Micronized powder active carbon for water treatment and preparation method thereof

A technology of powder activated carbon and miniaturization, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, etc. It can solve the problems of low adsorption efficiency and powder activated carbon can not meet the requirements of water treatment, etc., to improve the adsorption rate and adsorption capacity, enhanced adsorption capacity, and reduced diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

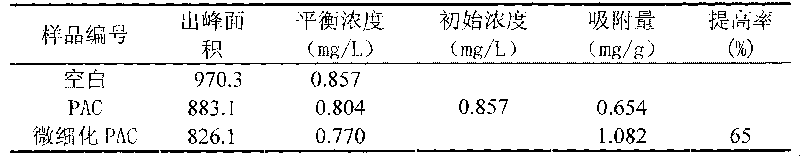

[0019] Put the commercially available coal-based powdered activated carbon with a particle size of 325 mesh into the airflow ultrafine pulverizer, and pulverize it three times under the conditions of the airflow velocity of 300m / s and the pressure of 1.2MPa, and pulverize the powdered activated carbon into fine particles with an average particle size of ≤10μm. powder to produce micronized powdered activated carbon. The prepared micronized powdered activated carbon and traditional powdered activated carbon were placed in a vacuum environment at a temperature of 105°C and dried for 6 hours, and then put into water containing dimethyl sulfide respectively at a feeding ratio of 80 mg / L, and oscillated at a constant temperature until adsorption equilibrium , using purge-and-trap gas chromatography (FID detector) to detect the concentration of methyl sulfide in water, and the detection result data are shown in Table 1.

[0020] Table 1 adopts the micronization powder activated carbo...

Embodiment 2

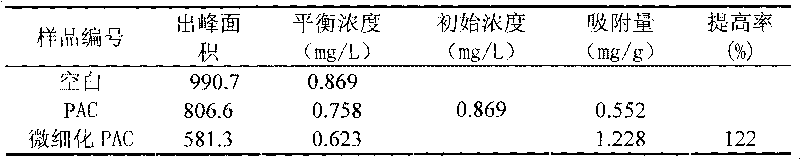

[0024] Add commercially available wood powder activated carbon with a particle size of 200 mesh into a vibrating mill, grind for 2 hours under the input of mechanical energy 100W / L, and pulverize the powdered activated carbon into a fine powder with an average particle size of ≤10 μm to obtain a micronized powdered activated carbon . The prepared micronized powdered activated carbon and traditional powdered activated carbon were placed in a vacuum environment at a temperature of 105°C and dried for 6 hours, and then put into water containing dimethyl sulfide respectively at a feeding ratio of 200mg / L, and oscillated at a constant temperature until adsorption equilibrium , using purge-and-trap gas chromatography (FID detector) to detect the concentration of methyl sulfide in water, and the detection result data are shown in Table 2.

[0025] Table 2 adopts the data comparison table of the micronization powder activated carbon that the inventive method makes and commonly used po...

Embodiment 3

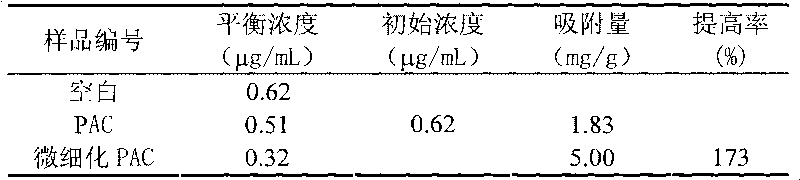

[0029] Add commercially available activated carbon from shells with a particle size of 100 mesh into a dry stirring mill, grind for 0.5 hours under the input of mechanical energy 1000W / L, and pulverize the powdered activated carbon into a fine powder with an average particle size of ≤10 μm to obtain a fine powder powdered activated carbon. The prepared micronized powdered activated carbon and traditional powdered activated carbon were dried in a vacuum environment at a temperature of 105 °C for 6 h, and then put into 2+ In the water, the feeding ratio is 60mg / L, and the constant temperature is oscillated to the adsorption equilibrium, and the Cu in the water is detected by ICP AES atomic emission spectrometry. 2+ Concentration, detection result data are shown in table 3.

[0030] Table 3 adopts the miniaturization powder activated carbon that the inventive method makes and commonly used powder activated carbon to water Cu 2+ Adsorption capacity data comparison table

[0031...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com