Attapulgite clay-thiocoumarin functional hybrid material and preparation method and application

A technology of thiocoumarin and hybrid materials, which is applied in the field of heavy metal detection, can solve problems such as poor stability, secondary pollution, and difficulty in recycling, and achieve the effects of improved stability, good preservation, and enhanced fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Synthesis of Thiocoumarin

[0041]

[0042]Coumarin 6 (0.35 g, 1.0 mmol) and Lawson's reagent (0.81 g, 2.0 mmol) were added into two-necked flasks respectively, and then 15 ml of anhydrous toluene was added into the flasks to form a mixture. A rotor was placed in the flask and the flask was placed in a thermostatically heated magnetic stirrer. A cooling water circulation device was set up, and the mixture was heated to 120 °C under nitrogen protection, and the reaction was continued for 1 day. After the reaction was completed, it was cooled to room temperature.

[0043] The reaction product was extracted with dichloromethane and water, and the resulting product was purified by column chromatography (developing agent ratio PE:DCM=1:2~1:3) to obtain the thio derivative of coumarin (0.23 g, 62%). The high resolution mass spectrum is as follows: 1 H NMR (300 MHz, CDCl 3 ) δ 8.96 (br d, J = 0.6 Hz, 1H), 8.01 (d, J = 8.1 Hz, 1H),7.95(d, J = 7.8 Hz, 1H), 7.53 (d,...

Embodiment 2

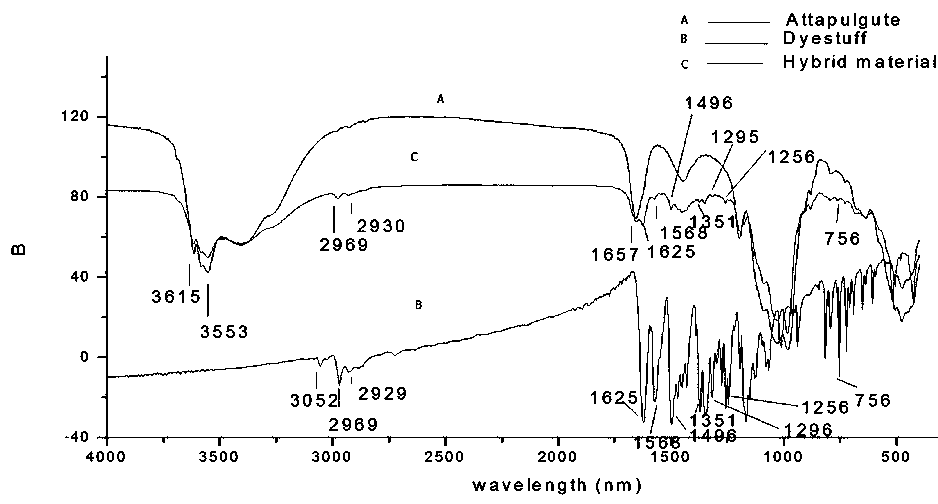

[0051] Example 2: Preparation of attapulgite-thiocoumarin functional hybrid material

[0052] Attapulgite pretreatment:

[0053] Roll the raw ore, grind the attapulgite after passing through a 200-mesh sieve, grind for 5-10 minutes, add deionized water to the attapulgite for beating, and centrifuge to remove the non-clay impurities in the lower layer. The beating speed is 8000rpm, and the beating time is 40min; the centrifugal speed is 3000rpm, centrifugation time is 40min, repeat the beating and centrifuging operation 3~4 times; put the paste-like attapulgite obtained after the above beating and centrifugation into the refrigerator for 6~7 hours, take it out and thaw, and use the attapulgite sample after thawing Squeeze the roller for 5-6 times in the roller machine, scrape off the sample after the roller and replace it with isopropanol solvent to obtain the pretreated attapulgite;

[0054] The isopropanol solvent replacement step is as follows: disperse the sample after the...

Embodiment 3

[0058] Example 3: Preparation of attapulgite-thiocoumarin functional hybrid material

[0059] Attapulgite pretreatment:

[0060] Roll the raw ore, grind the attapulgite after passing through a 200-mesh sieve, grind for 5-10 minutes, add deionized water to the attapulgite for beating, and centrifuge to remove the non-clay impurities in the lower layer. The beating speed is 12000 rpm, and the beating time is 20 minutes; 4000 rpm, centrifugation time is 20min, repeat the beating and centrifuging operation 3~4 times; put the paste-like attapulgite obtained after the above beating and centrifugation into the refrigerator for 6~7 hours, take it out and thaw it, and put the thawed attapulgite The sample is squeezed 5 to 6 times with the pair of rollers, and the sample after the pair of rollers is scraped off and replaced with isopropanol solvent to obtain the pretreated attapulgite;

[0061] The isopropanol solvent replacement step is as follows: disperse the sample after the roller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com