Eddy water curtain type rinsing toilet

A toilet, water curtain technology, applied in flushing toilets, water supply devices, urinals, etc., can solve the problems of scrubbing force, poor visual effect, cracking at the edge of the hole, complicated process, etc., so as to enhance the scrubbing effect and improve the scrubbing strength. , The effect of simplifying the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

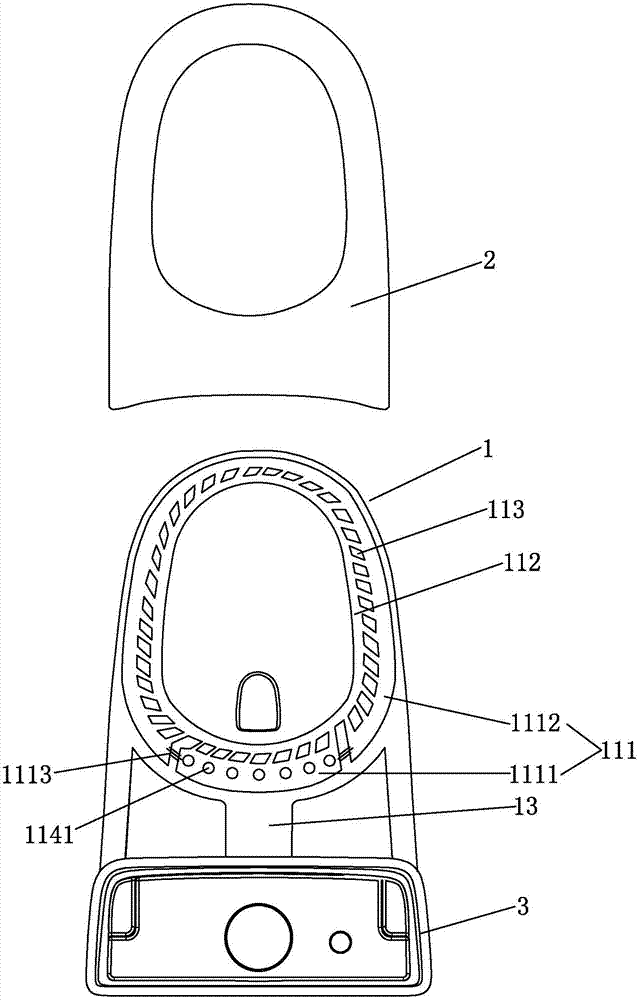

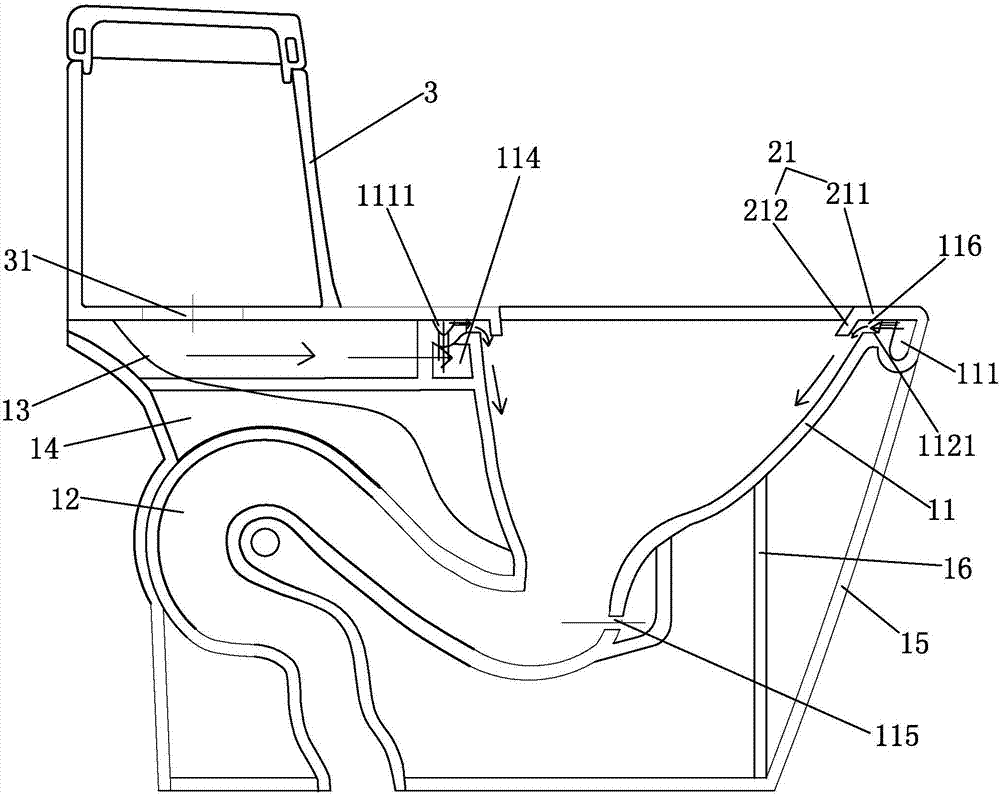

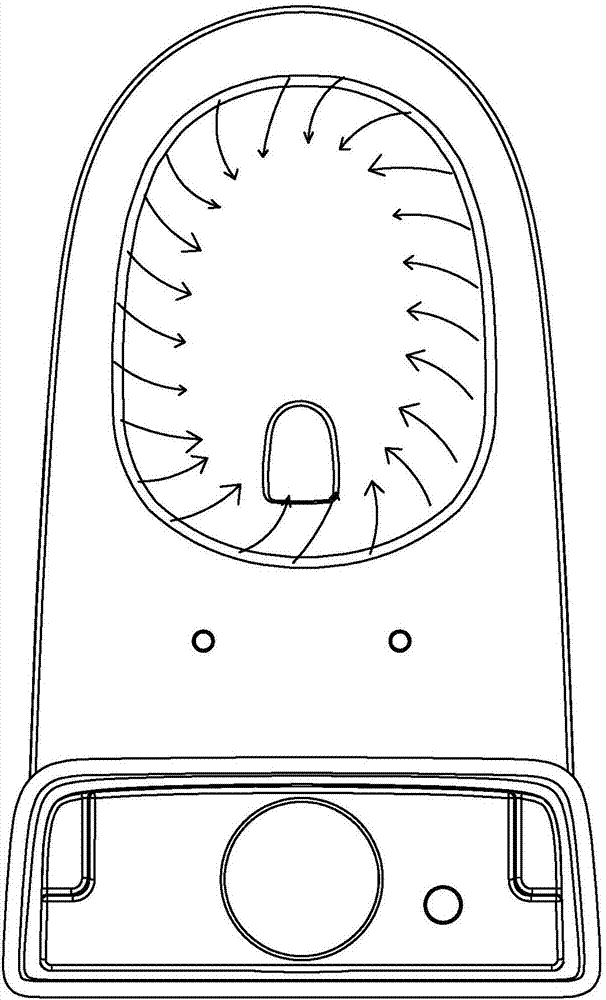

[0024] See Figure 1-Figure 3 As shown, a vortex water curtain type washing toilet of the present invention includes a toilet body, which is provided with a bedpan 11, a sewage pipe 12, and a flushing waterway 13, and the sewage inlet of the sewage pipe 12 leads to the bottom of the bedpan 11 . The sewage pipe 12 is specifically a siphon pipe, and the toilet body is also provided with a spray channel 14, and the bottom of the bedpan 11 is provided with a spray hole 115, and the spray hole 115 is arranged opposite to the sewage inlet of the sewage pipe 12. The top end of the water channel 14 communicates with the flushing water channel 13 , and the bottom end communicates with the spray hole 115 . A water tank 3 is integrally formed at the rear of the toilet body, and the water outlet 31 of the water tank 3 communicates with the flushing channel 13 .

[0025] In this embodiment, the top ring of the bedpan 11 is provided with a water guiding ring 111 connected to the flushing ...

Embodiment 2

[0031] See Figure 4-Figure 6 As shown, the difference between the vortex water curtain type washing toilet of the present invention and the first embodiment is that the water guiding part 114 is located at the back side of the water guiding ring 111, and the two are connected front and back, and the water guiding part 114 A water hole 1142 with a diameter of about 8 mm is opened at the bottom of the portion 114 leading to the flushing channel 13 ; the upper edge portion 21 is located above the water guiding platform 1121 .

[0032] In this embodiment, the toilet body also includes a main body seat 1 and a seat panel 2, the main body seat 1 is provided with a bedpan 11 body, a sewage pipe 12, a flushing water channel 13 and the water tank 3, and the top ring of the bedpan 11 body is provided with guides. The water tank, the lower edge portion 112 ; the upper edge portion 21 is provided on the inner ring of the seat panel 2 . The seat ring panel 2 is bonded on the main body of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com