A large radiator with spacing adjustment structure and its working method

A technology for adjusting structures and radiators, which is applied to indirect heat exchangers, lighting and heating equipment, and structural components of electrical equipment, etc. Cooling cycle, the effect of strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

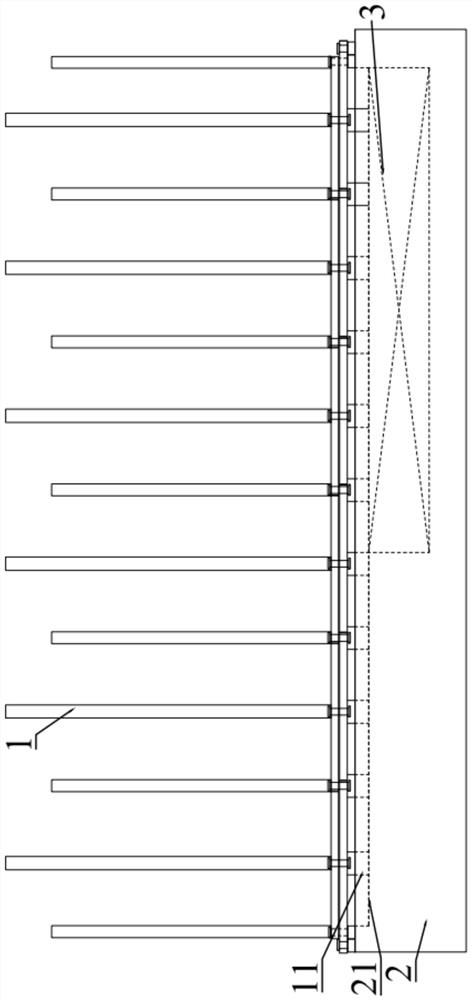

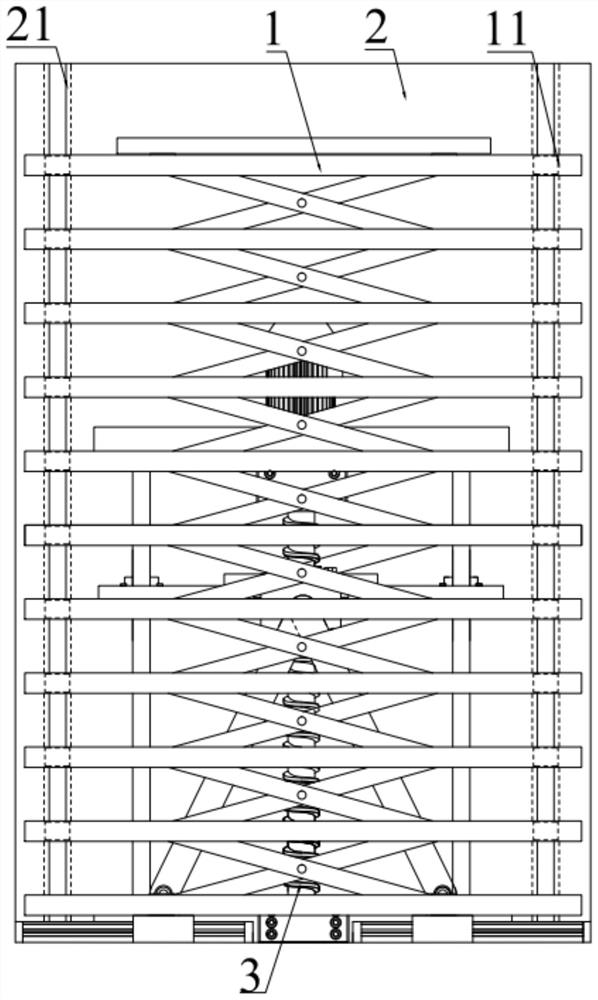

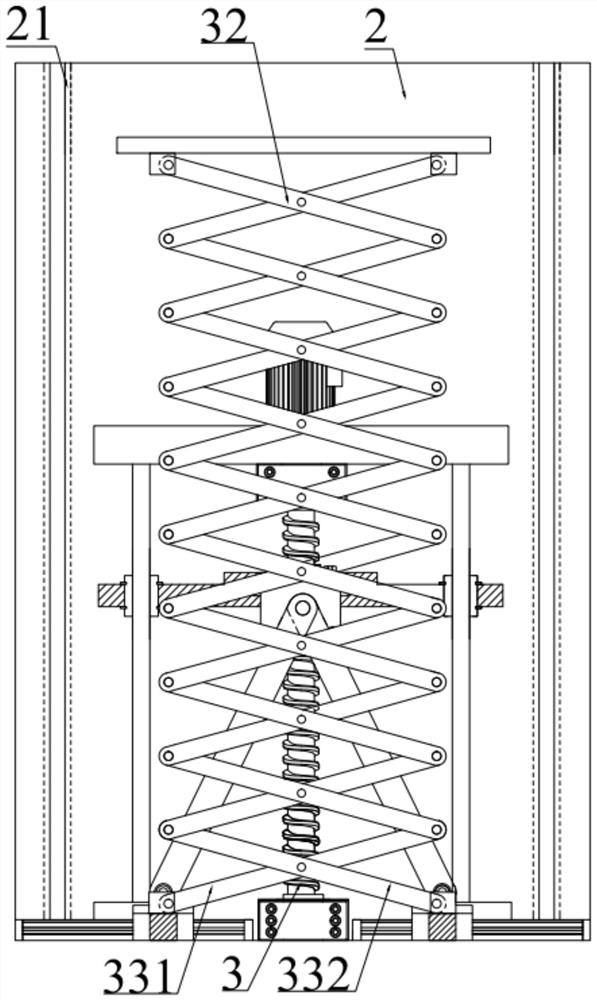

[0045] like figure 1 , 2 The shown large-scale radiator with a spacing adjustment structure includes a set of radiating fins 1, a radiator base 2 and a radiating fin spacing adjusting device 3, the set of radiating fins 1 are arranged in a row, and a set of radiating fins is The lower end of the fins 1 is connected to the cooling fin spacing adjustment device 3, the lower end of the cooling fin 1 is slidably connected to the radiator base 2, and the cooling fin spacing adjustment device 3 is arranged in the radiator base 2, and The heights of the set of heat dissipation fins 1 are different.

[0046] The radiator base 2 is in the shape of a rectangular flat plate, and the upper end surface of the radiator base 2 is symmetrically provided with two radiating fin guiding chutes 21, and the two radiating fin guiding chutes 21 are respectively located at the radiating fins. On both sides of the fin spacing adjusting device 3 , the two fin guide chutes 21 are arranged along the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com