Carrier roller bearing assembly and carrier roller with bearing assembly

A bearing assembly and idler technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the work and life impact of belt profile workers, the inability of metal idlers to adapt to the development trend, and the large jump of metal idlers. and other problems, to achieve the effect of light weight, low friction coefficient and low rotational resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

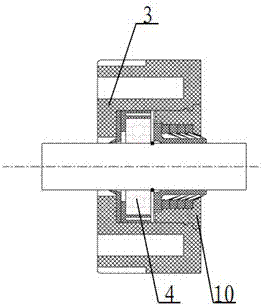

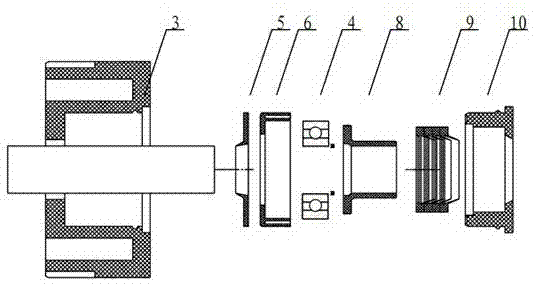

[0025] Figure 1 to Figure 4 The structural schematic diagrams of the bearing assembly for the idler roller and the idler roller according to the preferred embodiment of the present invention are respectively shown. exist Figure 4 Among them, the idler roller includes a roller body 1, an idler shaft 2 passing through the roller body 1 along the rotation axis of the roller body 1, and a bearing assembly. The bearing assembly at least includes: bearing housing 3, bearing 4, bottom sealing ring 5, bushing 8. Shaft sleeve sealing ring 9 and sealing cover 10, such as figure 1 shown.

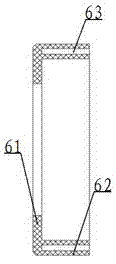

[0026] The roll body 1 is cylindrical, and is formed by extruding a modified ultra-high molecular weight polyethylene pipe mainly made of ultra-high molecular weight polyethylene through an extruder. The roller body 1 made of ultra-high molecular weight polyethylene material has high impact resistance, high wear resistance, corrosion resistance, self-lubrication, no fouling, weather resistance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com