Thin-layer MCM-22 molecular sieve microsphere with microporous/mesoporous structure as well as preparation and application of thin-layer MCM-22 molecular sieve microsphere

A mesoporous structure and molecular sieve technology, applied in the chemical industry, can solve the problems of poor hydrothermal stability of single-layer MWW molecular sieves, difficulty in controlling product crystal phase, cumbersome operation process, etc., to achieve optimized synthesis system and preparation process, high selectivity, The effect of avoiding cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

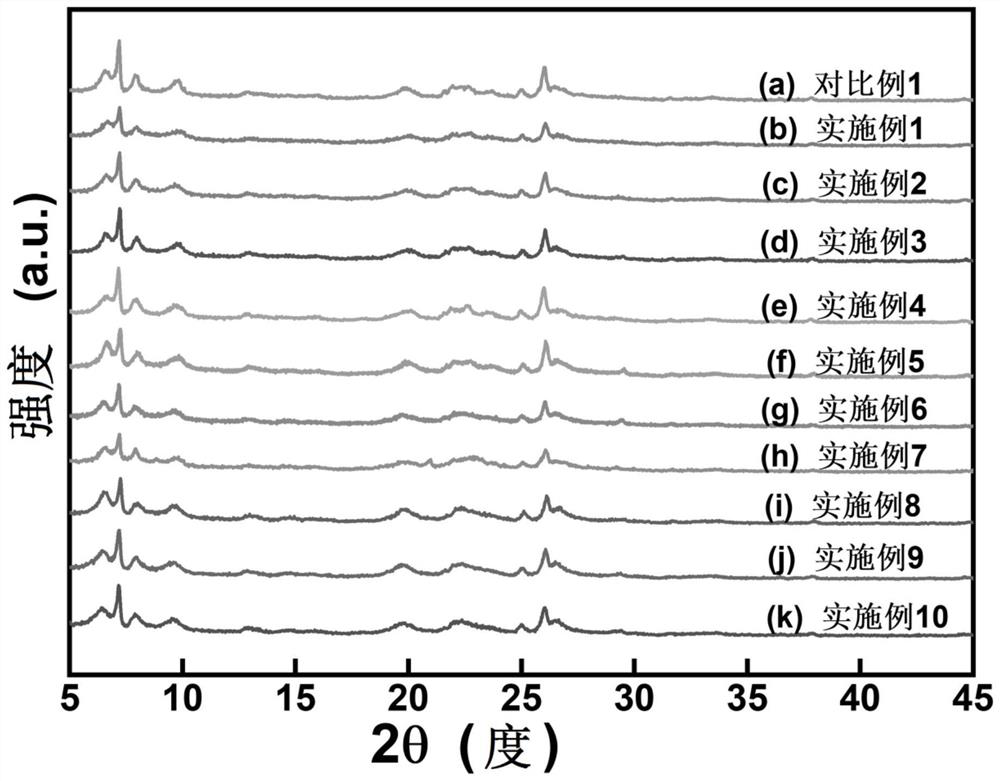

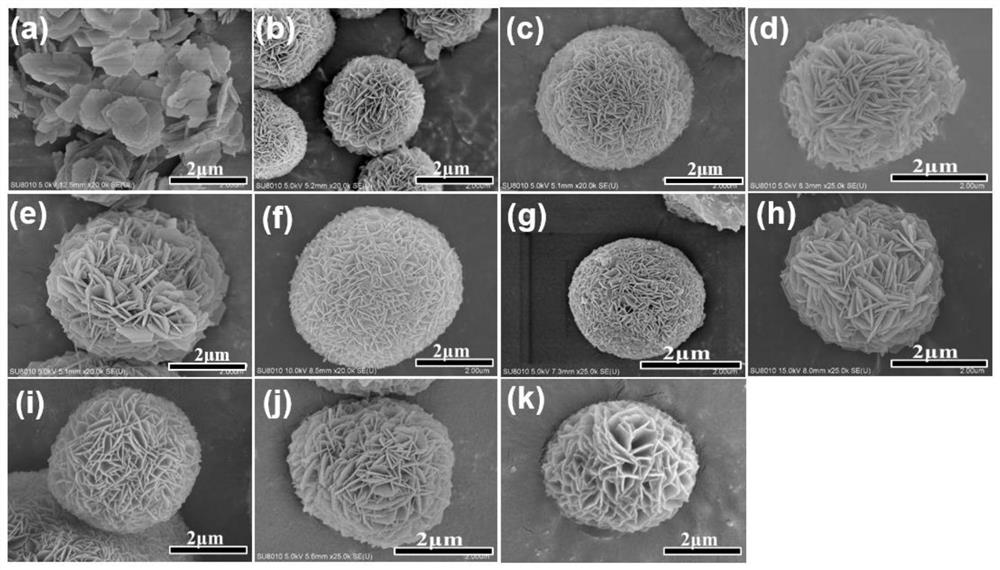

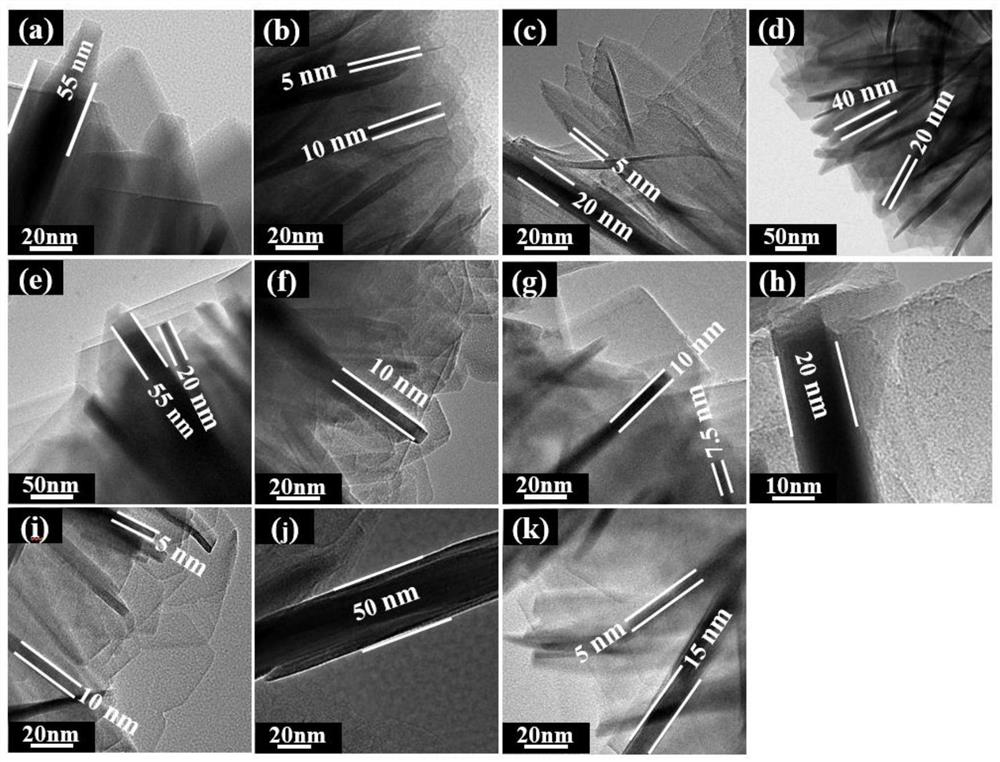

Embodiment 1

[0078] Add main template agent HMI (R to 20g deionized water 1 ) and the second templating agent Cl-C 4-6-4 (R 2 ) to make liquid A; NaAlO 2 , NaOH, dissolved in a certain amount of 40g deionized water, and configured as B solution. Slowly add liquid A dropwise into liquid B and stir, add silica sol, and age at 60°C for 5 hours to obtain a mixed gel. The molar ratio of the mixed gel is: SiO 2 / Al 2 o 3 =30,OH - / SiO 2 =0.2,H 2 O / SiO 2 =30,R 1 / SiO 2 =0.2, R 2 / SiO 2 = 0.02. Move the mixed rubber into a crystallization kettle, place it in a rotary oven, set the rotation speed at 60r / min, and conduct hydrothermal crystallization at 150°C for 7d. Then by washing, separating and drying, the MCM-22 microsphere molecular sieve is obtained. The XRD pattern of the synthesized catalyst, such as figure 1 As shown in b, it is a pure phase MCM-22 molecular sieve. SEM image, such as figure 2 As shown in b, the particle size of MCM-22 microspheres is 2 μm. TEM images, su...

Embodiment 2

