Selective hydrogenation catalyst for producing biodiesel and preparation method and application of selective hydrogenation catalyst

A hydrogenation catalyst and biodiesel technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low selectivity, low isomerization, high reaction temperature, etc., to achieve reduced agglomeration, excellent Thermal conductivity, the effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

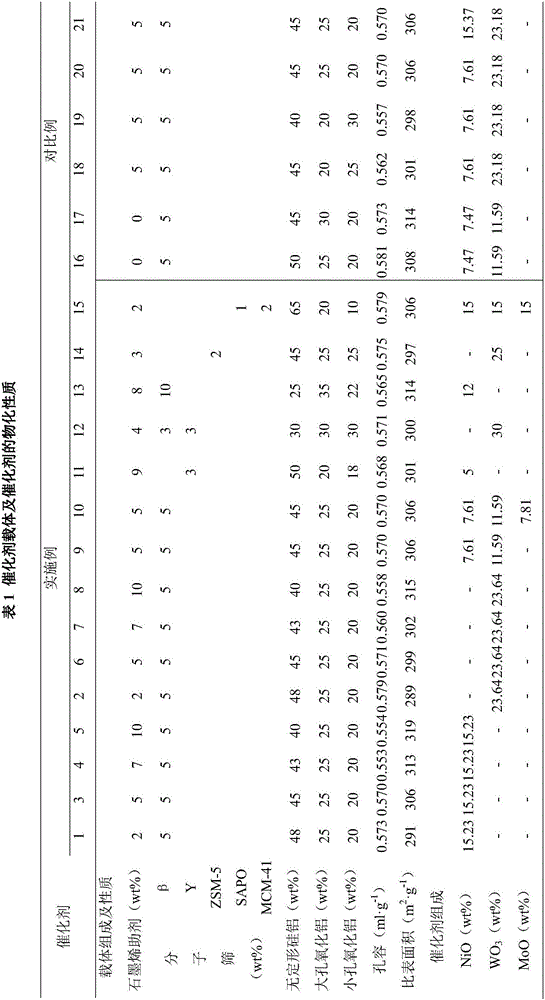

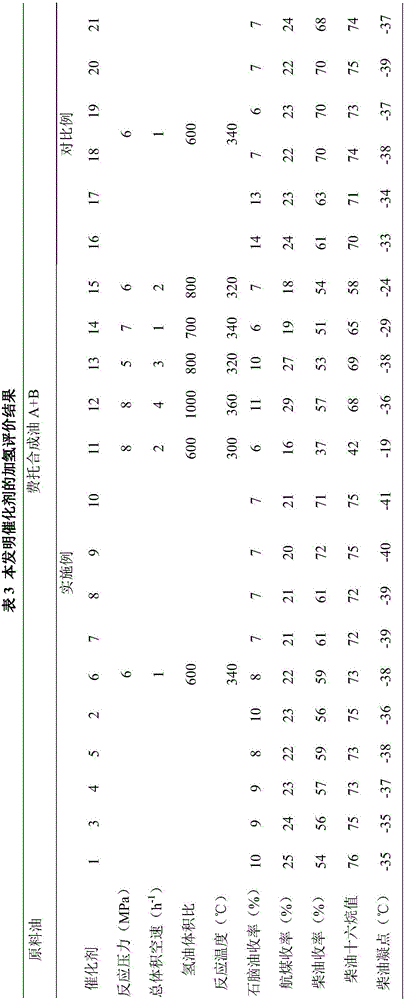

Examples

preparation example Construction

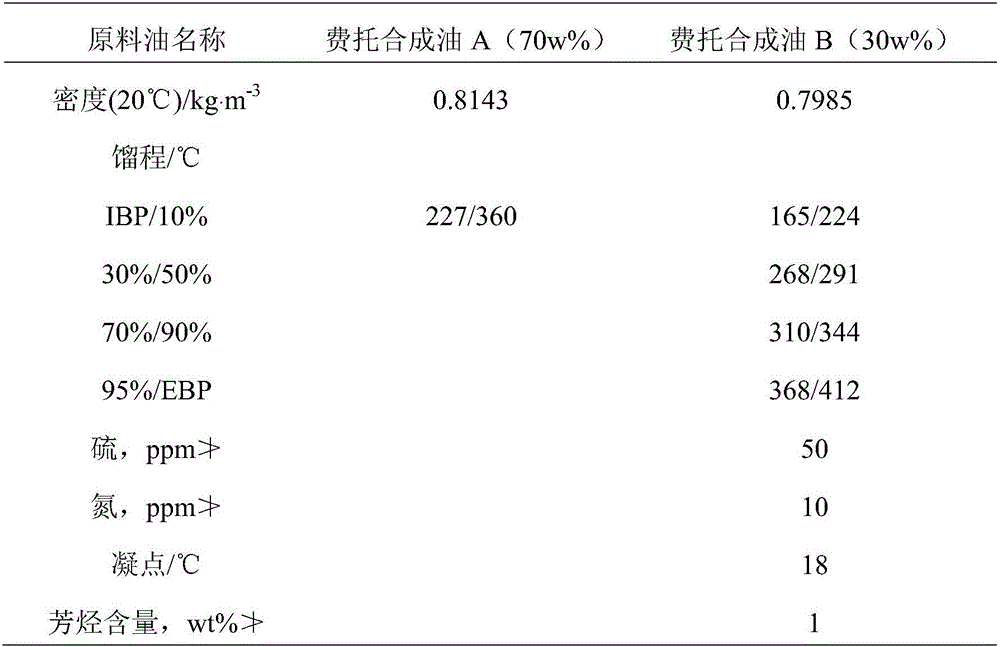

[0058] Raw material preparation and purchase

[0059] 1, the preparation method of graphite oxide, concrete steps are as follows:

[0060] 1) Weigh 1g of natural graphite and 1g of anhydrous NaNO 3 Slowly put in 50ml concentrated H in an ice bath 2 SO 4 In, with 6gKMnO 4 Slowly add the oxidizing agent for oxidation treatment for 0.5h (stir continuously during the period), this is the pre-oxidation stage;

[0061] 2) Put the flask in a 35°C water bath and stir for 2 hours, then slowly add 200ml of deionized water, during which the temperature should not exceed 50°C, then transfer to a 98°C water bath and continue to stir for 30 minutes at high temperature. Dilute to 400ml, slowly add 30ml of H 2 o 2 (mass fraction is 30%), filtered while hot, fully centrifuged and washed with 5% HCl, until there is no SO in the filtrate 4 2- , and then centrifuged and washed several times with deionized water to remove Cl - , until the solution becomes neutral;

[0062] 3) Transfer th...

Embodiment 1

[0074] The preparation method of graphene additive 1, concrete steps are as follows:

