No-blocking pollution discharging pump

A sewage pump, non-clogging technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of old-fashioned sewage pumps, such as complex structure, easy to produce pores and sand inclusions, and rough black outer surface, so as to avoid the decline of insulation level , multi-organic solvent corrosion, good anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

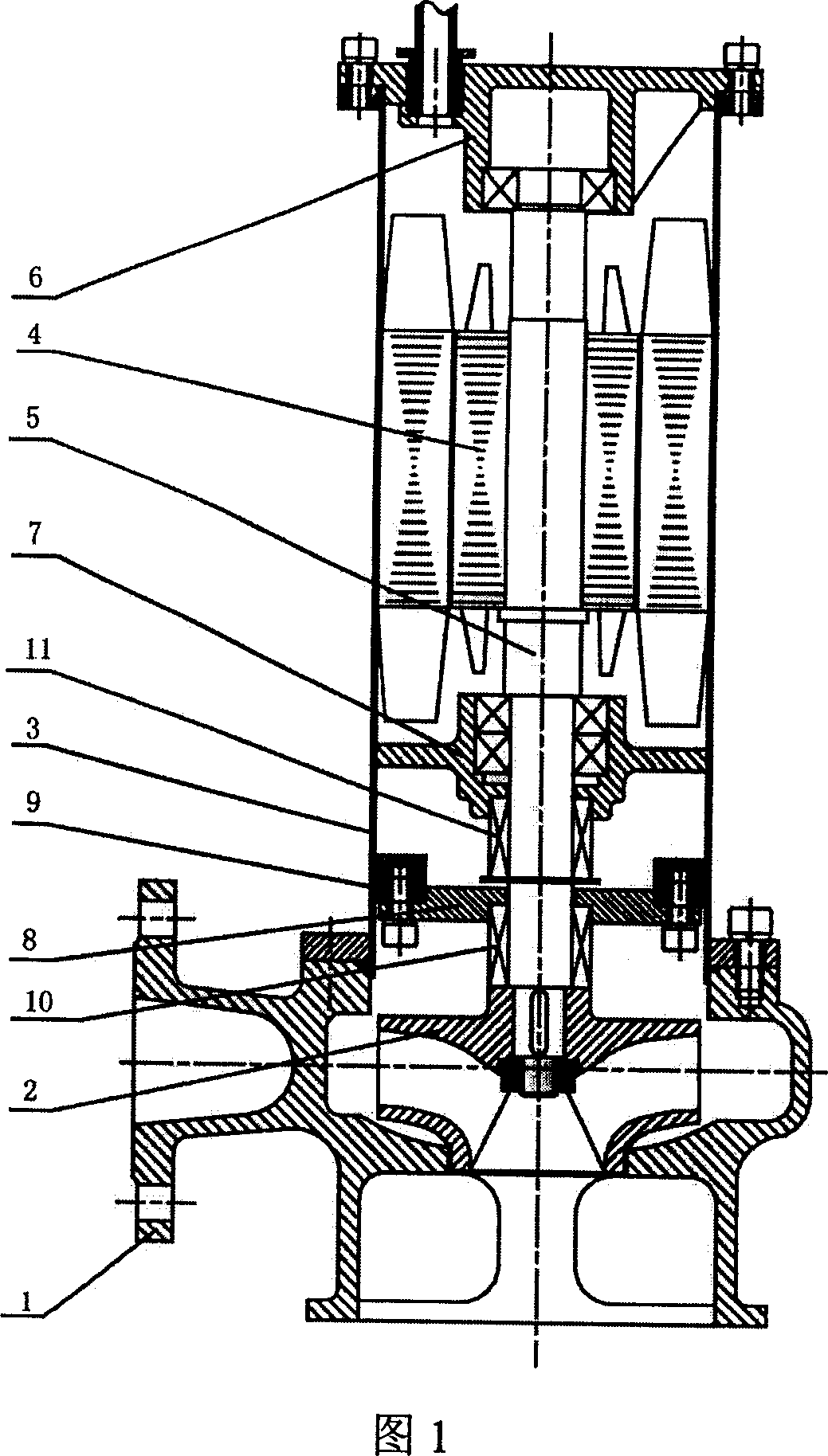

[0028] As shown in Figure 1, a non-clogging sewage pump includes a pump body 1, an impeller 2, a motor, a sealed oil chamber, and a mechanical seal. The impeller 2 is a double-channel structure, and the impeller 2 is arranged in the pump body 1. The motor comprises a stainless steel shell 3, a rotor 4, a shaft 5, a flanged upper bearing seat 6, and a lower bearing seat 7, wherein the flanged upper bearing seat 6 is arranged on the upper end of the stainless steel shell 3, and the lower bearing seat 7 is arranged In the stainless steel shell 3, the flanged upper bearing seat 6 and the lower bearing seat 7 support the rotation of the rotor 4 and the shaft 5. The sealed oil chamber includes an oil chamber gland 8, and the sealed oil chamber is formed by the oil chamber gland 8 , stainless steel shell 3, lower bearing seat 7, the lower end of the stainless steel shell 3 is connected with the pump body 1. The lower bearing seat 7 is welded on the inner wall of the stainless steel s...

