Method for preparing nano molecular sieve by coordinating amino acid assisting and sectional crystallizing through concentrated gel system

A technology of nano-molecular sieve and segmental crystallization, which is applied in chemical instruments and methods, molecular sieves and alkali-exchange compounds, nanotechnology for materials and surface science, etc., can solve problems of low crystallinity, complex and changeable control factors, poor Dispersion and other issues, to achieve good crystallization, improve safety and reliability, and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

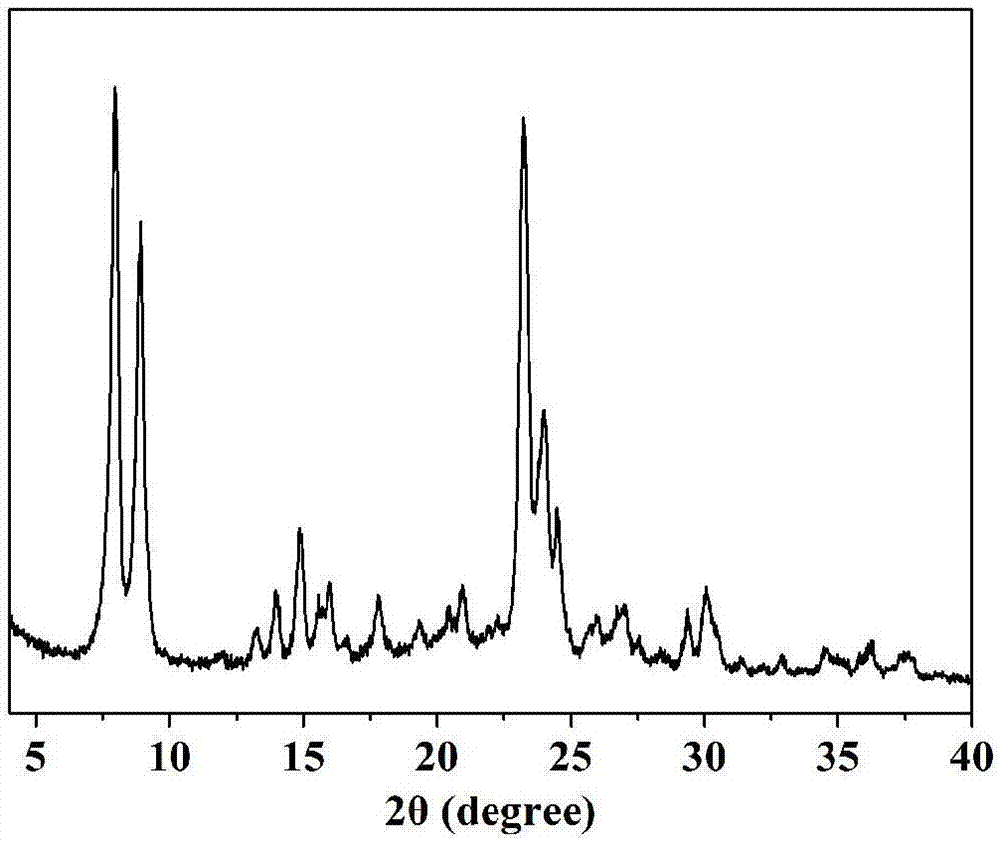

[0036] This example presents nano-Silicalite-1 molecular sieves. Under the concentrated gel system, the method of synergistically preparing nano-molecular sieves through amino acid assistance and segmented crystallization is adopted:

[0037] Disperse 1.819g ethyl orthosilicate and 3.197g tetrapropylammonium hydroxide aqueous solution (the mass fraction of tetrapropylammonium hydroxide solute is 25%) in 3g deionized water, and stir evenly at room temperature for 3 hours until the orthosilicic acid Ethyl ester is completely hydrolyzed; then add 0.13g lysine, stir for 10min to disperse evenly, then follow the molar ratio of 9H 2 O: 1SiO 2 The excess water was evaporated under an infrared oven lamp to obtain a transparent initial gel of Silicalite-1, which was placed in a stainless steel reactor with a polytetrafluoroethylene liner, crystallized in an oven at 60°C for 48 hours, and then moved to Continue to crystallize in an oven at 170°C for 24 hours. After the crystallization ...

