Double-component acrylate structure adhesive for bonding electrophoretic coating materials

An acrylic and electrophoretic coating technology, which is applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of unsatisfactory bonding strength and process requirements, unsatisfactory bonding effect of electrophoretic coatings, and electrophoretic coatings. Low surface energy characteristics of the coating, etc., to achieve good storage stability at room temperature, improve curing speed and adhesion, high peel strength and shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

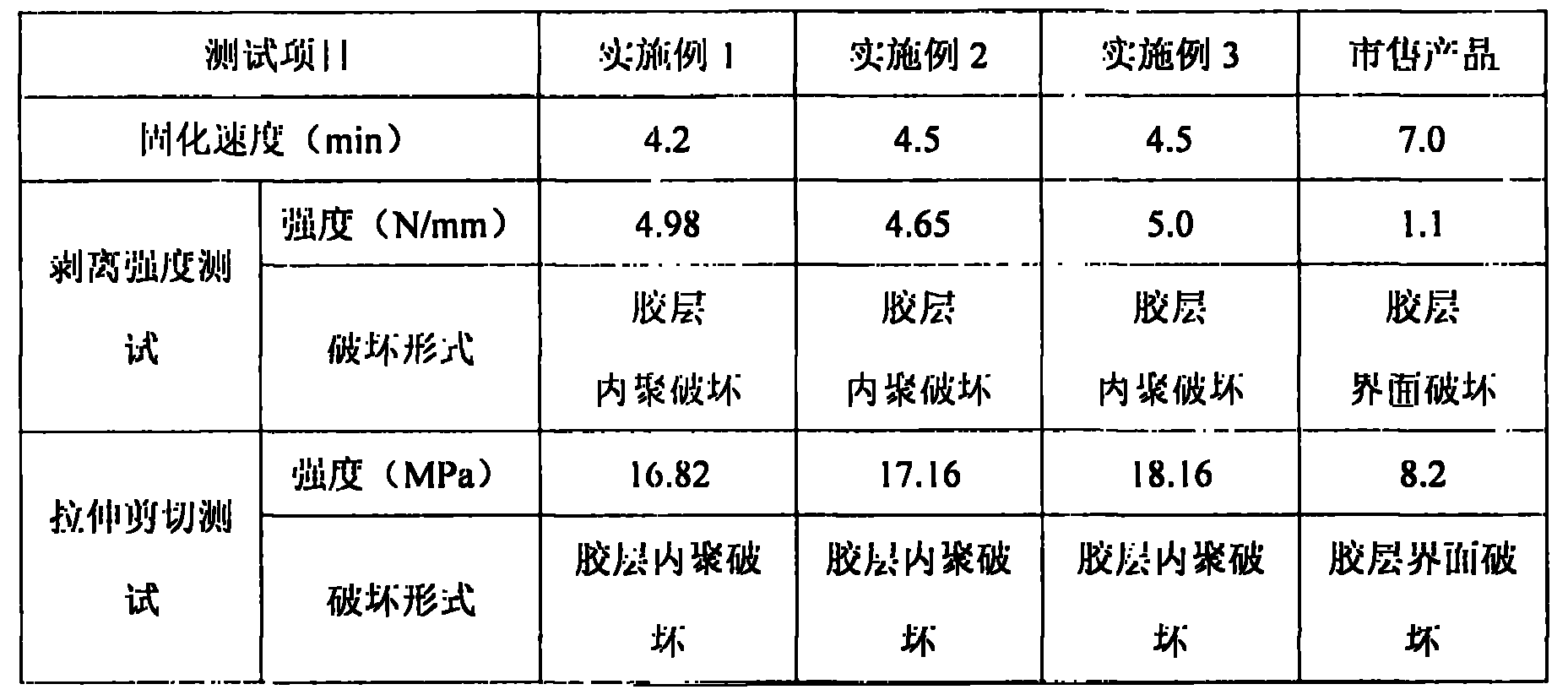

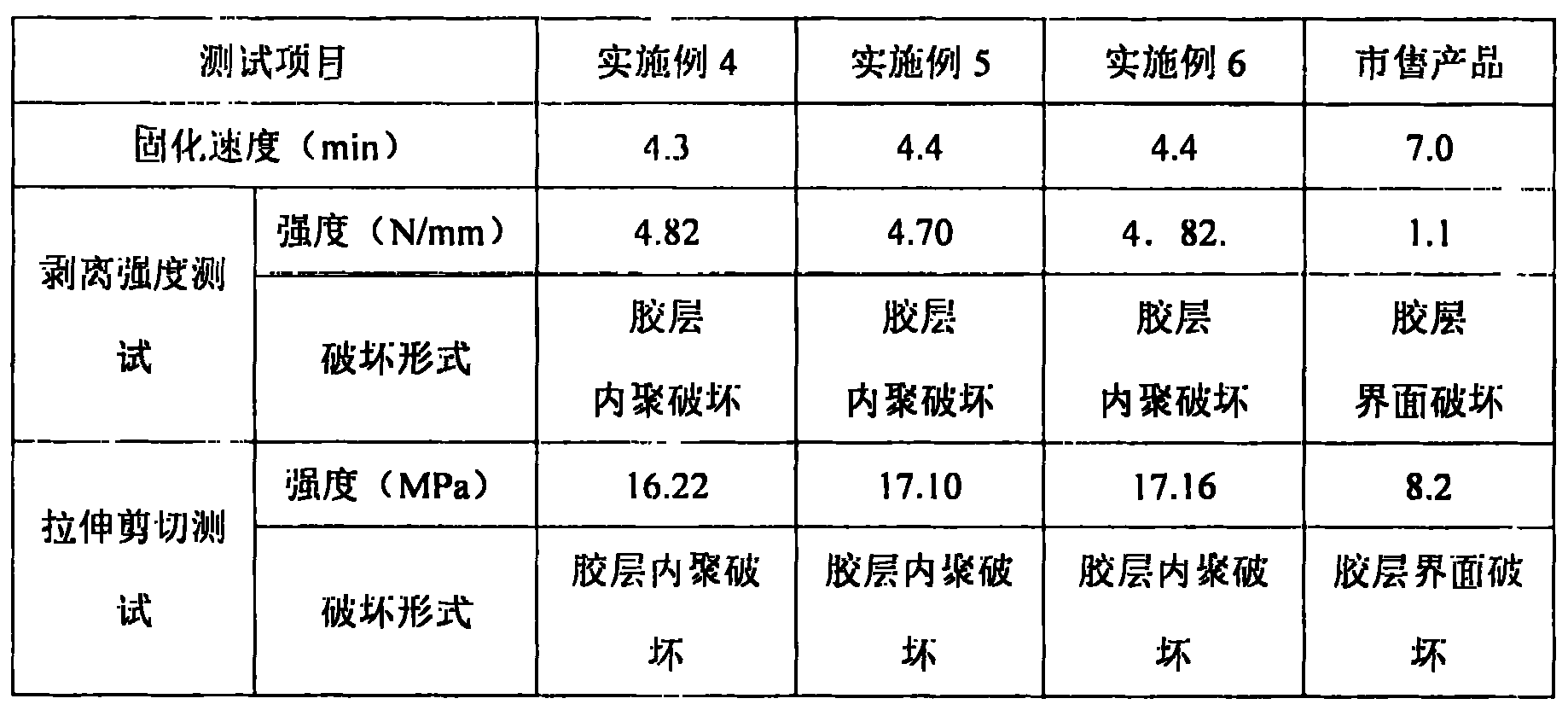

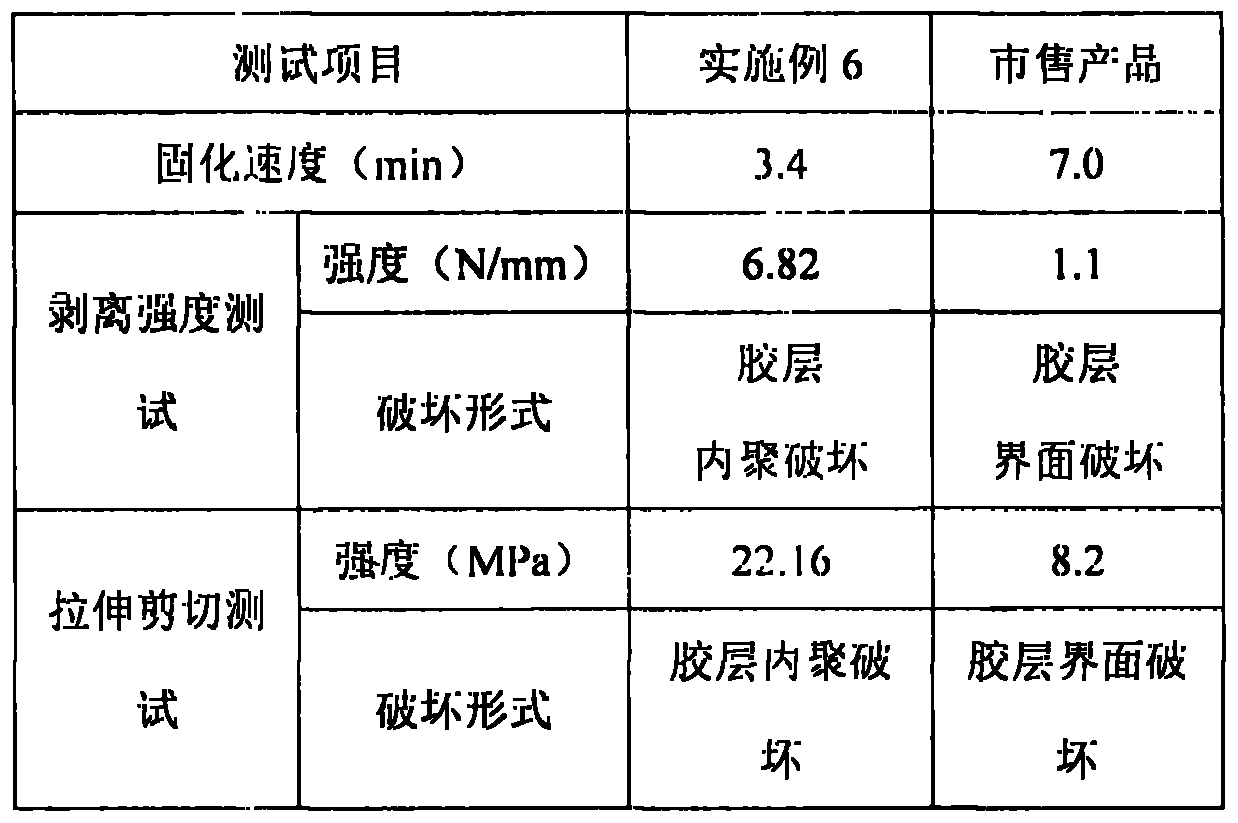

Examples

Embodiment 1

[0031] An acrylic structural adhesive, including component A and component B, in parts by mass, the components are as follows:

[0032] A component raw material

number of copies

45.95

Phenoxyethyl methacrylate

6

epoxy acrylate

