Diesel engine particle catcher

A particle trap and particle trap technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of frequent regeneration, increased vehicle cost, failure, etc., to facilitate regeneration and maintenance, improve utilization efficiency, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific content of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

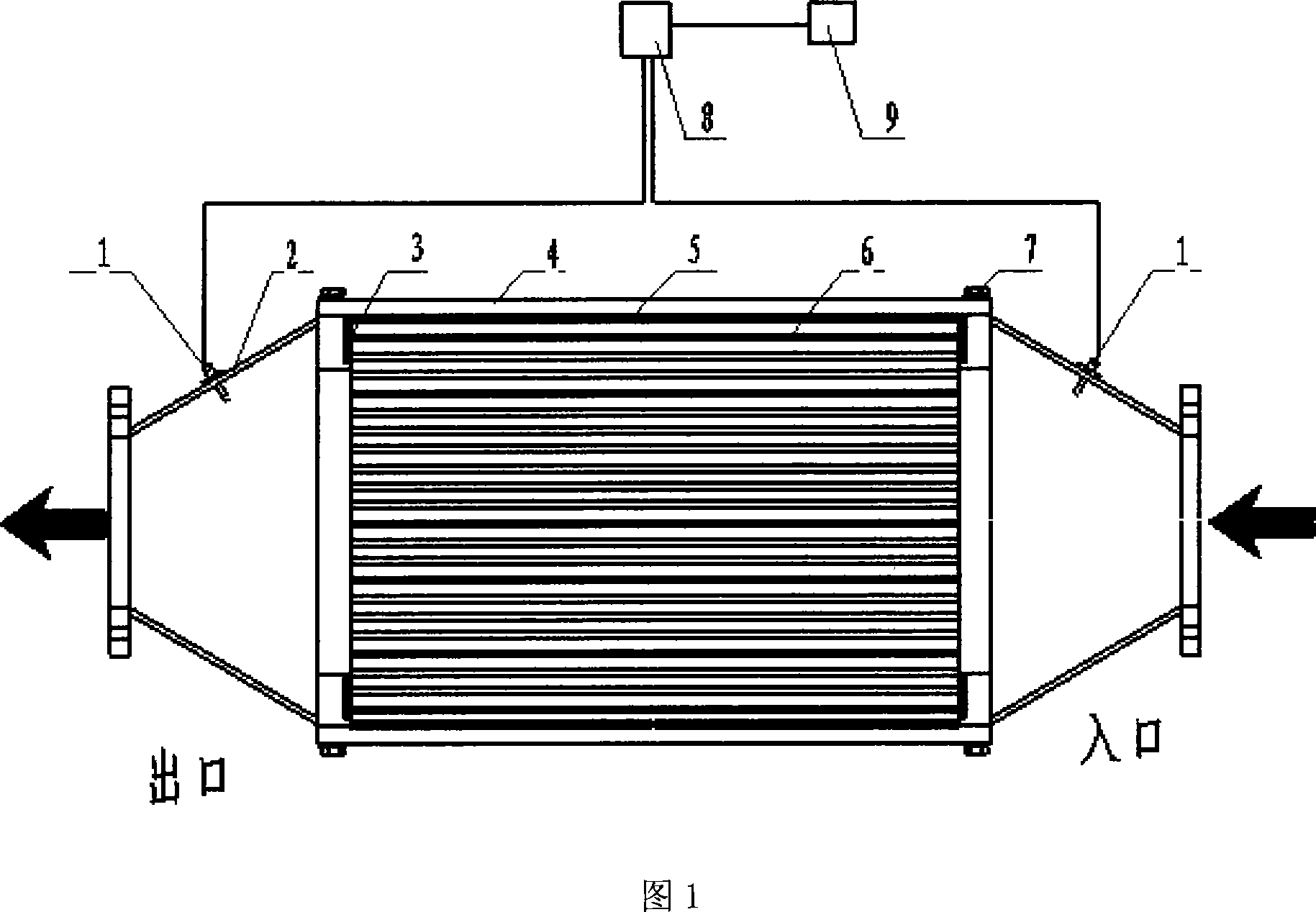

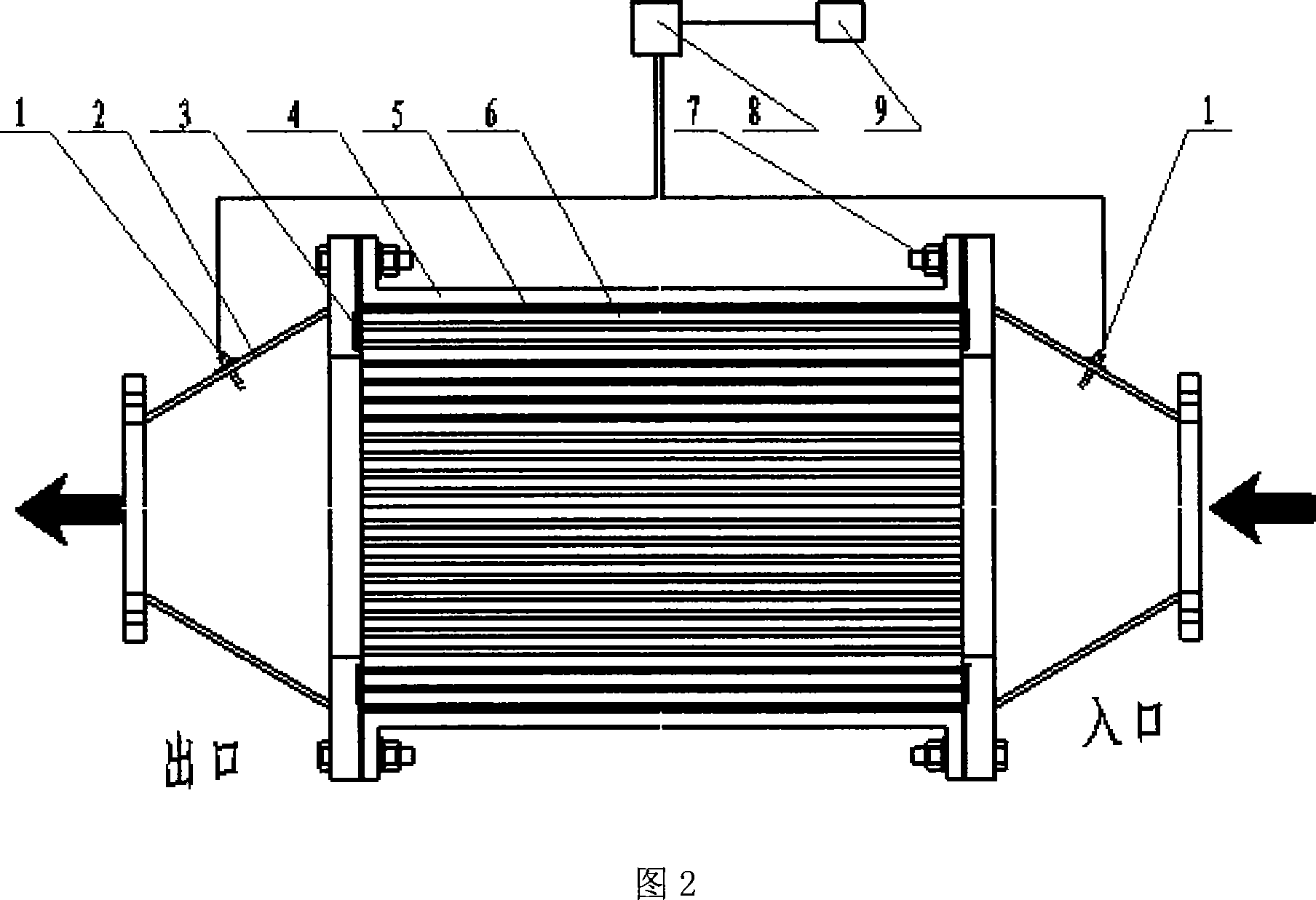

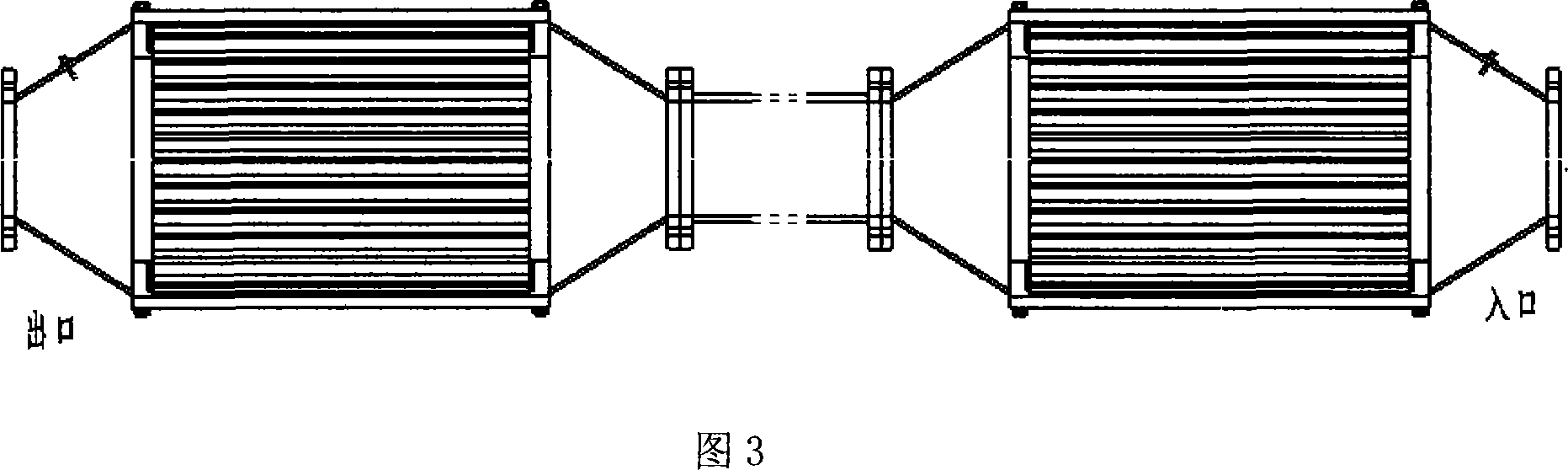

[0020] Fig. 1 is a schematic diagram of a single structure of a square graded filtration, detachable, off-vehicle cycle regeneration diesel engine particulate filter. The exhaust gas of the diesel engine enters the particulate filter from the inlet, and the filter element 6 filters and captures the particulates in the exhaust gas. 5. It is used to prevent the leakage of exhaust gas, and at the same time, it can start the function of shock absorption. During the installation process, the pressure plate 4 in the middle of the shell is pre-tightened and anti-loosening, which can avoid the leakage between the pressure plate and the filler due to poor fit. phenomenon, the positioning surface 3 is used on the housing to prevent exhaust gas leakage caused by the movement of the filter element 6, the pressure sensor 1 collects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com