Embodiment 2

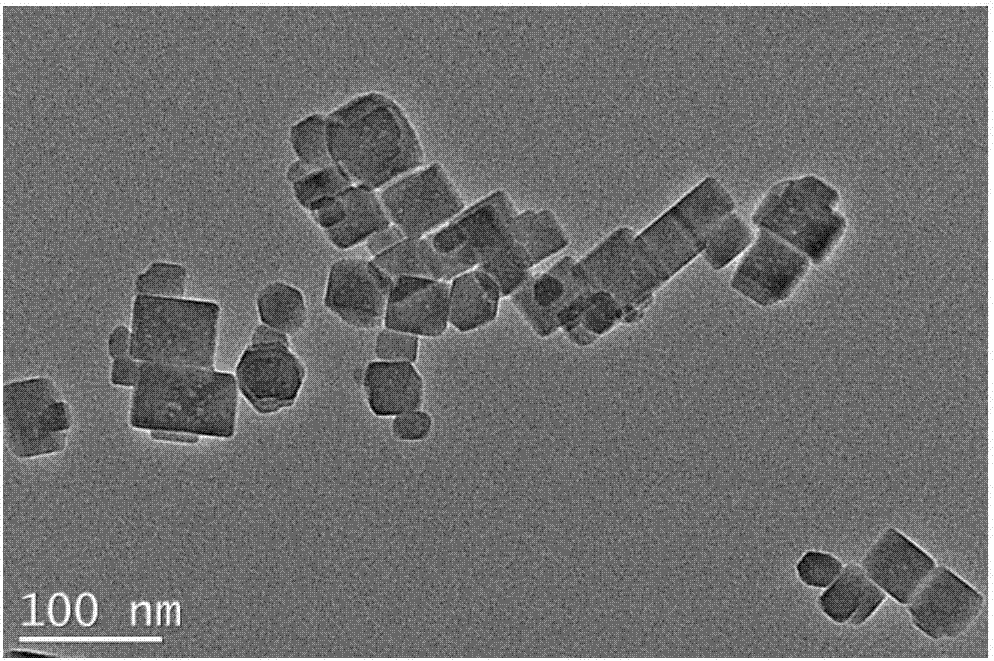

[0043] This example presents nano-Silicalite-1 molecular sieves. Under the concentrated gel system, the method of synergistically preparing nano-molecular sieves through amino acid assistance and segmented crystallization is adopted:

[0044] Disperse 1.819g tetrapropylammonium hydroxide solution and 3.197g tetrapropylammonium hydroxide solution (tetrapropylammonium hydroxide solute mass fraction is 25%) in 3g deionized water, and stir evenly at room temperature for 3 hours to reach tetrapropylammonium hydroxide solution. The ester is completely hydrolyzed; then add 0.13g of lysine, stir for 10min until the dispersion is uniform, then follow the molar ratio of 9H 2 O: 1SiO 2 The excess water was evaporated under an infrared oven lamp to obtain a transparent initial gel of Silicalite-1, which was placed in a stainless steel reactor with a polytetrafluoroethylene liner, crystallized in an oven at 80 °C for 24 hours, and then moved to The crystallization was continued in an oven...

Embodiment 3

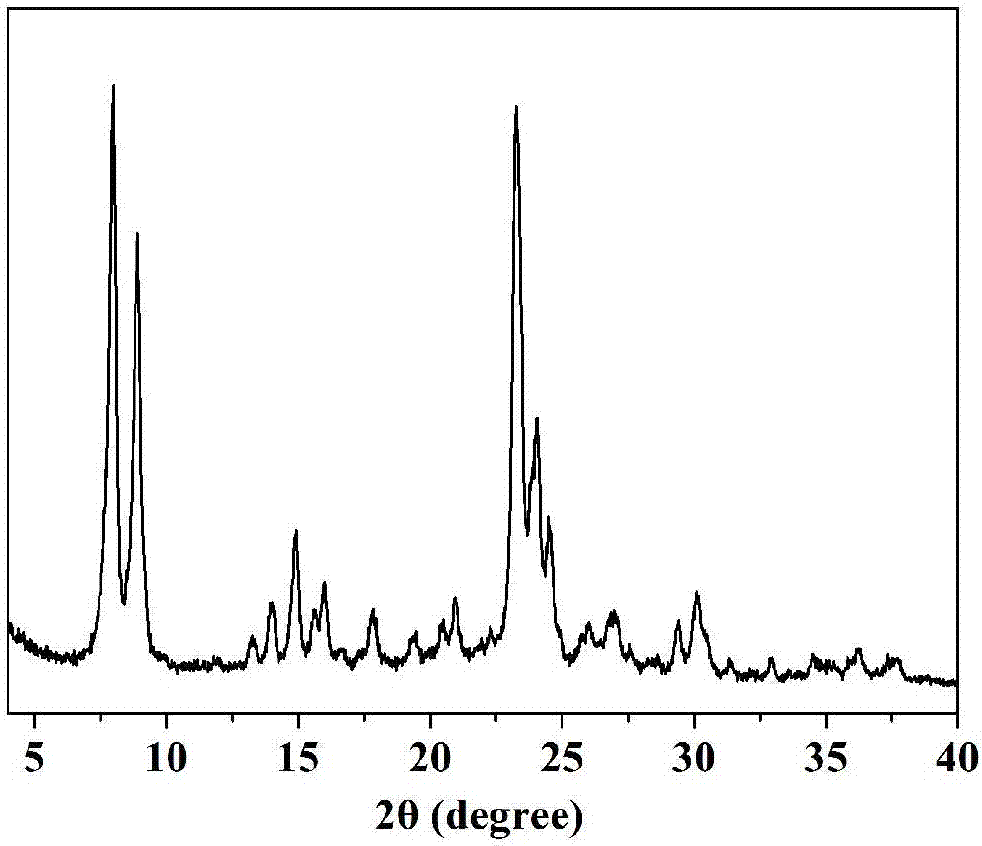

[0049] In this example, nano-beta molecular sieves are given. Under the concentrated gel system, the method of synergistically preparing nano-molecular sieves through amino acid assistance and segmental crystallization is adopted:

[0050] Disperse 1.819g ethyl orthosilicate and 2.78g tetraethylammonium hydroxide (the mass fraction of tetraethylammonium hydroxide is 25%) in 3g of deionized, and stir uniformly at room temperature for 3 hours until the ethyl orthosilicate is completely Hydrolyze to obtain solution A; 0.1g sodium metaaluminate (wherein Al 2 o 3 The content is 0.042g) mixed with 0.01g sodium hydroxide and 1g water and ultrasonically dissolved to obtain solution B; slowly add solution B to solution A, and at the same time add 0.13g lysine to solution A, stir for 2 hours until uniform , according to the molar ratio 6H 2 O: 1SiO 2 The excess water was evaporated and removed under the infrared oven lamp to obtain the initial gel of Beta molecular sieve; it was put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com