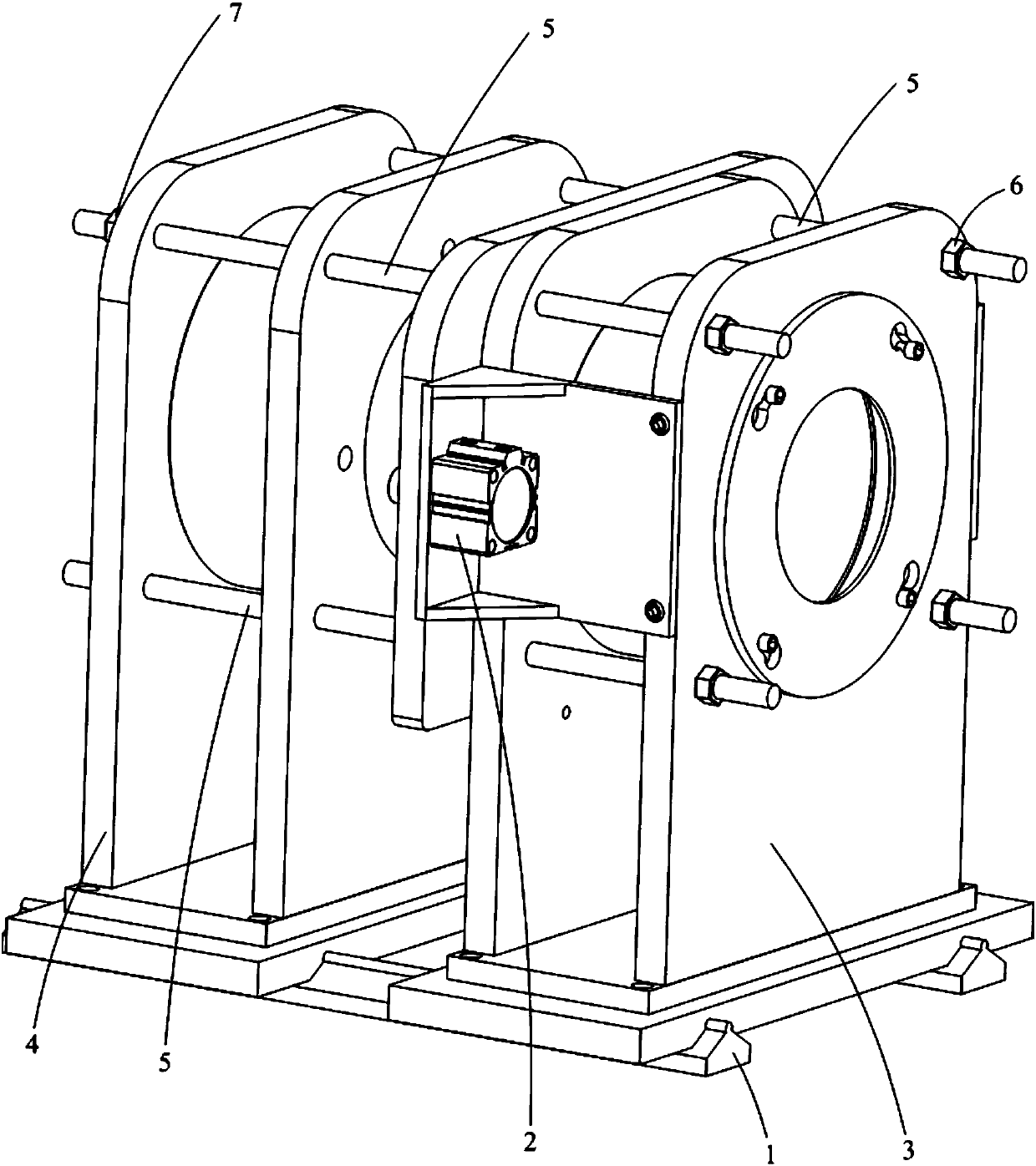

Patents

Literature

38results about How to "Guaranteed solid reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

