibility, power requirements, system state temperatures, system state pressures and / or control response.

[0133]Initial testing was performed on an R-22 based system, with a mineral oil lubricant having a light viscosity. The test was conducted with rubber quick-disconnect hose and suction line filters. After satisfactory results were achieved on the variable speed test platform, a direct coupling from the motor to the compressor was engineered and machined. The compressor utilized a screw-on pulley with a set screw on the attaching hub. A converting shaft replaced the pulley with a ⅝″ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com