Method for regenerating anion exchange resin

An anion exchange column and exchange resin technology, applied in the field of ion exchange resin regeneration, can solve the problems of increased processing capacity, long regeneration cycle, and difficult elution of organic impurities, etc., to achieve increased processing capacity, improved regeneration exchange capacity, and resin The effect of long regeneration period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

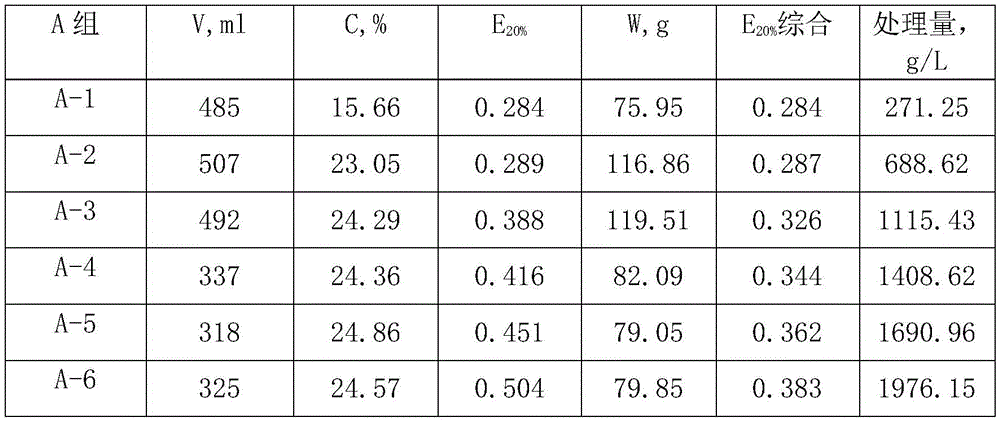

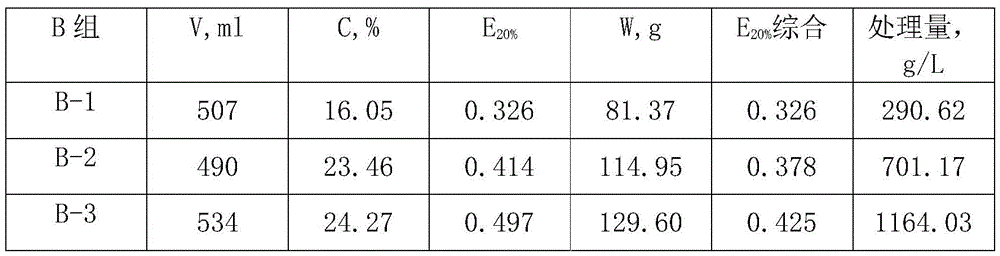

Examples

Embodiment 1

[0021] Alcohol in the alcohol-alkali solution of this embodiment is an example of ethanol solution.

[0022] Under the temperature condition of 25°C, adopt wet packing method, put 300ml of anion exchange resin to be regenerated into a glass chromatography column, the ratio of diameter to height is 1:7, pass 3BV alcohol-alkali solution through the anion at a flow rate of 0.5BV / h For exchange resin, the concentration of sodium hydroxide in the alcohol-alkali solution is 2%, the concentration of ethanol is 70%, and washed with water until the pH is less than or equal to 9. Then, pass 2BV5% hydrochloric acid solution at 0.5BV / h, wash with water until pH ≥ 5, then pass 2BV5% sodium hydroxide solution into the anion exchange column at 0.5BV / h, wash with water until pH≤9, that is, anion The exchange resin regeneration is complete.

Embodiment 2

[0024] Alcohol in the alcohol-alkali solution of this embodiment is an example of ethanol solution.

[0025] Under the temperature condition of 25°C, use the wet method to pack the column, put 100ml of the anion exchange resin to be regenerated into the glass chromatography column, the diameter-to-height ratio is 1:4, and pass 2.5BV alcohol-alkali solution at a flow rate of 0.4BV / h Anion exchange resin, the concentration of sodium hydroxide in alcohol-alkali solution is 4%, the concentration of ethanol is 75%, washed with water until pH≤9. Then, pass through 2.5BV4% hydrochloric acid solution at 0.4BV / h, wash with water until pH ≥ 5, then pass 2.5BV4% sodium hydroxide solution into the anion exchange column at 0.4BV / h, wash with water until pH≤9, That is, the regeneration of the anion exchange resin is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com