Fracturing fluid prepared by recovery waste water of crude oil and preparation method of fracturing fluid

A fracturing fluid and sewage technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult to meet fracturing construction, vegetable glue layering, high salinity, etc., to reduce water lock damage, The effect of increasing production and alleviating the demand for water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The water quality analysis of crude oil production sewage (salinity below 40,000) in a certain well in oilfield A is shown in Table 1.

[0036] Table 1 Water quality analysis of crude oil extraction wastewater

[0037]

[0038] According to 0.6% by weight of thickener, 0.05% by weight of metal ion stabilizer, 0.03% by weight of waterproof locking agent, 0.1% by weight of high temperature stabilizer, 1% by weight of clay stabilizer, and the balance is the above-mentioned oil production sewage, prepare fracturing fluid base fluid.

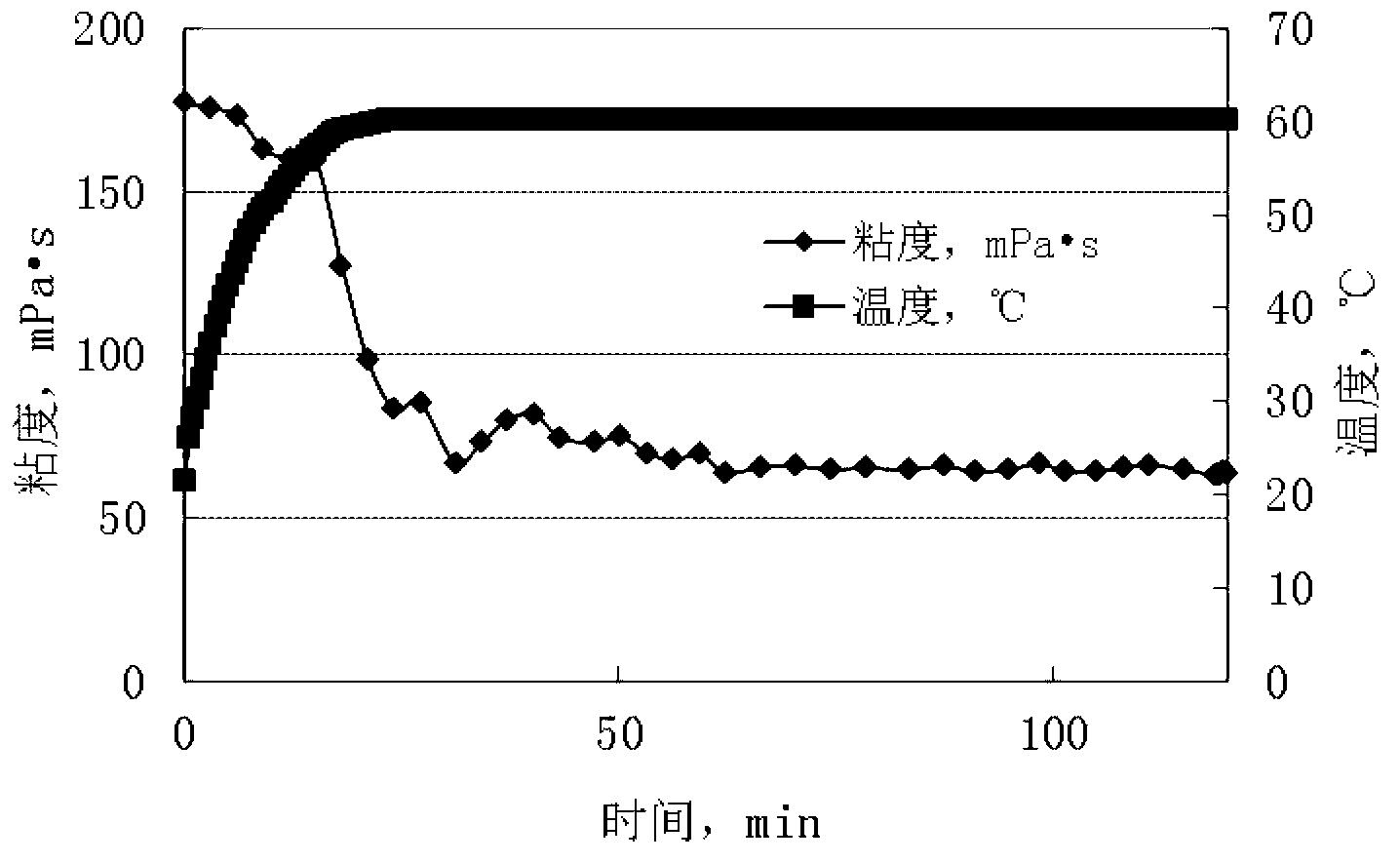

[0039] Add 0.03% by weight of a thickening auxiliary agent to the fracturing fluid base fluid and mix well to obtain a viscoelastic fracturing fluid. Use a high-temperature rheometer to test the temperature and shear resistance of fracturing fluid at 60°C. The test curve is shown in figure 1 . From the temperature and shear resistance test at 60°C, it can be seen that in 170s -1 In the case of continuous shearing, the viscosity of the f...

