Multipurpose glue bottle

A glue bottle and soft bottle technology, applied in the field of glue bottles, can solve the problems of inconvenient glue brushing, inconvenient glue application, and unsuitable glue application, etc., and achieve the effects of easy popularization and application, simplified supply and demand varieties, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

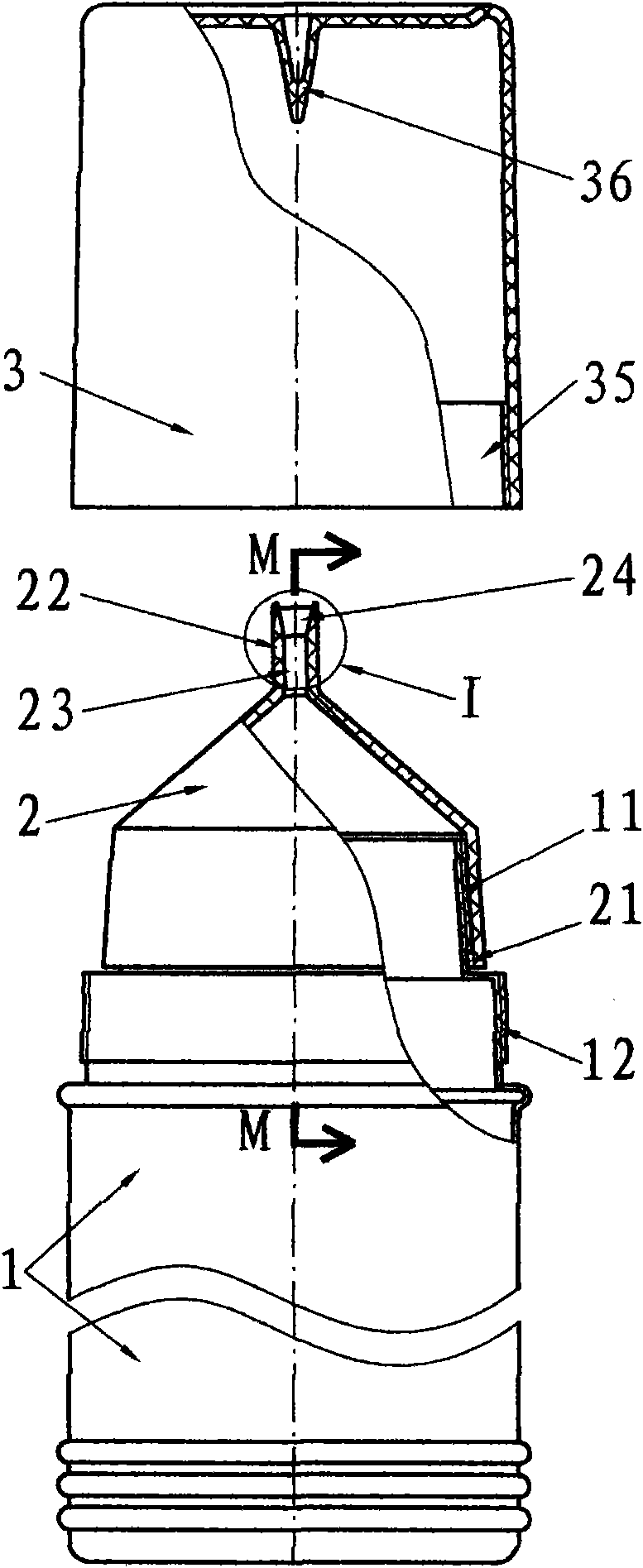

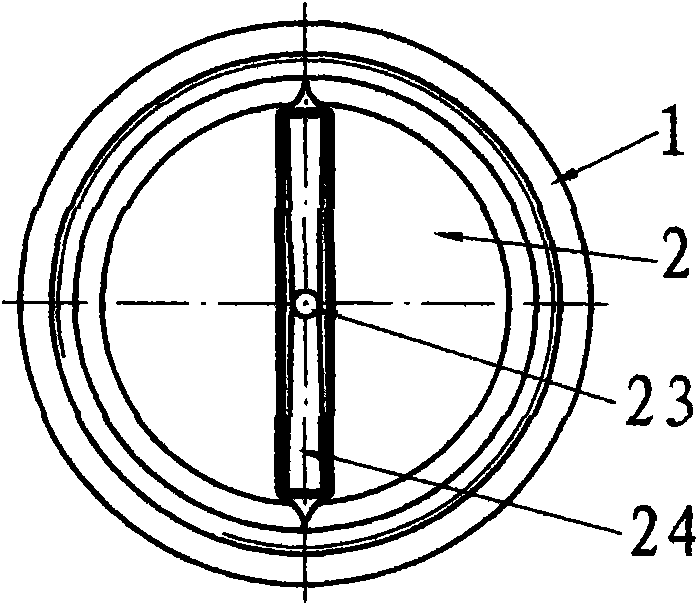

[0046] The multi-applicable glue bottle of the embodiment of the present invention one (construct sees Figures 1 to 8 and Figure 17 and Figure 18), including a soft bottle body 1 and a rubber brushing head 2 connected to it with a glue outlet 23, the glue outlet 23 communicates with the inner cavity of the soft bottle body 1, and the upper end of the rubber brush head 2 is provided with a flat Tongue-shaped flat brush head 22; the end of flat brush head 22 and along its longitudinal direction are provided with a flat mouth-shaped flow tank 24; The glue extruded from the body 1 first flows through the glue outlet 23 and is stored in the flow tank 24 .

