Ultra-hard diamond-like antireflection film, infrared material comprising antireflection film as well as preparation method and application of antireflection film

A technology of diamond-like film and infrared material, which is applied in the field of infrared material and its preparation, superhard diamond-like anti-reflection film, which can solve the problems of anti-heavy friction of infrared window and limitation of high-speed wind and sand wear, and achieve strong resistance to seawater and other chemical factors for a long time Corrosion, strong high-speed wind and sand erosion, anti-heavy friction and high-speed wind and sand erosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

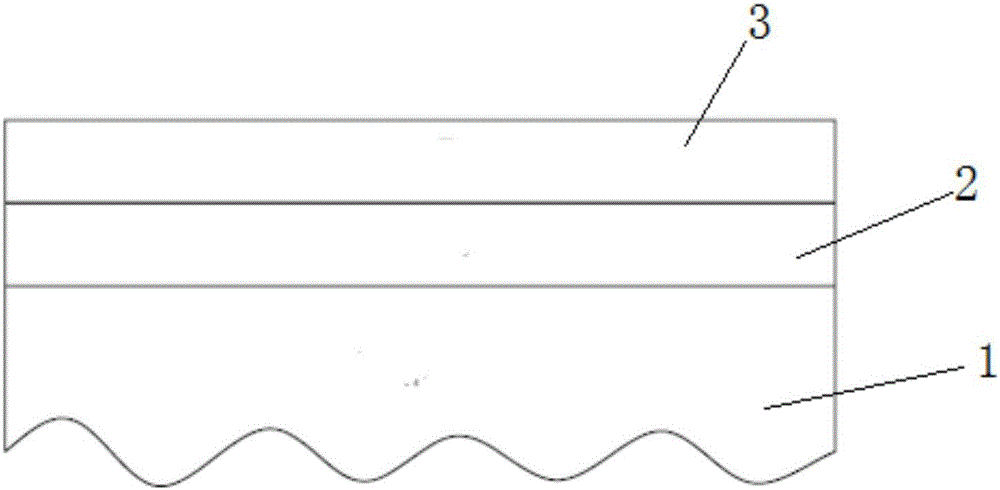

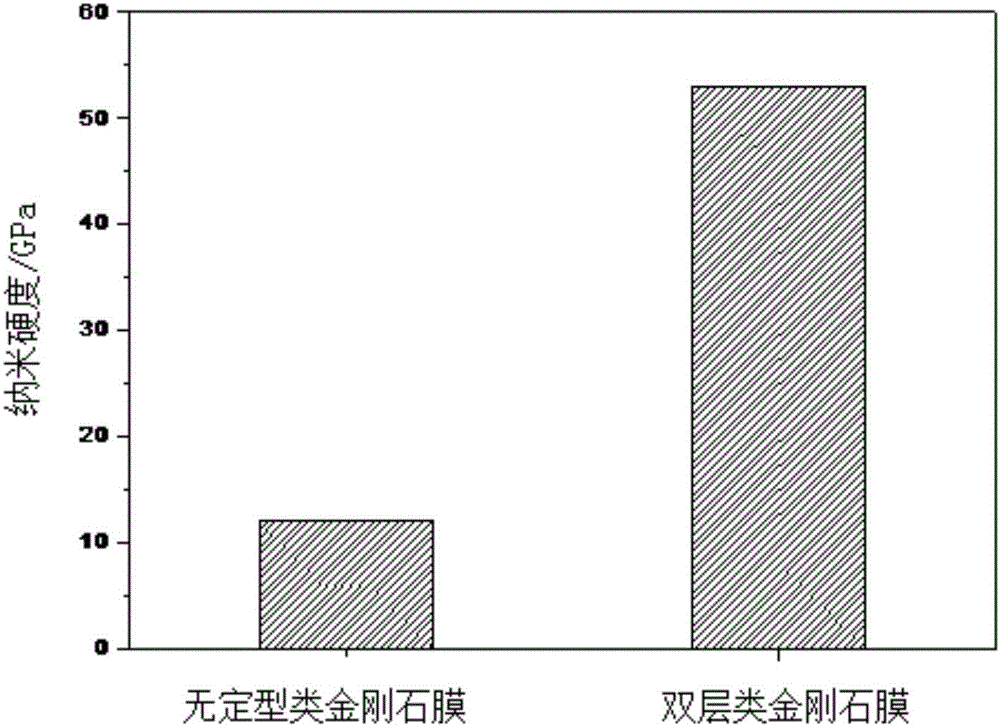

[0035] Plating a-C:H / ta-C double-layer superhard diamond-like film on the Ge substrate is anti-reflection in the 8-12μm segment, and the center wavelength is 9μm. If the thickness of the two films is the same, the refractive index of a-C:H 2. The refractive index of ta-C is 2.7, and the physical thickness of the two films is 475nm, such as figure 1 shown.

[0036] (1) Use a dust-free cloth to polish the double-sided Φ50×2 Ge substrate, drop alcohol and wipe it under strong light.

