Synthesis method of nano small-grain ZSM-22 molecular sieve

A technology for ZSM-22 and synthesis methods, applied in the direction of molecular sieves and base exchange compounds, nanotechnology, chemical instruments and methods, etc., can solve the problems of high production cost and difficulty in industrial application of ZSM-22 molecular sieves, and achieve good application prospects, Improved mass transfer and diffusion performance, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

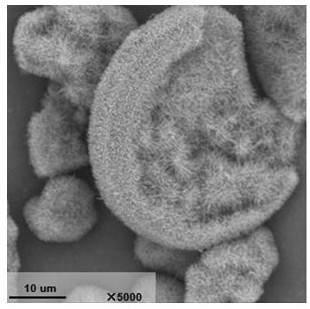

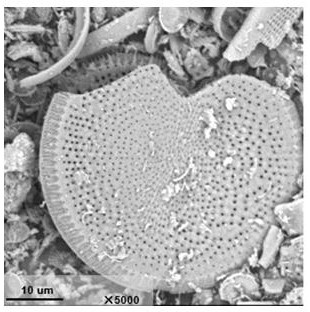

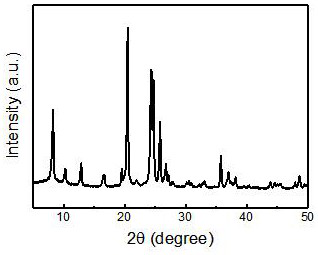

[0032] Example 1: Preparation of small-grain ZSM-22 molecular sieve based on in-situ crystallization of dealuminated diatomite

[0033] Get 2.4 g dealuminated diatomite and mix with 43.8 g deionized water, add 0.54 g KOH, at 50 o After leaching at C for 8 h, separate by suction filtration, and temporarily place the solid phase. Commercial ZSM-22 molecular sieves were added to the liquid phase as seeds, and the amount of seeds added was related to the SiO 2 The mass ratio is 0.1, moved into the water bath 80 o C aging for 8 h. After mixing the solid phase and the aged liquid phase evenly, an initial gel containing seeds is obtained, and its gel composition is 100SiO 2 :Al 2 o 3 :3600H 2 O:20KOH (molar ratio). After stirring for 30 min, it was transferred to a polytetrafluoroethylene-lined reactor for dynamic crystallization at a rate of 400 rpm, and the crystallization temperature was 150 o C, the crystallization time is 42 h. After the crystallization was finished, th...

Embodiment 2

[0035] Example 2: Preparation of small crystal ZSM-22 molecular sieve based on in situ crystallization of dealuminated diatomite. The steps are the same as in Example 1, only some parameters are modulated, as follows:

[0036] Get 2.4 g dealuminated diatomite and mix with 43.8 g deionized water, add 0.27 g KOH, at 30 o After leaching at C for 5 h, separate by suction filtration, and temporarily place the solid phase. Commercial ZSM-22 molecular sieves were added to the liquid phase as seeds, and the amount of seeds added was related to the SiO 2 The mass ratio is 0.02, moved into the water bath 90 o C for 12 h. After mixing the solid phase and the aged liquid phase evenly, an initial gel containing seeds is obtained, and its gel composition is 100SiO 2 :Al 2 o 3 :3600H 2 O:10KOH (molar ratio). After stirring for 30 min, it was transferred to a reaction kettle with a polytetrafluoroethylene liner for dynamic crystallization at a rate of 400 rpm, and the crystallization ...

Embodiment 3

[0038] Example 3: Preparation of ZSM-22 molecular sieve with small crystals based on dealuminated diatomite in situ crystallization under low temperature conditions. The steps are the same as in Example 1, only some parameters are modulated, as follows:

[0039] Adjust the crystallization temperature to 120 o C, the crystallization time is 48 h.

[0040] The synthesized products are ZSM-22 molecular sieves with a particle size width of 50 nm and amorphous silicon source.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com