Aniline post processing system and method

A technology of aniline and nitrobenzene, which is applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of blockage of heat exchangers by dust and other problems, and achieve the effect of improving the time of continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

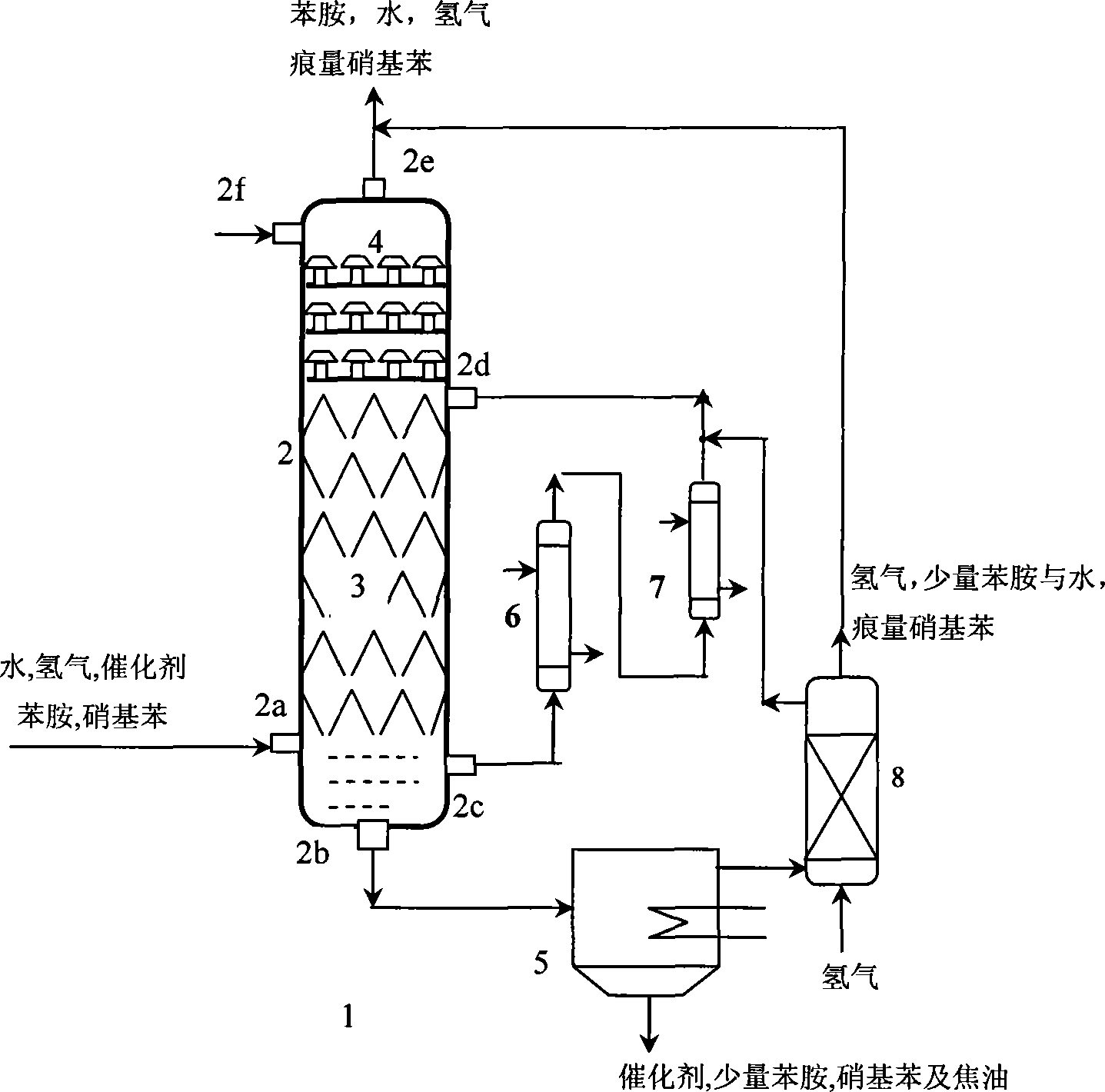

[0052] The cylinder wall of the device (2), the multi-layer inclined baffle area (3), the floating valve structure area (4) and the nozzles (2a-2f) are successively connected to form a complete catalyst dust treatment and aniline reduction process. Apparatus for nitrobenzene content (2). Wherein the heights of the multi-layer oblique baffle area (3) and the floating valve structure area (4) are respectively 1 time and 5 times the diameter of the device (2). Connect the bottom inlet (2a) of the device (2) with pipes. Each nozzle of the device (2) is connected with equipment such as heat exchangers (6, 7) and settling tank (5) one by one with pipelines to form a complete aniline post-treatment system (1).

[0053] The bottom of the tower of the device (2) is first poured into aniline (60° C.) with a certain liquid level height (0.5 times of the diameter of the device). The superheated gas (190 ℃, 0.2MPa (absolute pressure), the volume fraction of hydrogen, water and aniline ar...

Embodiment 2

[0058] The cylinder wall of the device (2), the multi-layer inclined baffle area (3), the floating valve structure area (4) and the nozzles (2a-2f) are successively connected to form a complete catalyst dust treatment and aniline reduction process. Apparatus for nitrobenzene content (2). Wherein the heights of the multi-layer oblique baffle area (3) and the floating valve structure area (4) are respectively 0.5 times and 5 times the diameter of the device (2). Connect the bottom inlet (2a) of the device (2) with pipes. Each nozzle of the device (2) is connected with equipment such as heat exchangers (6, 7) and settling tank (5) one by one with pipelines to form a complete aniline post-treatment system (1).

[0059] The bottom of the device (2) is first filled with aniline (40° C.) at a certain liquid level (1 times the diameter of the device). Superheated gas (200°C, 0.135MPa (absolute pressure), volume fraction of hydrogen, water and aniline were 72%, 18%, 9%, other substan...

Embodiment 3

[0064] The cylinder wall of the device (2), the multi-layer inclined baffle area (3), the floating valve structure area (4) and the nozzles (2a-2f) are successively connected to form a complete catalyst dust treatment and aniline reduction process. Apparatus for nitrobenzene content (2). Wherein the heights of the multi-layer oblique baffle area (3) and the floating valve structure area (4) are respectively 10 times and 5 times the diameter of the device (2). Connect the bottom inlet (2a) of the device (2) with pipes. Each nozzle of the device (2) is connected with equipment such as heat exchangers (6, 7) and settling tank (5) one by one with pipelines to form a complete aniline post-treatment system (1).

[0065] The bottom of the device (2) is first filled with aniline (40° C.) at a certain liquid level (1.5 times the diameter of the device). The superheated gas (240 ℃, 2MPa (absolute pressure), the volume fraction of hydrogen, water and aniline are 51%, 32%, 16% respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com