[0047] The above-mentioned flat brush head 22 is an integral structure with the rubber brush head 2 . The center of the above-mentioned reservoir 24 coincides with the center of the flat brush head 22 . The above-mentioned glue outlet hole 23 is a circular hole and is located at the center position of the above-mentioned ...

Embodiment 2

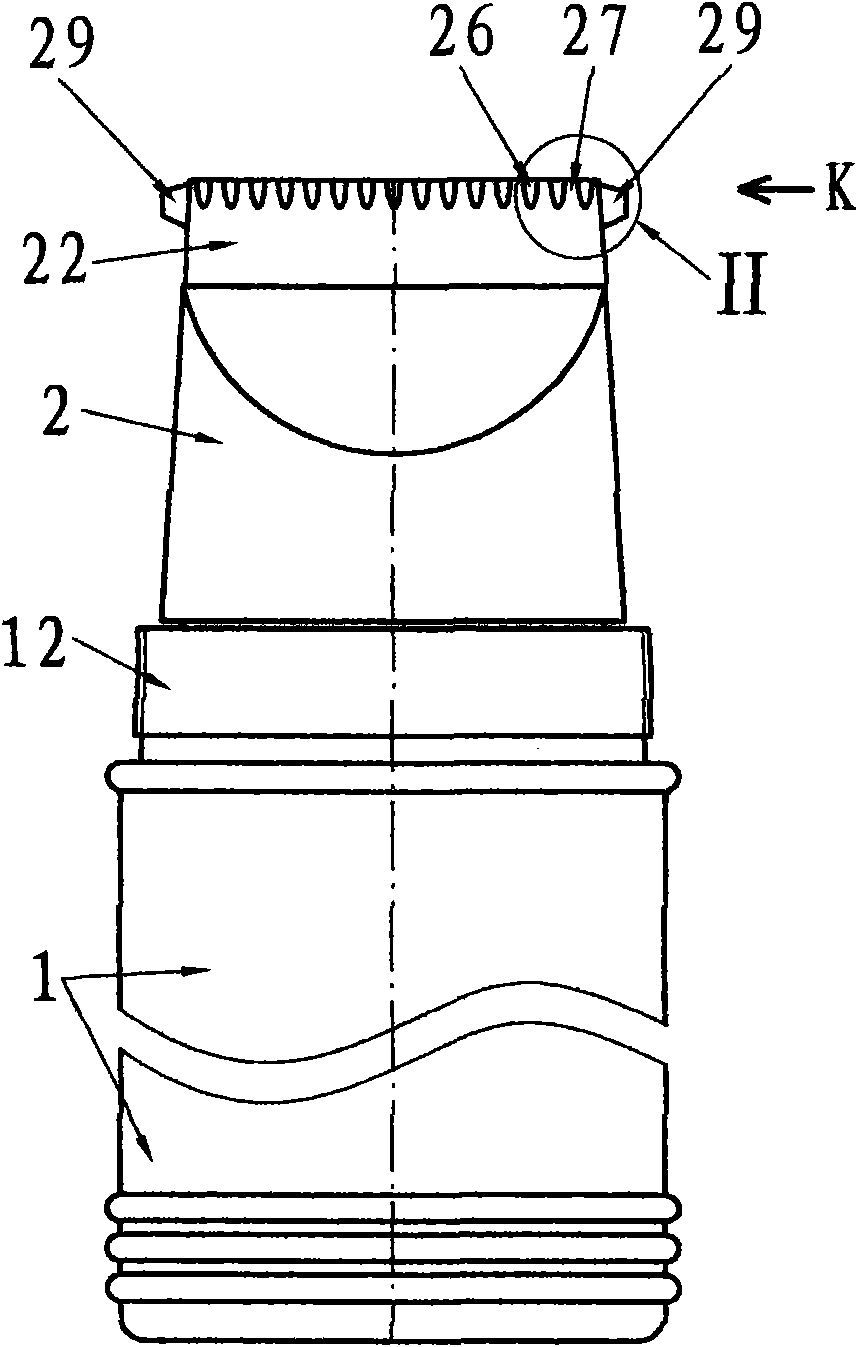

[0065] A kind of multi-purpose glue bottle of embodiment two of the present invention (construct sees Figure 9 to Figure 18 ) is the same as that of Embodiment 1, the difference is that: the above-mentioned flow storage tank 24 is a tapered concave shape 32 that is gradually lowered from its two ends and along its longitudinal direction to its center; the peripheral end of the above-mentioned flow storage tank 24 is set along There are several evenly distributed wave-shaped end grooves 31, the two ends of the wave-shaped end grooves 31 are respectively located on the inside and outside of the storage tank 24, the groove side of the wave-shaped end grooves 31 and the end surface of the above-mentioned flat brush head 22 are separated by The arc transition connection, the overall shape is similar to waves.

[0066] When the two outer edges of the flat brush head 22 in the second embodiment are provided with the side brush grooves 26 as described in the first embodiment, the not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com