Embodiment 2

[0041] Use the above-mentioned crude oil production sewage, according to 0.8% by weight of thickener, 0.05% by weight of metal ion stabilizer, 0.03% by weight of waterproof locking agent, 0.15% by weight of high temperature stabilizer, 1% by weight of clay stabilizer, prepare fracturing fluid base fluid.

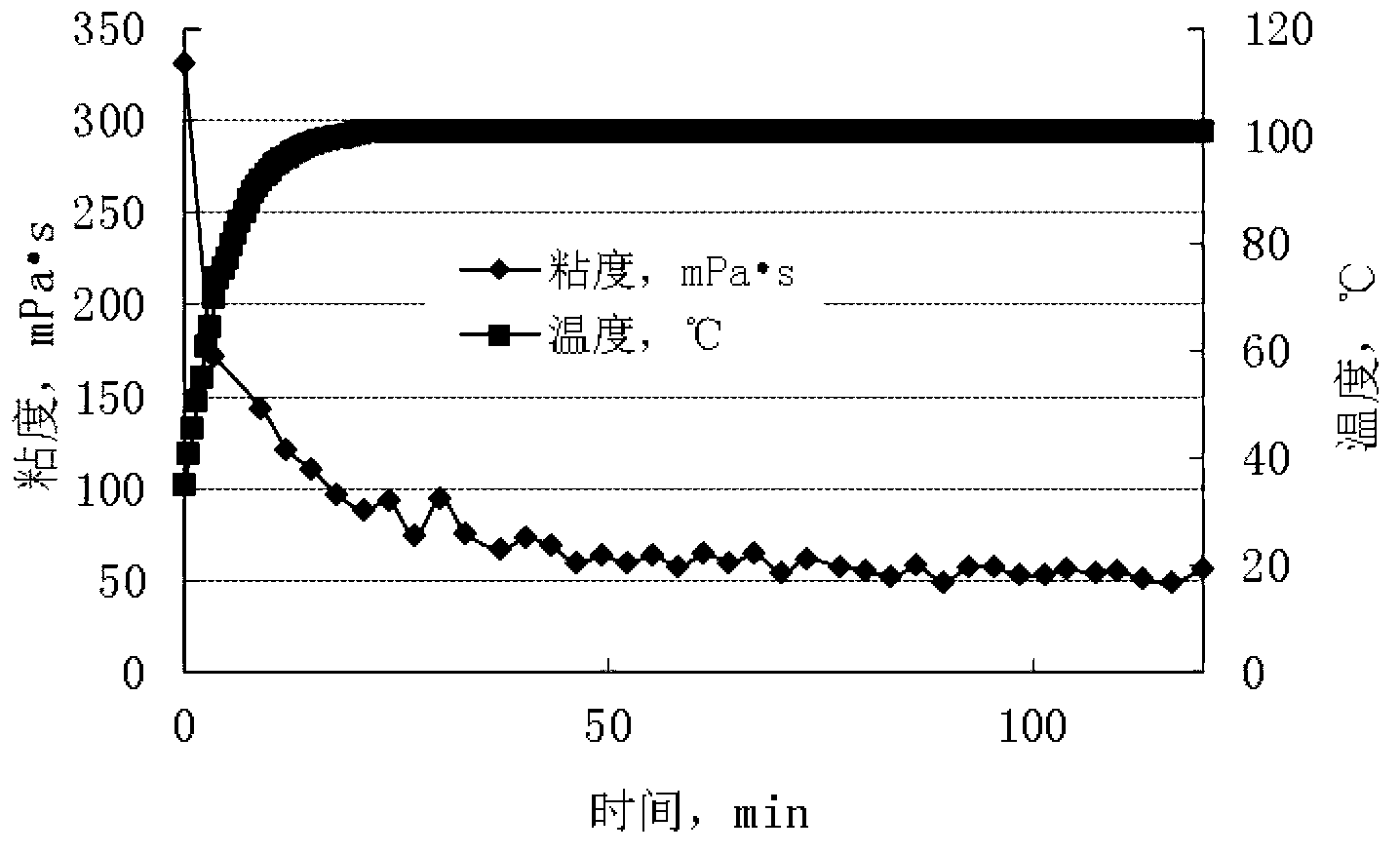

[0042] Add 0.04% by weight of a thickening auxiliary agent to the fracturing fluid base fluid and mix well to obtain a viscoelastic fracturing fluid. Use a high-temperature rheometer to test the temperature and shear resistance of fracturing fluid at 100°C. The test curve is shown in figure 2 , it can be seen from the temperature and shear resistance test at 100℃ that in 170s -1 In the case of continuous shearing, the viscosity of the fracturing fluid is always greater than 50 mPa s, indicating that the system has good temperature and shear resistance.

