Mesoporous molecular sieve catalyst for alkane catalytic dehydrogenation and preparing method and application thereof

A mesoporous molecular sieve and catalytic dehydrogenation technology, applied in the field of mesoporous molecular sieve catalyst and its preparation, can solve the problems of limited extension of catalyst regeneration period, high investment and operation cost, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

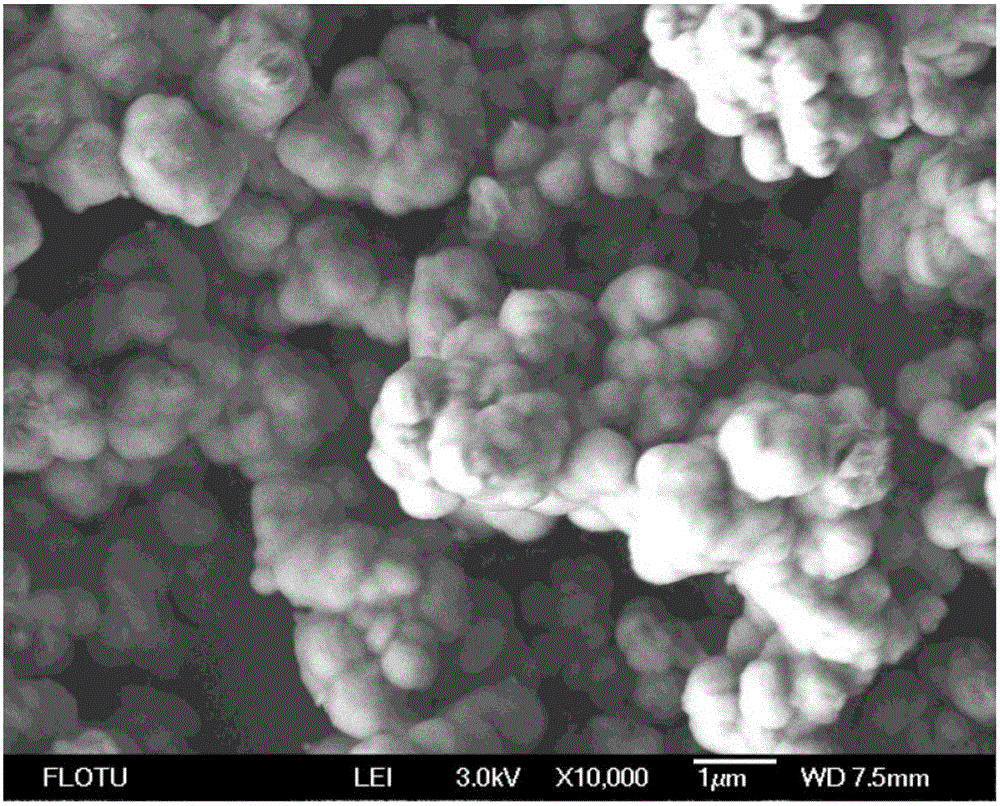

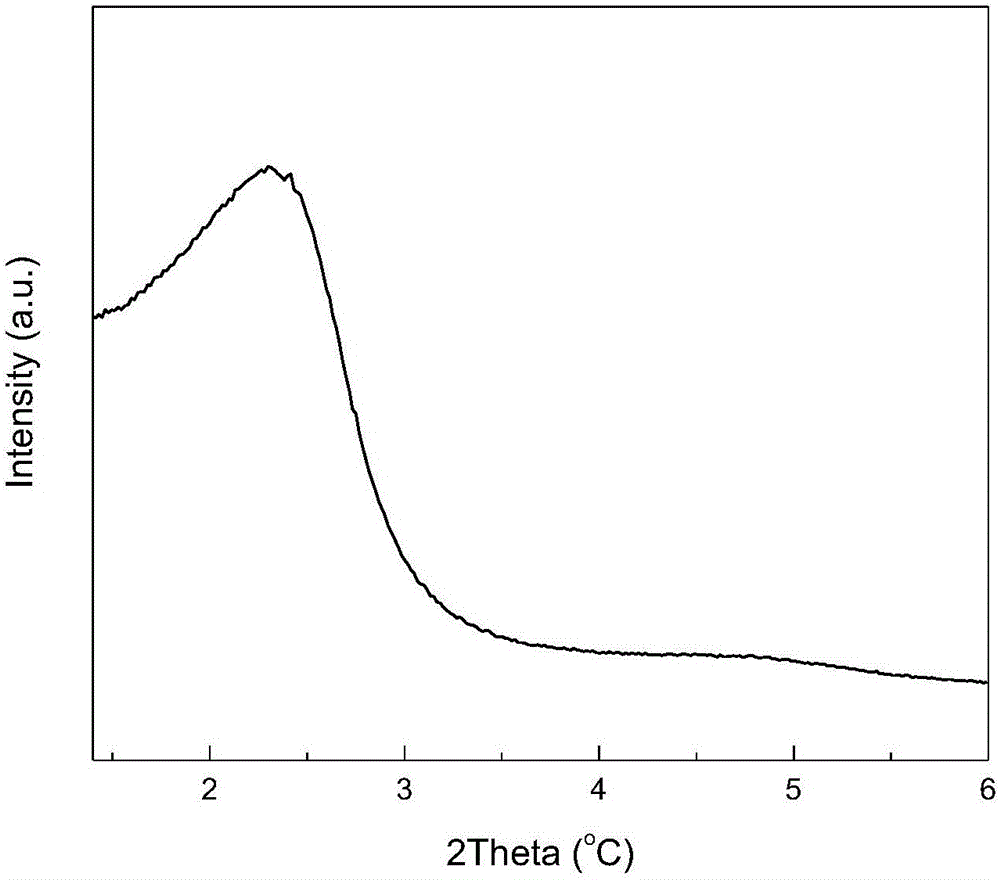

Embodiment 1

[0022] At room temperature, 6g of dodecylamine (DDA) was added to 41.04g of ethanol (EtOH), stirred to dissolve it completely, and then 58.32g of water (H 2 O) continue to stir until clear solution is obtained; Weigh 0.57g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) Dissolve in 8.72g of ethanol, mix with 25g of tetraethyl orthosilicate (TEOS) after complete dissolution; add the mixed solution dropwise into the solution consisting of ethanol, water and dodecylamine. After continuing to stir for 24 hours, filter with suction, wash, dry at 120°C for 3 hours, and roast at 550°C for 5 hours. Before the reaction, it was reduced in a hydrogen flow at 600°C for 1 hour. The catalyst evaluation results showed that the conversion rate of propane was 39.88wt%, the yield of propylene was 34.16wt%, and the selectivity of propylene was 85.65wt%.

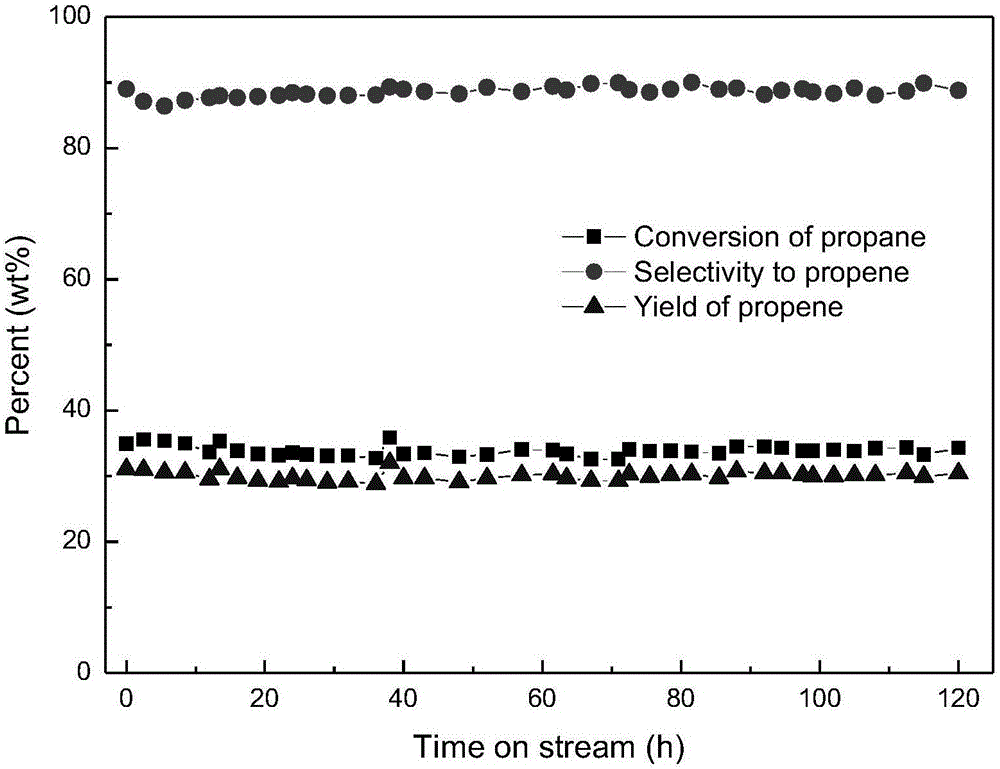

Embodiment 2