10

8

liquid butadiene rubber

10

SIS resin

13

[0033] Polyethylene powder

5

2,6-di-tert-butyl-4-methylphenol

0.05

N,N-Dimethyl-p-toluidine

1

Paraffin

1

[0034] B component raw material

number of copies

30

40

27

2

iron blue

1

[0035] Preparation Process:

[0036] Preparation of component A: Accurately weigh methyl methacrylate, phenoxyethyl methacrylate, maleic acid, and epoxy acrylate and mix evenly; then mix SIS rubber, liquid butadiene r...

Embodiment 2

[0040] An acrylic structural adhesive, including component A and component B, in parts by mass, the components are as follows:

[0041] A component raw material

share

42

8

Ethylene glycol dimethacrylate

7

[0042] urethane acrylate

8

Nitrile rubber

10

liquid butadiene rubber

2

Benzyldimethylamine

2

PTFE powder

9.95

0.05

Paraffin

1

[0043] B component raw material

share

30

Bisphenol F epoxy resin

30

36

3

iron blue

1

[0044] Preparation Process:

[0045] Preparation of component A: Accurately weigh methyl methacrylate, methacrylic acid, ethylene glycol dimethacrylate, and urethane acrylate, and mix them evenly; then mix nitrile rubber, liquid butadiene rubber, and poly...

Embodiment 3

[0049] An acrylic structural adhesive, including component A and component B, in parts by mass, the components are as follows:

[0050] A component raw material

share

43

[0051] Methacrylate

7

1

Phenoxyethyl methacrylate

7

8

SBS

10

liquid butadiene rubber

12

N,N-Dimethyl-p-toluidine

1

PTFE powder

9.95

0.05

Paraffin

1

[0052] B component raw material

share

30

Bisphenol F epoxy resin

18

36

15

iron blue

1

[0053] Preparation Process:

[0054] Preparation of component A: Accurately weigh methyl methacrylate, methacrylic acid, phenoxyethyl methacrylate, phosphoric acid ester, and polyurethane acrylate, and mix well; then mix SBS, liquid but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com