Oil-proof PVC sheath material for earphone wire

A sheath material and earphone cable technology, applied in the directions of earphones/earphone accessories, etc., can solve the problems of losing the softness of the earphone cable, being easily corroded by oil products, and having poor oil corrosion resistance, and achieving a bright and smooth appearance and easy outer diameter. Control, the effect of early plasticization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0010] The oil-resistant grade PVC sheath material for earphone cables consists of 48 parts of WS-1300, 25 parts of W-2050, 22 parts of a mixed filler composed of HD2500 and CCR-603 in a weight ratio of 1:1, 3 parts of YC-300, 1.5 parts 1 part of LOCK and 0.3 part of UV-201 are used as raw materials, uniformly mixed, extruded and granulated by a twin-screw extruder to obtain a PVC sheath material.

[0011] In the above examples, WS-1300 can also be 45 parts or 50 parts, etc.; W-2050 can also be 25 parts, 28 parts, 32 parts or 35 parts, etc.; the mixed filler can also be 20 parts or 25 parts, etc., wherein The weight ratio of HD2500 and CCR-603 can also be 1:2, etc.; YC-300 can also be 2 or 5 parts; LOCK can also be 2 or 0.5 parts; UV-201 can also be 0.1 or 0.5 Parts, etc.; not one by one examples here.

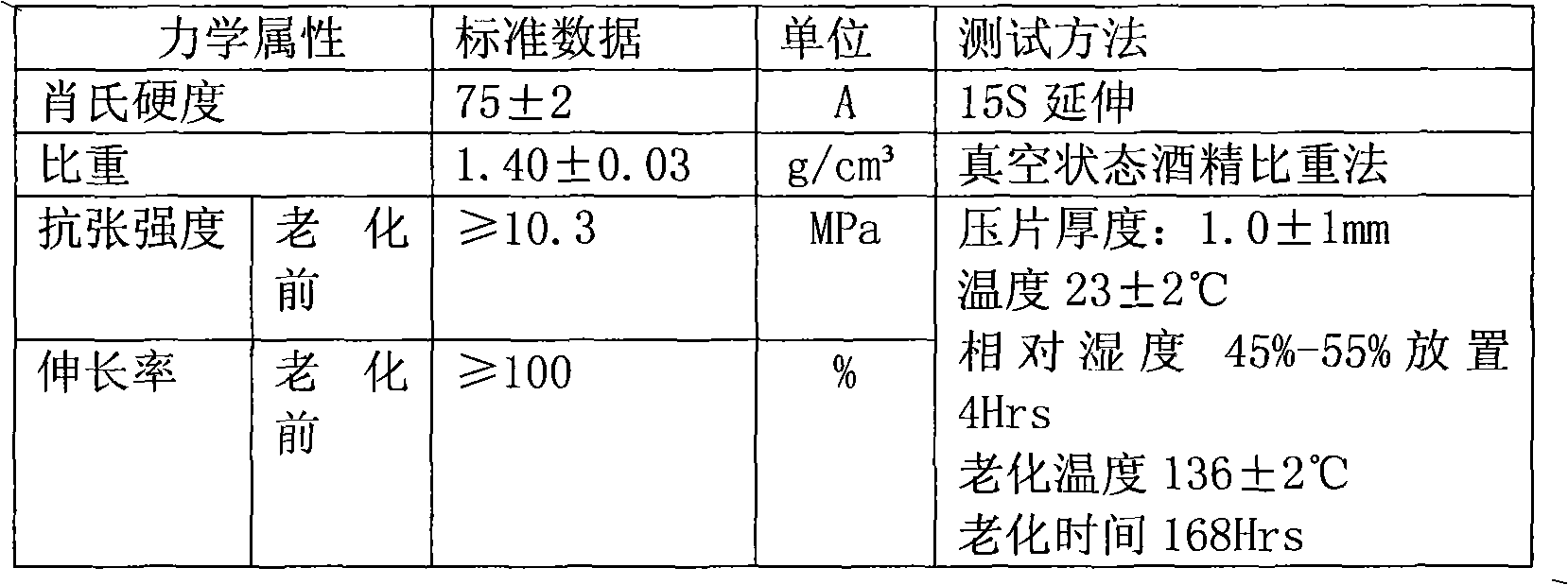

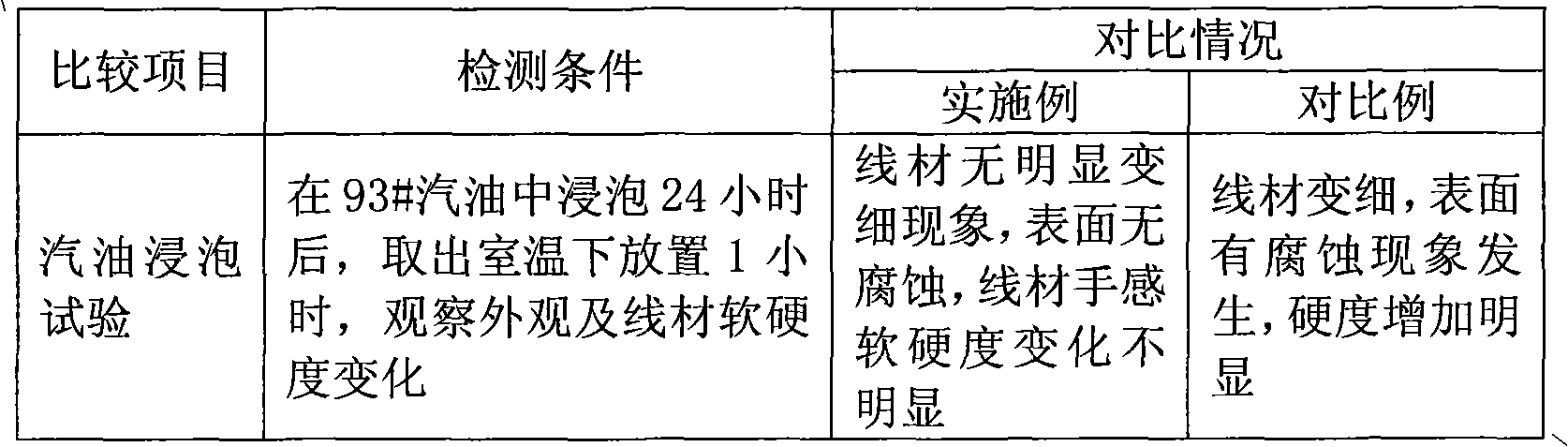

[0012] The PVC sheath material of the present invention is carried out mechanical property measurement test and obtains the result as table 1, can find out from table 1 that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com