[0075] 1) Weigh 1 g of the graphite oxide prepared above and add it to 1 L of deionized water, and ultrasonicate it at 180 W at 40°C for 2 hours. After the ultrasonication is over, add 20 mL of 0.1 mol / L Ni(NO 3 ) 2 ·6H 2 O solution, stirred at room temperature for 10h to obtain a mixed solution;

[0076] 2) Add 4 g of citric acid to the mixed solution, and conduct a hydrothermal reaction at a temperature of 180° C. for 6 hours. After the reaction solution is cooled, the solution is first centrifuged and washed twice with ethanol, and then centrifuged and washed several times. completely remove NO 3 - . The substance obtained by centrifugation was freeze-dried in a freeze dryer for 20 hours, and the graphene additive 1 was obtained after grinding.

[0077] The preparation method of carrier 1, the specific steps are as follows:

[0078] 1) Take 0.2g of graphene additive 1, 0.5g of β mo...

Embodiment 2

[0084] The preparation method of graphene additive 2, concrete steps are as follows:

[0085] 1) First weigh 1 g of graphite oxide and add it to 1 L of deionized water, and then ultrasonicate it at 180 W at 40°C for 2 hours. After the ultrasonication is over, add 10 mL of 0.1 mol / L (NH 4 ) 6 h 2 W 12 o 40 (ammonium metatungstate) solution, stirred at room temperature for 10h to obtain a mixed solution;

[0086] 2) Add 4 g of citric acid to the mixed solution, and conduct a hydrothermal reaction at a temperature of 180° C. for 6 hours. After the reaction solution is cooled, the solution is first centrifuged and washed twice with ethanol, and then centrifuged and washed several times. , complete removal of NH 4 + . Freeze-dry the centrifuged substance in a freeze dryer for 20 hours, and then grind to obtain graphene additive 2;

[0087] The preparation method of carrier 2, the specific steps are as follows:

[0088] 1) Weigh 0.2g of graphene auxiliary agent 2, 0.5g of β m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com