Embodiment 2

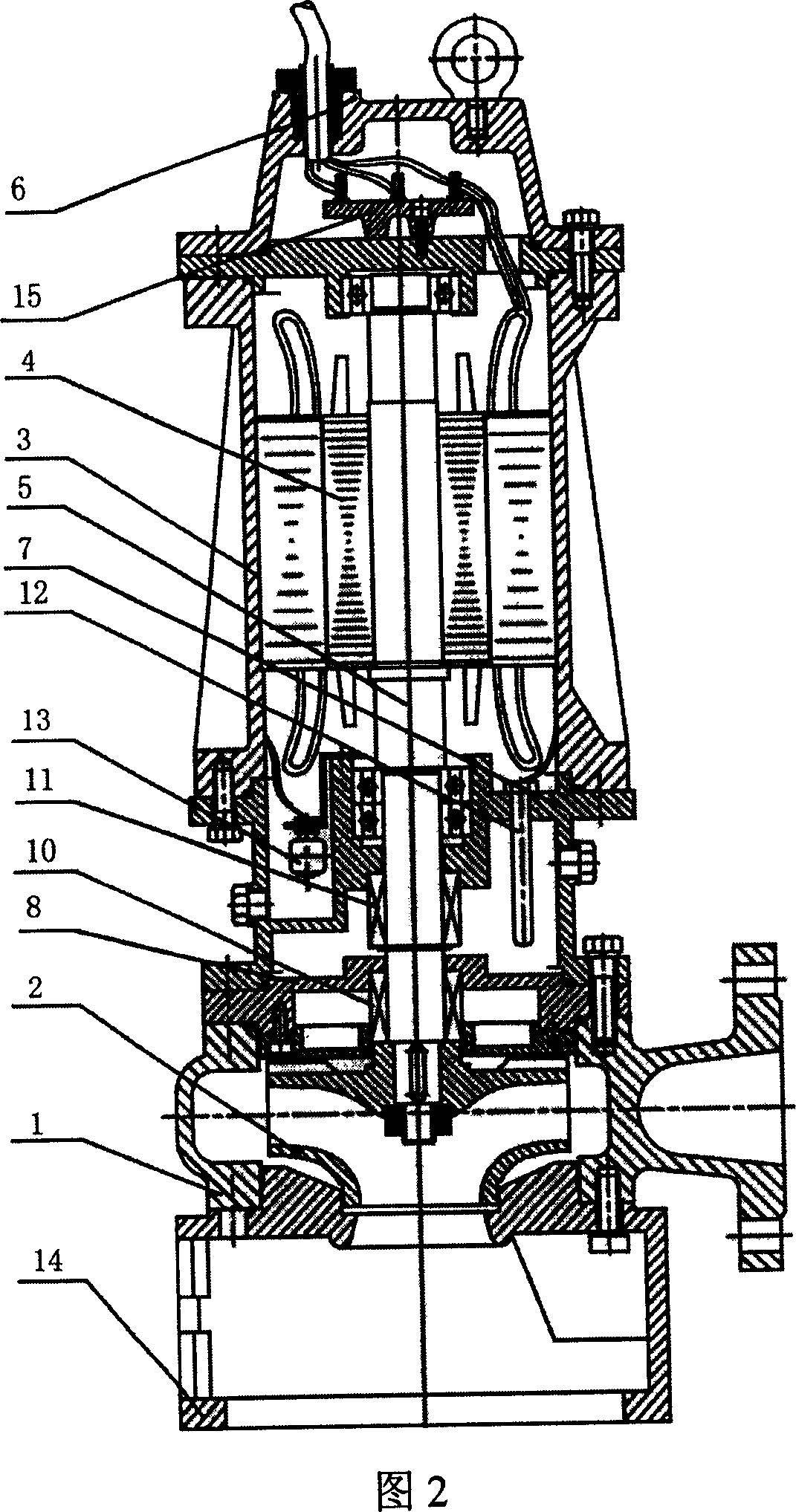

[0030] As shown in Figure 2, a non-clogging sewage pump includes a pump body 1, an impeller 2, a motor, a sealed oil chamber, a mechanical seal, an oil-water detection probe 12, a leakage alarm 13, a thermal element, a bracket 14, and a terminal 15. The impeller 2 has a double-channel structure, and the impeller 2 is set in the pump body 1. The motor includes a stainless steel casing 3, a rotor 4, a shaft 5, a flanged upper bearing seat 6, and a lower bearing seat 7. Among them, the flange-type upper bearing seat 6 is arranged on the upper end of the stainless steel shell 3, and the lower bearing seat 7 is arranged in the stainless steel shell 3, and the flange-type upper bearing seat 6 and the lower bearing seat 7 support the rotation of the rotor 4 and the shaft 5. The sealed oil chamber includes an oil chamber gland 8, and the sealed oil chamber is composed of the oil chamber gland 8, the stainless steel casing 3, and the lower bearing seat 7, and the lower end of the stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com