[0080] Add main template agent HMI (R to 20g deionized water 1 ) and the second templating agent Br-C 6-6-6 (R 2 ) to make liquid A; NaAlO 2 , KOH, dissolved in 34g deionized water, and configured as liquid B. Add liquid A dropwise to liquid B and stir, add coarse-pore silica gel, and age at 60°C for 5 hours to obtain a mixed gel. The molar ratio of the mixed gel is: SiO 2 / Al 2 o 3 =35,OH - / SiO 2 =0.15,H 2 O / SiO 2 =27,R 1 / SiO 2 =0.2, R 2 / SiO 2 = 0.015. Move the mixed rubber into a crystallization kettle, place it in a rotary oven, set the rotation speed at 60r / min, and conduct hydrothermal crystallization at 150°C for 7d. Then by washing, separating and drying, the MCM-22 microsphere molecular sieve is obtained. The XRD pattern of the synthesized catalyst, such as figure 1 As shown in c, it is a pure phase MCM-22 molecular sieve. SEM image, such as figure 2 As shown in c, the particle size of MCM-22 microspheres is 2 μm. TEM images, such as image 3 As...

Embodiment 3

[0082] Add main template agent HMI (R to 20g deionized water 1 ) and the second templating agent HO-C 8-6-8 (R 2 ) to prepare liquid A; dissolve aluminum nitrate, NaOH, and 30 g of deionized water to prepare liquid B. Add liquid A dropwise to liquid B and stir, add silica gel, and age at 60°C for 5 hours to obtain a mixed gel. The molar ratio of the mixed gel is: SiO 2 / Al 2 o 3 =30,OH - / SiO 2 =0.25,H 2 O / SiO 2 =25,R 1 / SiO 2 =0.2, R 2 / SiO 2 = 0.02. Move the mixed rubber into a crystallization kettle, place it in a rotary oven, set the rotation speed at 60r / min, and conduct hydrothermal crystallization at 150°C for 7d. Then by washing, separating and drying, the three-dimensional MCM-22 microsphere molecular sieve is obtained. The XRD pattern of the synthesized catalyst, such as figure 1 As shown in d, it is a pure phase MCM-22 molecular sieve. SEM image, such as figure 2 As shown in d, the particle size of MCM-22 microspheres is 2 μm. TEM images, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com