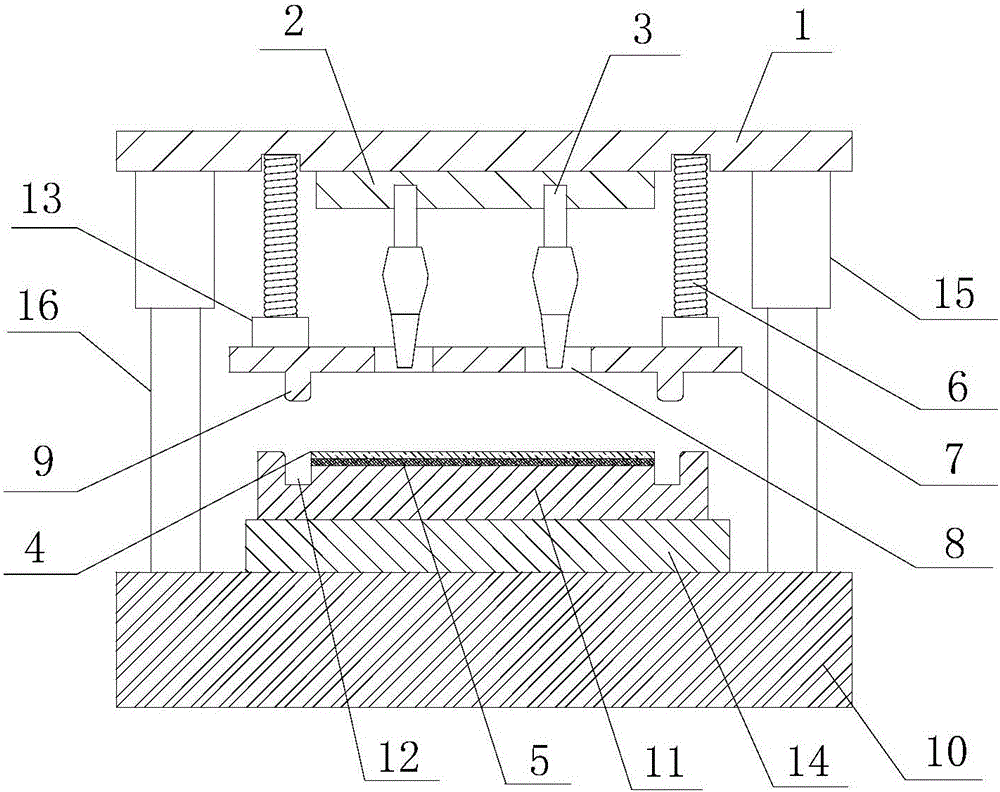

Welding press-fit mold

The invention discloses a welding press-fit mold, and relates to the technical field of plastic welding. The welding press-fit mold comprises an upper mold and a lower mold; the upper mold includes an upper mold base; a fixed plate is fixedly connected under the upper mold base; at least two ultrasonic welding heads are uniformly and fixedly connected under the fixed plate and are used for connecting a first plastic part and a second plastic part in a welding manner; an upper pressing plate is connected below the upper mold base through elastic pieces, and is provided with through holes through which the ultrasonic welding heads can penetrate; two limiting bars are symmetrically arranged on two sides of the upper pressing plate; the lower mold includes a lower mold base and a lower template fixed above the lower mold base; and limiting grooves matched with the limiting bars are formed in two sides of the top of the lower template. According to the welding press-fit mold, accurate positioning and firm pressing are achieved, and the problem that plastic parts are easily misplaced during welding is effectively avoided; and meanwhile, the at least two ultrasonic welding heads are adopted to uniformly contact with the plastic parts, so that the multi-point welding of the plastic parts is realized, the production procedures are greatly simplified, and the working efficiency is improved.

