Palladium alumina catalyst for production of hydrogen peroxide by anthraquinone process and its preparation method

A palladium alumina, hydrogen peroxide technology, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, etc. direction, can solve the problem of low compressive strength of the catalyst, and achieve the effects of good selectivity balance, high compressive strength and balanced surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

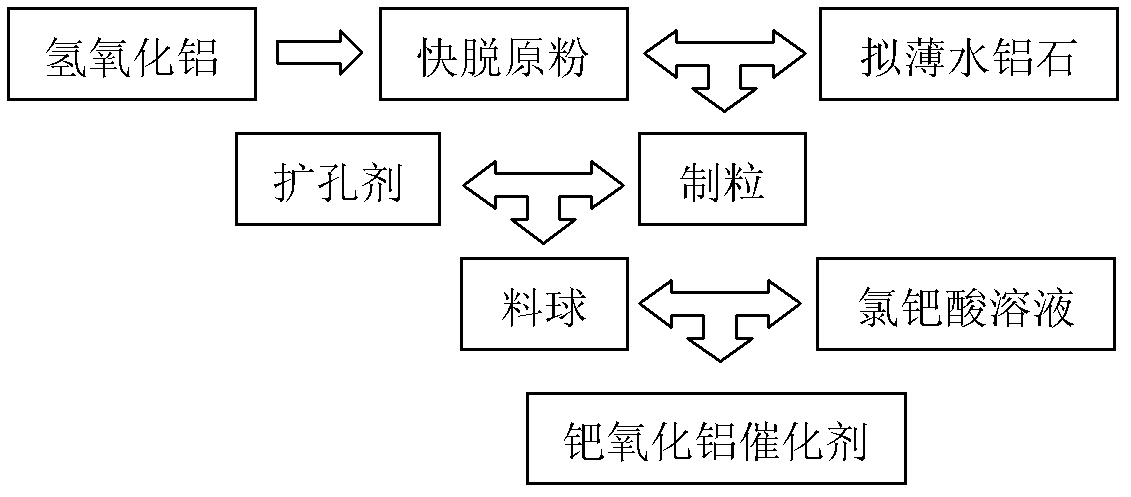

[0085]The aluminum hydroxide is pulverized in a mechanical mill to 1 μm to 50 μm, sent into a flash roaster, and flash roasted for 0.5 seconds at an inlet temperature of 1000°C to obtain a quick dehydration powder; weigh pseudo-boehmite, Mix the obtained quick-release raw powder and pseudo-boehmite according to the mass percentage of 80:20, and the mixing time is 1 hour, then send the mixed material into a pan granulator for granulation, and use water It is a binder; on the disc granulator, add a pore-enlarging agent to make the pore size reach a nonlinear and asymmetric distribution on the cross-section of the carrier to obtain a pellet; the pore-expanding agent is cellulose; send the formed pellet into the rolling equipment Carry out surface treatment in the process, grind off the protruding part of the surface, and preliminarily grind off part of the surface attached powder to reduce wear; wherein, the speed of surface treatment is 40 rpm, the treatment time is 5min, and the...

Embodiment 2

[0088] The aluminum hydroxide is pulverized in a mechanical mill to 1 μm to 50 μm, and sent to a flash roaster for 1 second, and the inlet temperature is 1050°C to obtain a quick dehydration powder; weigh pseudo-boehmite, Mix the obtained quick-release raw powder and pseudo-boehmite according to the mass percentage of 95:5, and the mixing time is 1 hour, and then the mixed material is sent into a pan granulator for granulation, and is mixed with water It is a binder; on the disc granulator, add a pore-enlarging agent to make the pore size reach a nonlinear asymmetric distribution in the cross-section of the carrier to obtain a pellet; the pore-expanding agent is cellulose methyl ether; send the formed pellet into Carry out surface treatment in rolling equipment, grind off the protruding part of the surface, and preliminarily grind off part of the surface attached powder to reduce wear; among them, the speed of surface treatment is 40 rpm, the treatment time is 30min, and the po...

Embodiment 3

[0091] The aluminum hydroxide is pulverized in a mechanical mill to 1 μm to 50 μm, and sent to a flash roaster for 0.8 seconds, and the inlet temperature is 1020°C to obtain a quick dehydration powder; weigh pseudo-boehmite, Mix the obtained quick-release raw powder and pseudo-boehmite according to the mass percentage of 90:10, and the mixing time is 1 hour, and then the mixed material is sent into a pan granulator for granulation, and the mixture is mixed with water It is a binder; on the disc granulator, add a pore-enlarging agent to make the pore size reach a nonlinear asymmetric distribution in the cross-section of the carrier to obtain a pellet; the pore-expanding agent is polyethylene glycol; send the formed pellet into Carry out surface treatment in rolling equipment, grind off the protruding part of the surface, and preliminarily grind off part of the surface adhesion powder to reduce wear; among them, the speed of surface treatment is 40 rpm, the treatment time is 20mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com