Hydrofining catalyst and preparation method thereof

A hydrofining and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. High active temperature and other problems, to achieve the effect of preventing grain fusion and growth, improving heat resistance, and low active temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

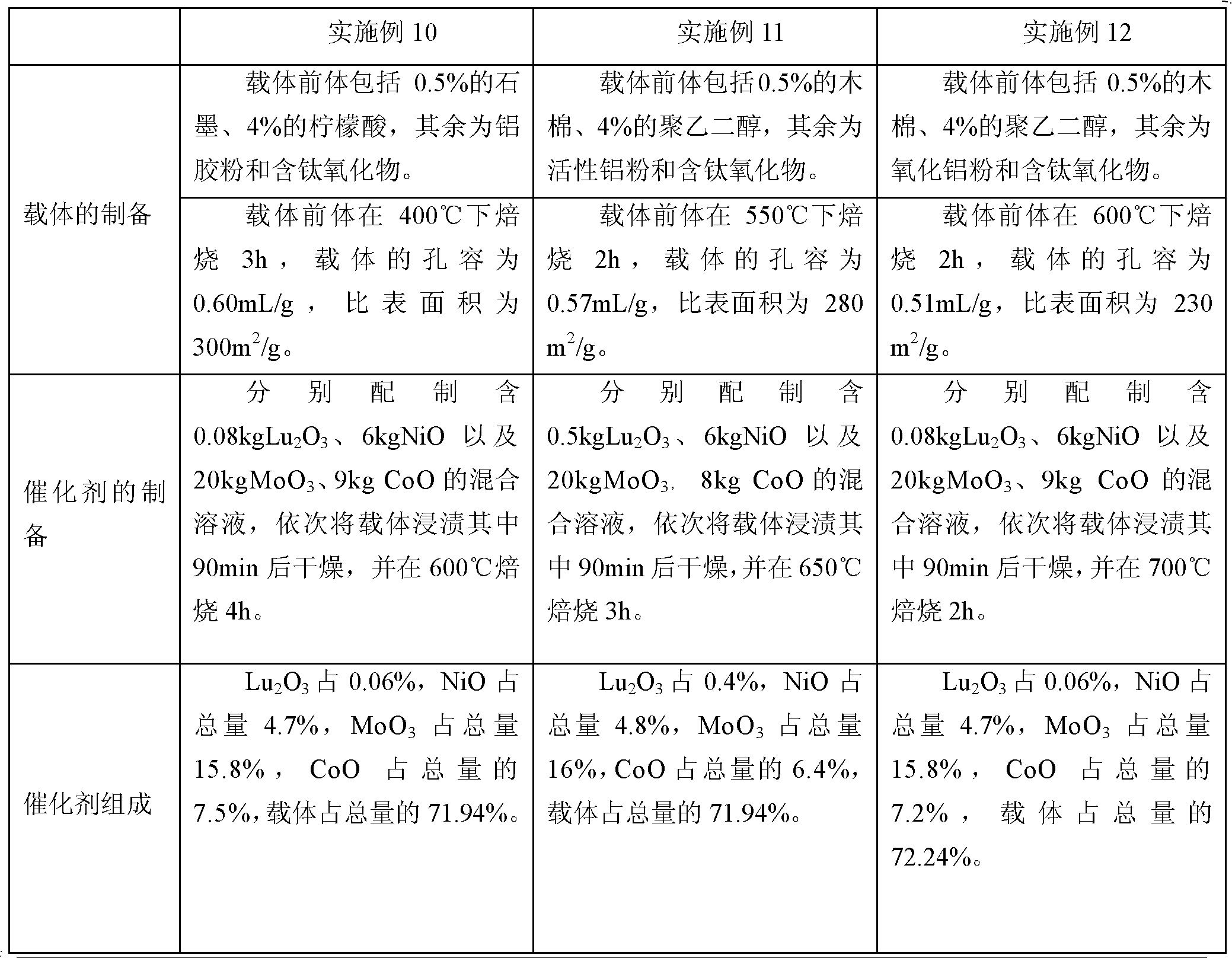

Embodiment 1

[0027] A hydrorefining catalyst is prepared through the following steps:

[0028] Preparation of the carrier: 72.0kg of modified alumina powder prepared by carbonization, 24.0kg of metatitanic acid, and 1.5kg of hydroxycellulose were mixed and ball-milled to more than 200 mesh, and an appropriate amount of water and 4.0kg of phosphoric acid with a concentration of 52% were added and kneaded. squeeze into clover strips. Drying at 110-120° C. for 3 hours to obtain a carrier precursor. Based on the total amount of the carrier precursor as 100%, hydroxycellulose accounts for 1.5%, phosphoric acid accounts for 2.1%, and the rest is modified alumina powder and titanium-containing oxide prepared by carbonization.

[0029] Then the carrier precursor was calcined at 570° C. for 3 hours to obtain 90.5 kg of carrier. Among them, titanium-containing oxides (TiO 2 ) accounted for 21.7% of the total weight, and γ-alumina accounted for 78.3% of the total weight. The pore volume of the ca...

Embodiment 2

[0033] A hydrorefining catalyst is prepared through the following steps:

[0034] Preparation of the carrier: Mix 72.0kg of modified alumina powder prepared by carbonization, 24.0kg of metatitanic acid, and 4.0kg of scallop powder to a size above 200 mesh, add an appropriate amount of water and 8.0kg of phosphoric acid with a concentration of 52%, knead, squeeze into clover strips. Dry at 110-120° C. for 1 hour to obtain a carrier precursor. Based on 100% of the total weight of the carrier precursor, safflower powder accounts for 3.8%, phosphoric acid accounts for 4%, and the rest is modified alumina powder and titanium-containing oxide prepared by carbonization. .

[0035] The carrier precursor was calcined at 600°C for 3 h to obtain 91.5 kg of titanium-modified γ-alumina carrier, in which titanium oxide (TiO 2 ) accounted for 21.4% of the total weight, and γ-alumina accounted for 78.6% of the total weight. The pore volume of the carrier is 0.45mL / g, and the specific su...

Embodiment 3

[0039] A hydrorefining catalyst is prepared through the following steps:

[0040] Preparation of the carrier: Mix 72.0kg of modified alumina powder prepared by carbonization, 24.0kg of metatitanic acid, and 0.5kg of scallop powder to a size above 200 mesh, add an appropriate amount of water and 5.0kg of nitric acid with a concentration of 65%, knead, squeeze into clover strips. Drying at 110-120° C. for 3 hours to obtain a carrier precursor. Based on the total amount of the carrier precursor as 100%, the scallop powder accounts for 0.5%, nitric acid accounts for 3.3%, and the rest is modified alumina powder and titanium-containing oxide prepared by carbonization.

[0041] Then the carrier precursor was calcined at 570° C. for 3 hours to obtain 90.5 kg of carrier. Among them, titanium-containing oxides (TiO 2 ) accounted for 21.7% of the total weight, and γ-alumina accounted for 78.3% of the total weight. The pore volume of the carrier is 0.55mL / g, and the specific surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com