Fume desulfurizing and denitrifying device based on magnesia and method

A technology of desulfurization and denitrification, magnesium oxide, applied in the direction of chemical instruments and methods, separation methods, magnesium sulfate, etc., can solve the problems of secondary pollution, desulfurization by-products such as calcium sulfate, low value, and difficult to scale up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

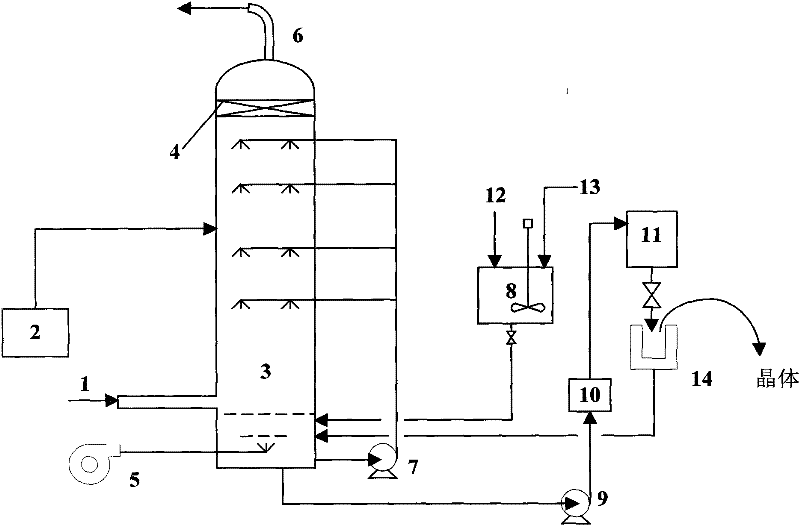

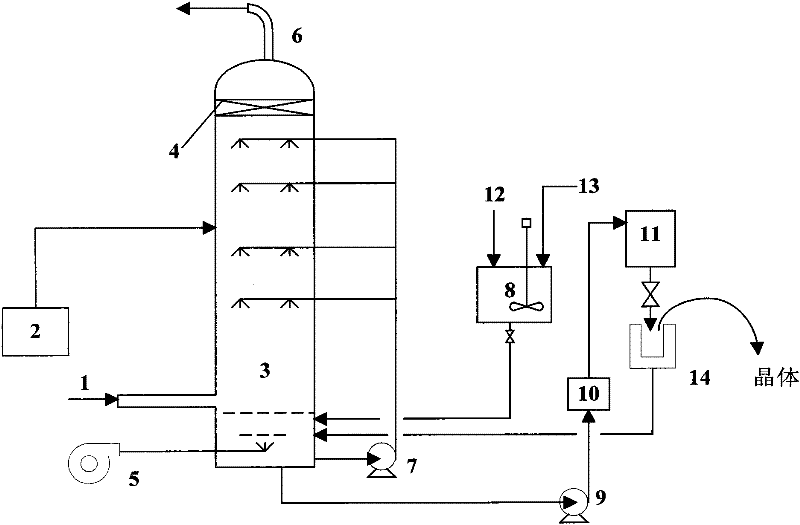

[0040] Flue gas condition: 15000Nm 3 / h, SO 2 Concentration 1200ppm (3428mg / Nm 3 ), NO concentration 460ppm (616mg / Nm 3 ), the temperature is 150℃. Magnesium oxide slurry concentration 10%, volume 3.7m 3 .

[0041] The flue gas enters the desulfurization tower (the desulfurization tower is a spray tower), the ozone addition amount is 15.5kg / h, and the absorption liquid (including Cu 2+ The concentration of 50ppm) is sprayed into the tower from the upper and lower parts of the ozone inlet at a flow rate of 15t / h. SO in the flue gas at the top outlet 2 The content is 110mg / Nm 3 , the NO concentration is 38 mg / Nm 3 , the desulfurization rate is 96.8%, and the denitration rate is 93.8%. After desulfurization and denitrification, the flue gas enters the chimney from the top of the tower after being defogged by the mist eliminator. After 10 hours, a mixed solution containing 25.2% of magnesium sulfate and 5.78% of magnesium nitrate was obtained. A part of the absorption l...

Embodiment 2

[0043] Flue gas condition: 6500Nm 3 / h, SO 2 Concentration 450ppm (1286mg / Nm 3 ), NO concentration 230ppm (308mg / Nm 3 ), the temperature is 140℃. Magnesium oxide slurry concentration 10%, volume 3.0m 3

[0044] The flue gas enters the desulfurization tower (the desulfurization tower is a spray tower), the ozone addition amount is 3.36kg / h, and the absorption liquid (of which Fe 2+ The concentration of 80ppm) is sprayed into the tower from the upper and lower parts of the ozone inlet at a flow rate of 10t / h. SO in the flue gas at the top outlet 2 The content is 40mg / Nm 3 , the NO concentration is 20 mg / Nm 3, the desulfurization rate is 96.9%, and the denitration rate is 93.5%. After desulfurization and denitrification, the flue gas enters the chimney from the top of the tower after being defogged by the mist eliminator. After 47 hours, a mixed solution containing 23.6% of magnesium sulfate and 7.2% of magnesium nitrate was obtained. A part of the absorption liquid wa...

Embodiment 3

[0046] Flue gas condition: 45000Nm 3 / h, SO 2 Concentration 320ppm (914mg / Nm 3 ), NO concentration 670ppm (897mg / Nm 3 ), the temperature is 160℃. Magnesium oxide slurry concentration 15%, volume 7m 3 .

[0047] The flue gas enters the desulfurization tower (the desulfurization tower is a spray tower), the ozone addition amount is 61.3kg / h, and the absorption liquid (including Co 2+ The concentration of 100ppm) is sprayed into the tower from the upper and lower parts of the ozone inlet at a flow rate of 30t / h. SO in the flue gas at the top outlet 2 The content is 20mg / Nm 3 , the NO concentration is 67 mg / Nm 3 , the desulfurization rate is 97.8%, and the denitration rate is 92.5%. After desulfurization and denitrification, the flue gas enters the chimney from the top of the tower after being defogged by the mist eliminator. After 21 hours, a mixed solution containing 22.6% of magnesium sulfate and 27.6% of magnesium nitrate was obtained. A part of the absorption liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com