Embodiment 3

[0044] 1. On-site dosing

[0045] Prepare 180 cubic meters of crude oil production wastewater from oilfield A, put it into six 30-square-meter tanks, prepare the base liquid with jet technology, and circulate and inhale each additive into each tank of crude oil production sewage in turn according to the formula in Table 2, and circulate evenly to The apparent viscosity is greater than 30mPa·S, the thickener is inhaled slowly, subject to no agglomeration and fish eyes, check the viscosity of the liquid after the circulation is uniform.

[0046] Table 2 Fracturing fluid additive formula

[0047]

[0048]

[0049] 2. On-site construction

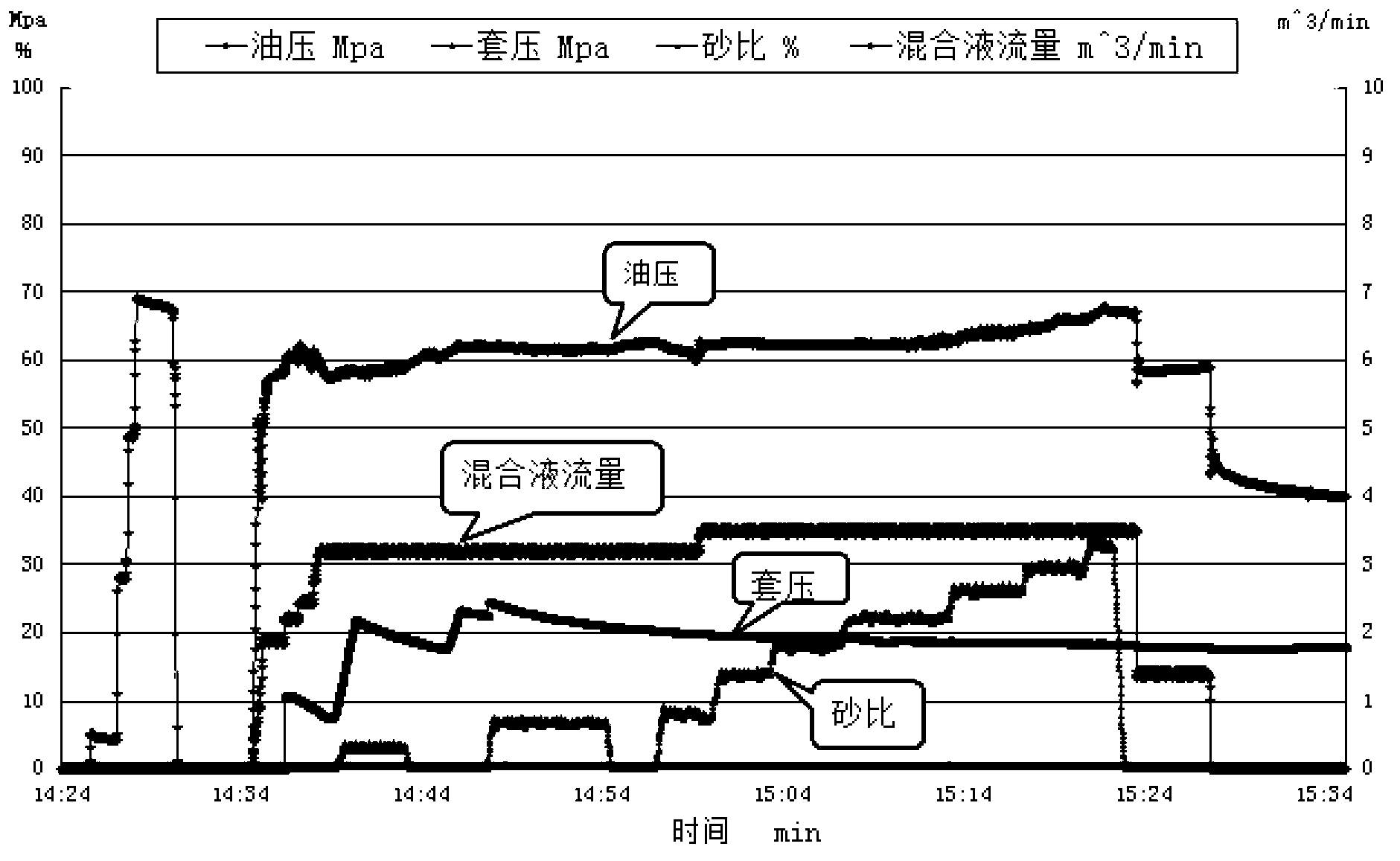

[0050] The formation temperature is 73°C, and the φ73mm N80 tubing is used for injection construction, and the packer protects the casing. During the fracturing construction process, add 0.03% by weight of thickening auxiliary agent to the base fluid from the sand mixer, add 0.03-0.05% by weight ammonium persulfate capsules in the pre-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com