[0037] (2) Put the substrate on the lower plate of the PECVD equipment and vacuumize to 3×10 -3 Pa, adjust the radio frequency power 200-2000w, plate the bottom a-C:H film, and the plating time is 10min.

[0038] (3) Place the substrate coated with a-C:H film on the target holder of the FCVA equipment so that it forms an angle of 45° with the beam. Adjust the bias voltage and the size of the arc current, and plate a ta-C film on the a-C:H film for 55 minutes.

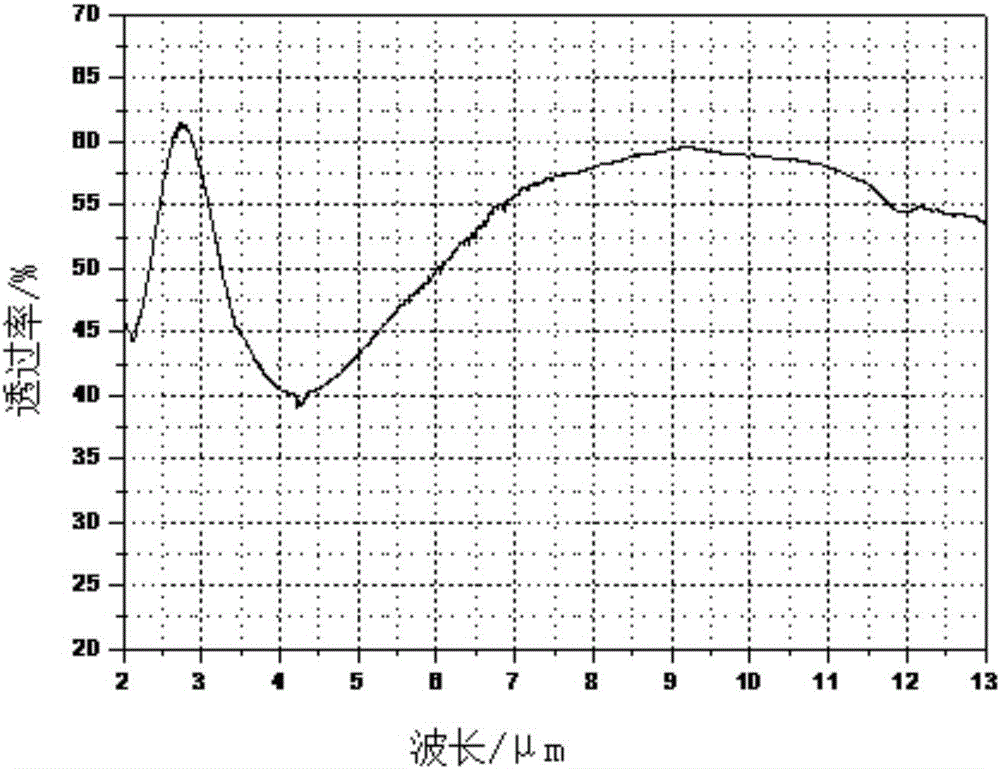

[0039] (4) The transmittance test ...

Embodiment 2

[0045] The a-C:H / ta-C double-layer superhard diamond-like film is plated on the Ge substrate to increase the reflection in the 8-12μm segment, and the center wavelength is 9μm. According to the film system design software Essential Macleod software design, the refractive index of a-C:H 2, the physical thickness is 794nm, the refractive index of ta-C is 2.7, and the physical thickness is 213nm.

[0046] (1) Use a dust-free cloth to polish the double-sided Φ60×2 Ge substrate, drop alcohol and wipe it under strong light.

[0047](2) Put the substrate on the lower plate of the PECVD equipment and vacuumize to 3×10 -3 Pa, adjust the radio frequency power to 200-2000w, plate the bottom a-C:H film, and the plating time is 18min.

[0048] (3) Place the substrate coated with a-C:H film on the target holder of the FCVA equipment so that it forms an angle of 45° with the beam. Adjust the bias voltage and the size of the arc current, and plate a ta-C film on the a-C:H film for 25 minute...

Embodiment 3

[0051] Plating a-C:H / ta-C double-layer superhard diamond-like film on the Si substrate is anti-reflection in the 3-5μm segment, and the center wavelength is 4μm. If the thickness of the two films is the same, the refractive index of a-C:H is 2, The physical thickness is 212nm, the refractive index of ta-C is 2.7, and the physical thickness is 212nm.

[0052] (1) Wipe the double-sided polished Φ55×2 Si substrate with a dust-free cloth dipped in alcohol under strong light.

[0053] (2) Put the substrate on the lower plate of the PECVD equipment and vacuumize to 3×10 -3 Pa, adjust the radio frequency power to 200-2000w, plate the bottom a-C:H film, and the plating time is 8.6min.

[0054] (3) Place the substrate coated with a-C:H film on the target holder of the FCVA equipment so that it forms an angle of 55° with the beam. Adjust the bias voltage and the size of the arc current, and plate a ta-C film on the a-C:H film for 9.4 minutes.

[0055] (4) a-C:H / ta-C double-layer film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Physical thickness | aaaaa | aaaaa |

| Nanohardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com