Bifunctional catalyst containing multi-stage pore EUO molecular sieve and preparation method thereof

A bifunctional catalyst, molecular sieve technology, applied in molecular sieve catalysts, catalyst activation/preparation, molecular sieves and base exchange compounds, etc., can solve the problems of poor catalyst selectivity, limited catalytic life of molecular sieves, and high xylene loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

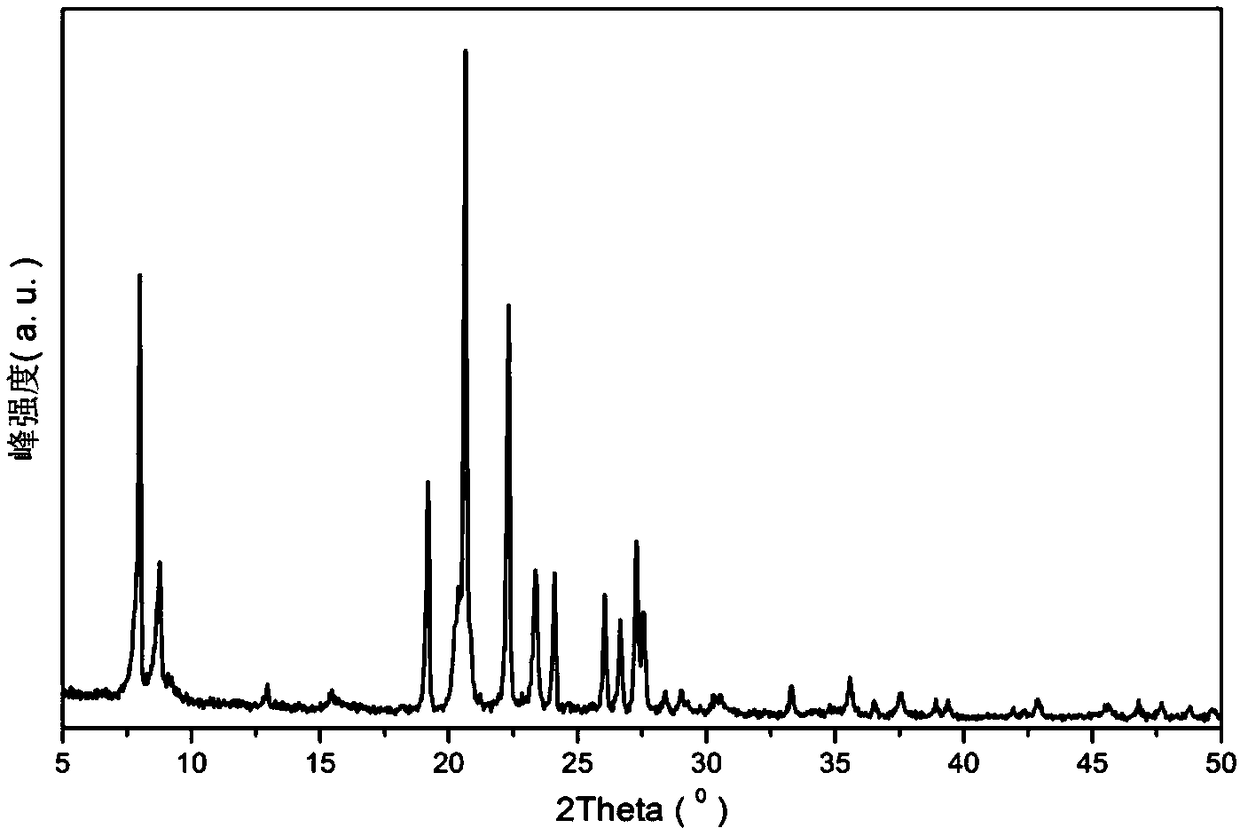

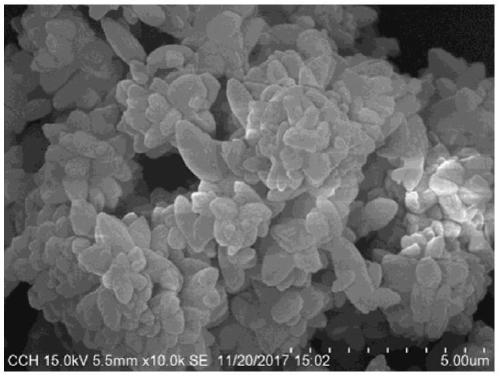

[0065] Example 1: Preparation of hierarchically porous EUO structure EU-1 molecular sieve:

[0066] Weigh a certain amount of cetyltrimethoxysilane and dissolve it in methanol to form a solution and stir to disperse to form a solution of cetyltrimethoxysilane; then add a quantitative amount of cetyltrimethoxysilane to the solution of cetyltrimethoxysilane Water glass, NaOH, 1,6-bis(N-methylpiperidinium)hexane and deionized water H 2 O, stirred at 40°C for 6 hours to obtain a silicon source mixed solution; at 60°C, put a quantitative amount of pseudo-boehmite into the silicon source mixed solution, stirred vigorously for 90 minutes, and aged at room temperature for 12 Obtain mixture mixed sol in hour, mixed sol is used as crystallization precursor mixture, and its composition is:

[0067] Na 2 O:SiO 2 :Al 2 o 3 :LCS:OSDA:H 2 O=0.12:1:0.0211:0.0042:0.08:15;

[0068] The obtained mixed sol was placed in a crystallization kettle, and crystallized at 170°C, wherein the heati...

