Device and method for extracting uranium from uranium-containing wastewater or seawater and application thereof

A wastewater and seawater technology, applied in the field of uranium extraction devices, can solve the problems of tedious and time-consuming, secondary pollution, increased operation procedures and costs, and achieve the effects of simplifying operation difficulty, long regeneration period and saving extraction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

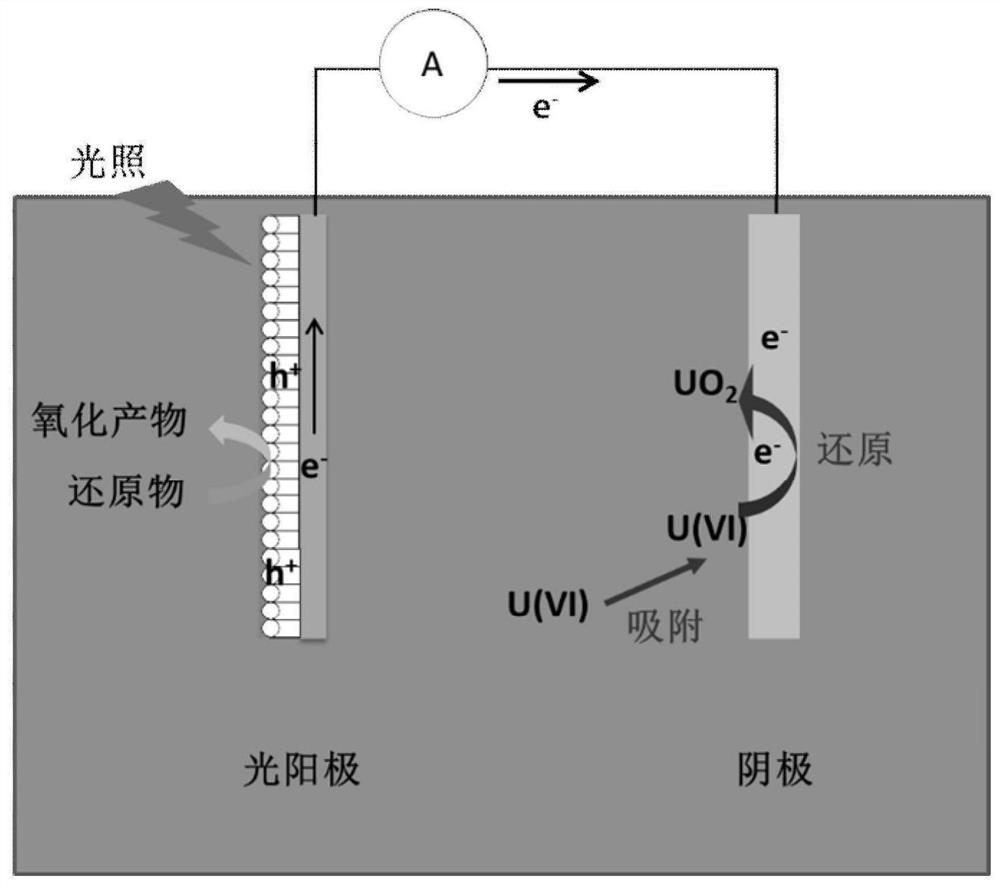

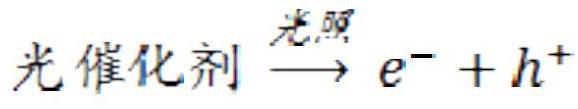

[0037] The invention provides a method for preparing a photocatalytic fuel cell for extracting uranium from uranium-containing wastewater or seawater, comprising the following steps:

[0038] (1) uniformly coating or fixing the photocatalytic material on the surface of the anode; obtaining a photoanode loaded with photocatalyst;

[0039] (2) The photoanode of the loaded photocatalyst obtained in step (1) is used as the anode, and the cathode reaction sheet is used as the cathode, and is connected with a wire between the anode and the cathode; after the anode, the cathode and the wire are connected, place Photocatalytic fuel cells are formed in uranium-containing wastewater or seawater, or placed in uranium-containing wastewater or seawater in a reactor.

[0040] The invention provides a method for extracting uranium from uranium-containing wastewater or seawater, which includes the following steps: adding the device into uranium-containing wastewater or seawater or reactor ura...

Embodiment 1

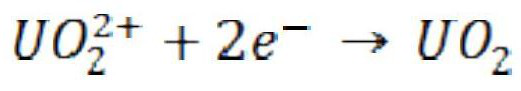

[0043] This example simulates the extraction of uranium from uranium-containing wastewater. The titanium dioxide nanotube array is used as the photoanode, the size is 2cm*3.5cm, the white titanium mesh is used as the cathode, the size is 3cm*3.5cm, and the quartz dish is used as the reaction vessel. It is 5cm*5cm*5cm; because uranium in uranium-containing wastewater and seawater is usually expressed as UO 2 2+ exists, so add UO to deionized water 2 (NO 3 ) 2 Formed containing 6mg / L UO 2 2+ The test liquid is used to simulate uranium-containing wastewater.

[0044] Adjust the pH value of the experimental liquid to 7 by adding 0.1mol / L HCl or NaOH to the experimental liquid;

[0045] Pour 80ml of the prepared experimental liquid into a quartz vessel, stir continuously at room temperature and use a 1KW xenon lamp as a light source to irradiate the photoanode, and react for 2.5h;

[0046] UO in test liquid after detection test 2 2+ The concentration is 3.75 mg / L, and 0.18...

Embodiment 2

[0048] Example 2. This example is used to simulate the extraction of uranium from seawater. In Example 1, other conditions remain unchanged, and UO is added to deionized water. 2 (NO 3 ) 2 Formed with NaCl containing 6mg / L UO 2 2+ and 32g / LNaCl test liquid; after 2.5h of light, the remaining UO in the reaction solution was measured 2 2+ The concentration is 2.808mg / L, and the amount of uranium extracted by the photocatalytic fuel cell from the simulated wastewater is 0.26mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com