Preparation method of polyoxymethylene dimethyl ethers

A technology of dimethyl ether and polyoxymethylene, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve problems such as catalyst corrosion, and achieve good technical effects, catalyst activity and target product selectivity improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

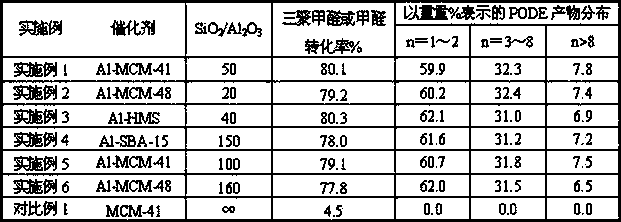

[0018] The performance evaluation of the catalyst was carried out on a 300ml autoclave reaction device. Add 2 grams of catalyst, 100 grams of methanol, and 100 grams of paraformaldehyde in the autoclave, and react for 2 hours at 130 ° C and a pressure of 6 MPa by filling nitrogen, filter and separate the catalyst and the reaction product, and analyze the obtained mixture by gas chromatography The composition is shown in Table 1. The catalyst is Al-MCM-41, its SiO 2 / Al 2 o 3 The molar ratio was 50.

[0019]

Embodiment 2

[0021] According to the steps of [Example 1], except that the catalyst uses a different catalyst, add 1.5 grams of catalyst, 100 grams of methanol, and 150 grams of paraformaldehyde, and react for 2 hours at 120 ° C and under a pressure of 6 MPa by filling nitrogen gas. The specific test The conditions and reaction results are shown in Table 1.

[0022]

Embodiment 3

[0024] According to the steps of [Example 1], except that the catalyst uses a different catalyst, add 2 grams of catalyst, 80 grams of methanol, and 200 grams of paraformaldehyde, and react for 5 hours at 130 ° C and under a pressure of 4 MPa by filling nitrogen. The specific test The conditions and reaction results are shown in Table 1.

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com