Embodiment 2~8

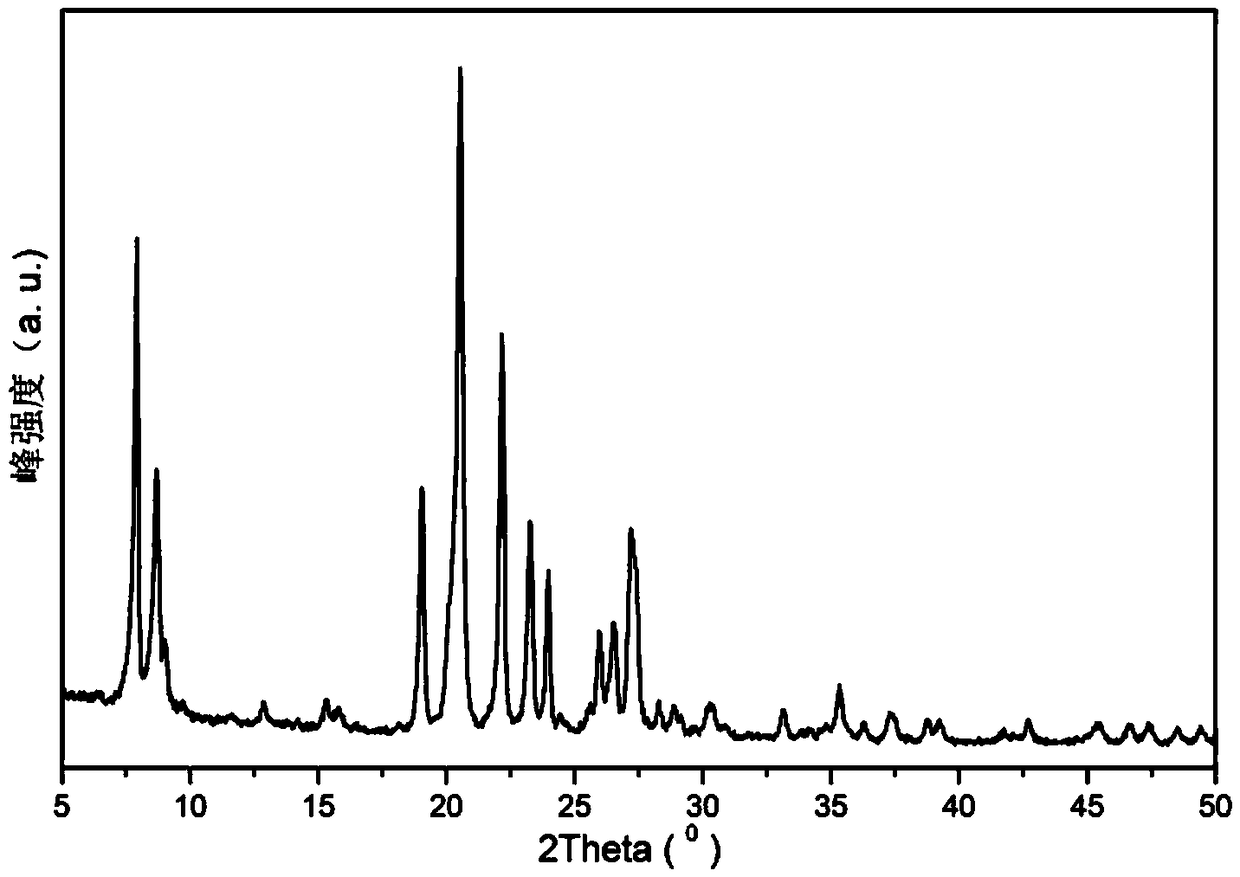

[0074] Examples 2-8: Preparation of EU-1 molecular sieves of hierarchically porous EUO:

[0075] Using the same synthetic method as in Example 1 to synthesize EU-1 molecular sieve with multi-level porous EUO structure, the selected silicon source, aluminum source, long-chain organosilane, double quaternary ammonium salt template type and feeding ratio, heating rate , crystallization temperature, crystallization time and other parameter selections, refer to Table 2; the names of the molecular sieve samples prepared in Examples 2-8 are respectively marked as A~H, and their physical and chemical properties are as shown in Table 3:

[0076] Table 2: Selection of parameters in the EU-1 molecular sieve synthesis method in the examples

[0077]

[0078]

[0079] Table 3: Physical and chemical properties of EU-1 molecular sieve products synthesized in Examples and Comparative Examples

[0080] serial number

Embodiment 9~16

[0081] Embodiment 9~16: preparation catalyst:

[0082] Kneading molding: 20.00 g of the molecular sieves prepared in Examples 1 to 5 and Comparative Examples 1 to 3 were respectively pressed by molecular sieve and Al 2 o 3 The ratio of dry mass proportioning 30:70 is mixed evenly with 59.51g of pseudoboehmite powder (produced by Shandong Aluminum Works, A12O3 content is 78.4wt%), 2.0g of turnip powder, 30g of 2.0wt% citric acid aqueous solution, Extruded, then dried at 120°C for 12 hours, and then calcined at 550°C for 4 hours to obtain the initial carrier.

[0083] Ion exchange: Take 25.0g of the above initial carrier and 250g of NH with a concentration of 1.0mol / L 4 The Cl aqueous solution was subjected to ion exchange at 90°C under continuous stirring for 3 hours, and the exchange was repeated twice, washed with deionized water until there was no chloride ion, filtered and recovered, then the particles were dried at 110°C for 12 hours, and finally calcined at 550°C for 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com