A plug-in high-efficiency heat conduction radiator

A radiator and high-efficiency technology, which is applied in the field of plug-in high-efficiency heat-conducting heat sinks, can solve the problems of easy accumulation of dust and impurities in the slot, low heat conduction efficiency, and reduced thermal conduction effect, and achieves favorable heat conduction and high heat conduction efficiency. , the effect of not easy to accumulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

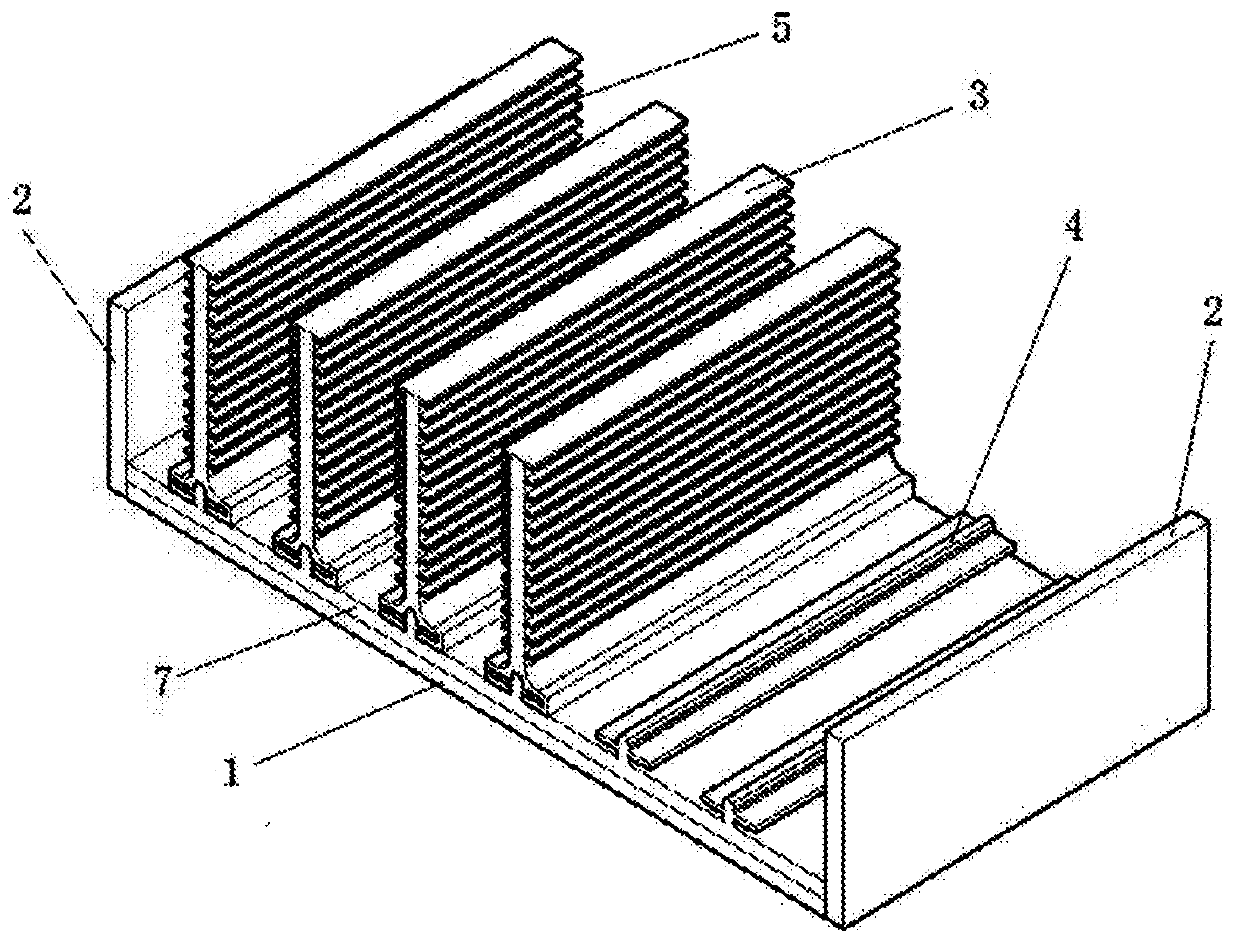

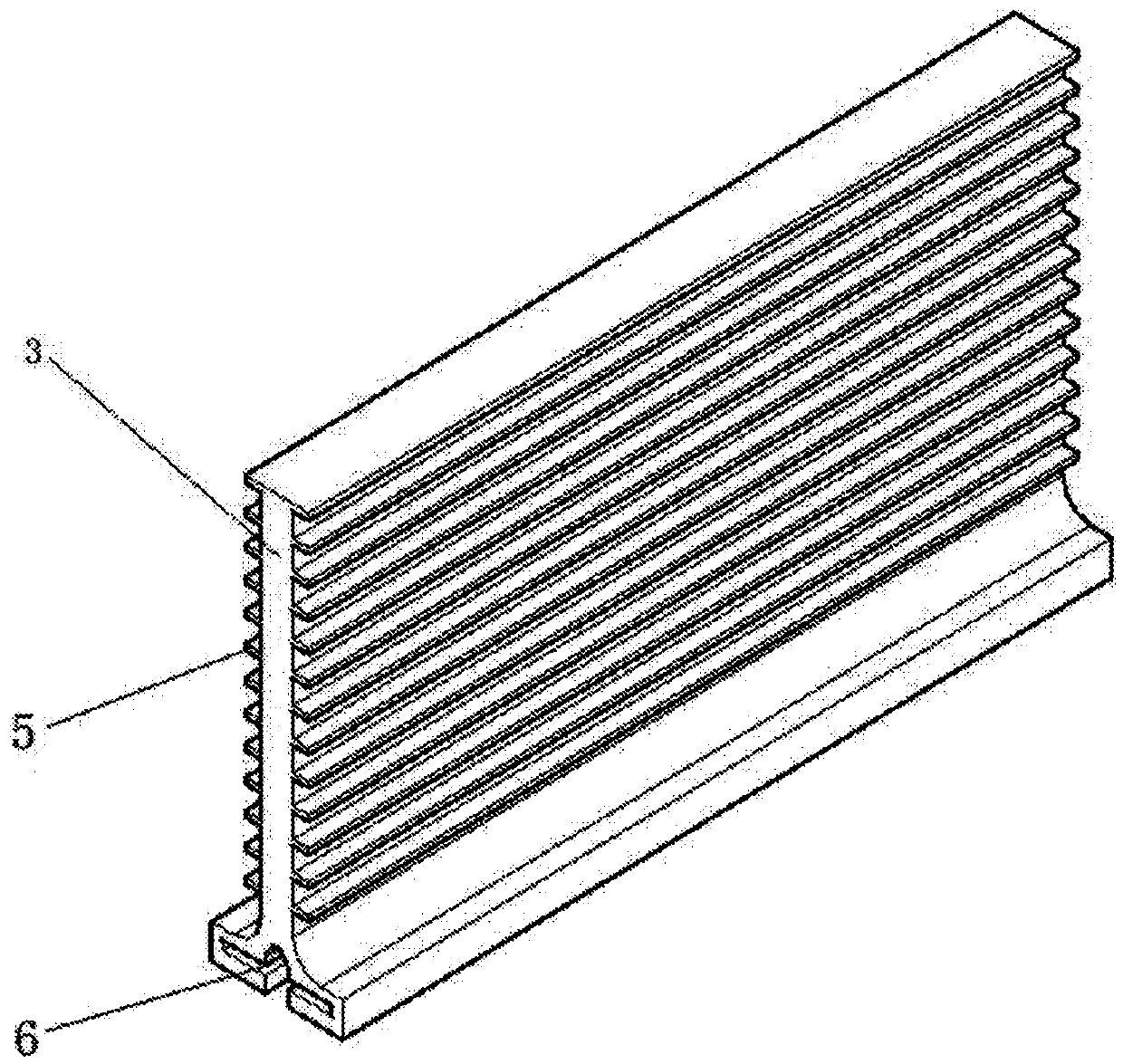

[0025] A plug-in high-efficiency heat conduction radiator described in the present invention, such as figure 1 , figure 2 As shown, it includes a substrate 1, a guardrail 2 and a heat sink 3; the guardrail 2 is made of heat-insulating ceramics, which has a beautiful appearance and ensures the structural stability of the radiator; the guardrail 2 is located on both sides of the substrate 1; the substrate 1 is provided with a layer of heat-conducting layer 7; the heat-conducting layer 7 is provided with protruding "ten"-shaped heat-conducting rails 4 evenly distributed at equal intervals; the heat sink 3 is fixedly inserted on the heat-conducting rail 4; The bottom of the heat sink 3 is provided with a "ten"-shaped slot 6; the size of the slot 6 matches the size of the heat conduction rail 4; the two sides of the heat sink 3 are symmetrically provided with the word "one" Type heat dissipation fin 5, heat dissipation fin 5 and heat dissipation fin 3 adopt aluminum alloy integra...

Embodiment 2

[0029] A plug-in high-efficiency heat conduction radiator described in the present invention, such as figure 1 , figure 2 As shown, it includes substrate 1, guardrail 2 and heat sink 3; said guardrail 2 is arranged on both sides of substrate 1; said substrate 1 is provided with a layer of heat conduction layer 7; said heat conduction layer 7 is provided with raised etc. "Ten"-shaped heat-conducting rails 4 evenly spaced; the heat sink 3 is fixedly inserted on the heat-conducting rail 4; the bottom of the heat sink 3 is provided with a "ten"-shaped slot 6; the slot The size of 6 matches the size of the heat conduction rail 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com