[0024] At room temperature, 5.56g of dodecylamine (DDA) was added to 45.6g of ethanol (EtOH), stirred to make it dissolve completely, and then 72g of water (H 2 O) continue to stir until clear solution is obtained; Weigh 1.64g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) and 1.27g stannous chloride (SnCl 2 2H 2 O) Dissolve in 9.68g of ethanol, mix with 20.83g of tetraethyl orthosilicate (TEOS) after complete dissolution; add the mixed solution dropwise to the solution consisting of ethanol, water and dodecylamine. After continuing to stir for 48 hours, filter with suction, wash, dry at 100°C for 5 hours, and roast at 550°C for 3 hours. Before the reaction, it was reduced in a hydrogen flow at 550°C for 1 hour. The catalyst evaluation results showed that the conversion rate of propane was 36.43wt%, the yield of propylene was 32.47wt%, and the selectivity of propylene was 89.13wt%.

Embodiment 3

[0026] At room temperature, 4.67g of dodecylamine (DDA) was added in 34.2g of ethanol (EtOH), stirred to make it dissolve completely, then added 48.6g of water (H 2 O) continue to stir until clear solution is obtained; Weigh 0.55g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) Dissolve in 7.26g of ethanol, mix with 18.75g of tetraethyl orthosilicate (TEOS) after complete dissolution; add the mixed solution dropwise to the solution consisting of ethanol, water and dodecylamine. After continuing to stir for 30h, filter with suction, wash, dry at 100°C for 12h, and roast at 600°C for 5h. Before the reaction, it was reduced in a hydrogen flow at 550°C for 2 hours. The catalyst evaluation results showed that the conversion rate of propane was 39.04wt%, the yield of propylene was 33.89wt%, and the selectivity of propylene was 86.80wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com