Owner:SUZHOU ANTONGLIN AUTOMOBILE INNER DECORATION CO LTD

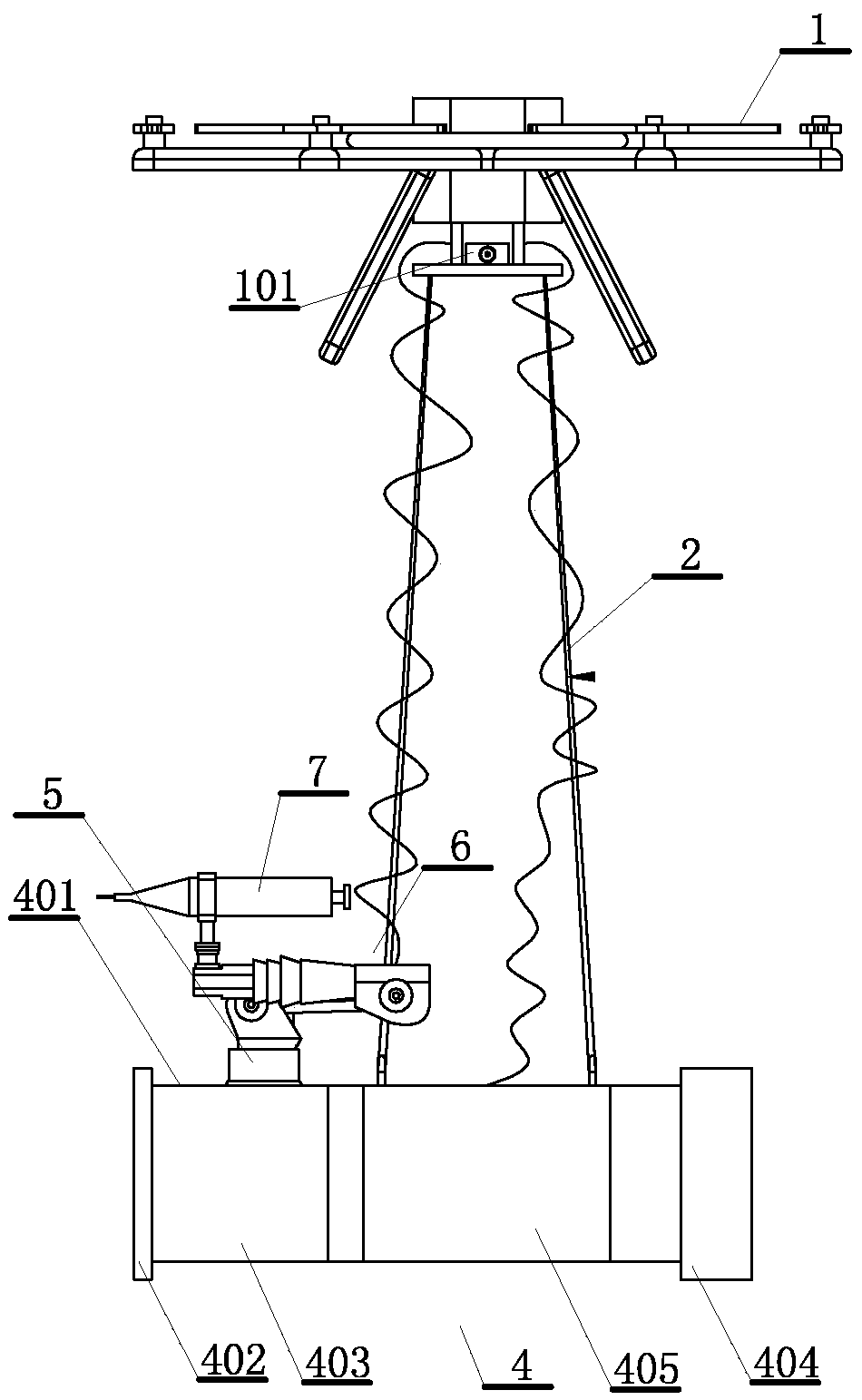

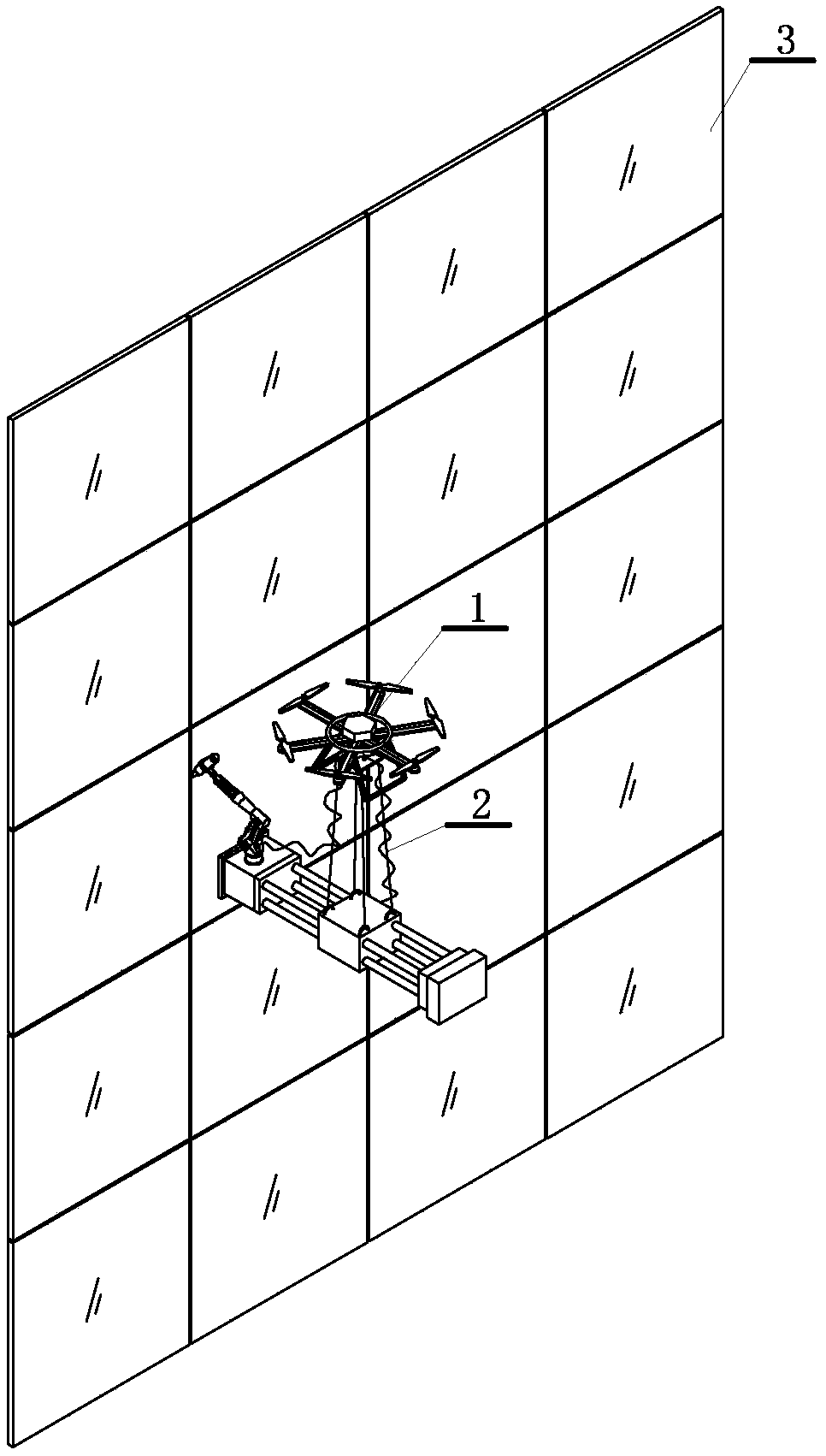

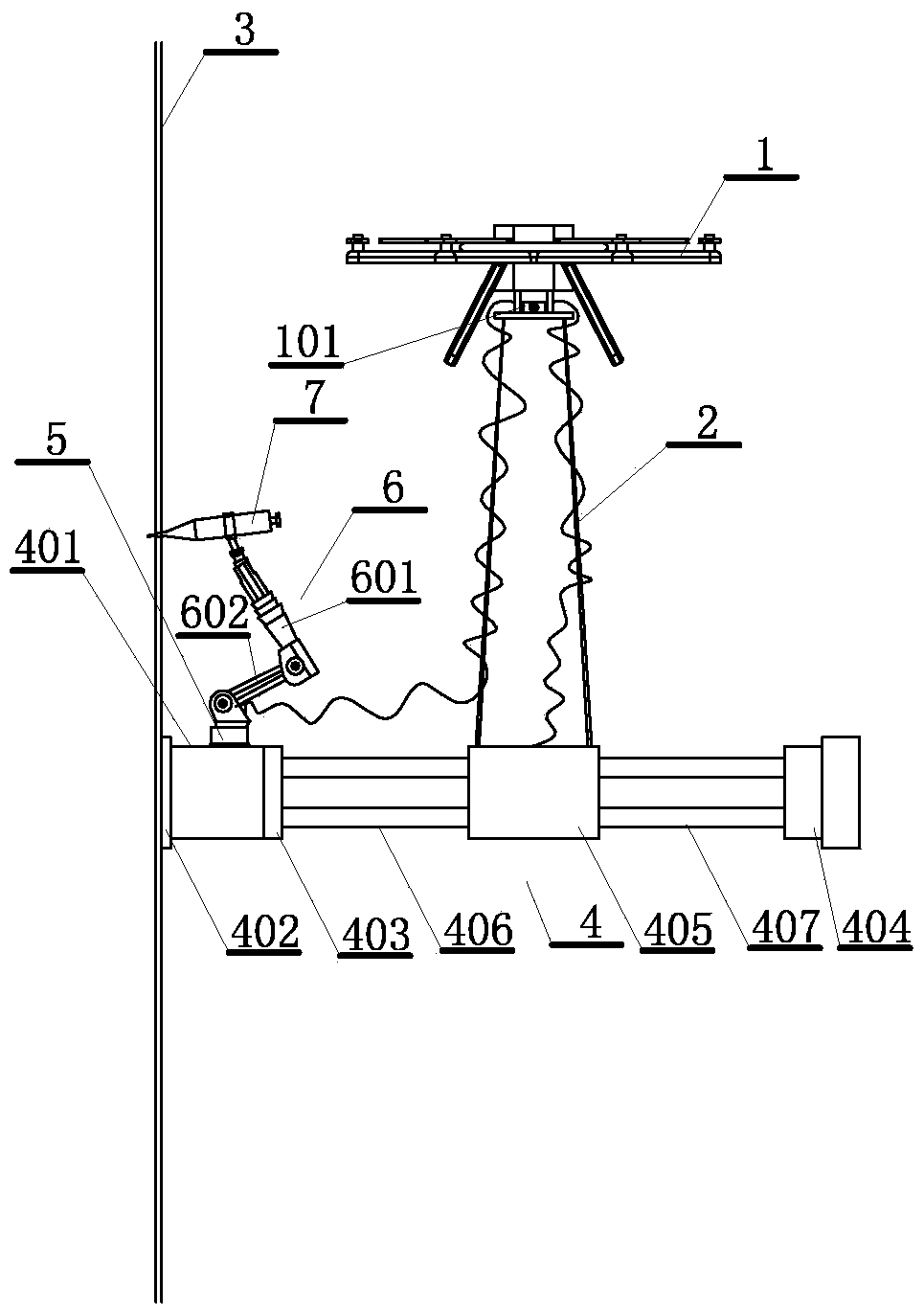

Aerial gluing robot for running maintenance of curtain wall and method thereof

PendingCN107618671AStable jobAvoid disadvantagesAircraft componentsLiquid surface applicatorsEngineeringHelicopter rotor

The invention discloses an aerial gluing robot for running maintenance of a curtain wall and a method thereof. The robot comprises a rotor wing unmanned aerial vehicle, a mechanical gluing machine issuspended on the rotor wing unmanned aerial vehicle through a rope and comprises a horizontal support frame, one end of the horizontal support frame is provided with a suckerperpendicular to a horizontal support frame upper-end platform, the sucker sideof the horizontal support frame upper-end platform is provided with a controllable horizontal rotating platform, the controllable horizontal rotating platform is provided with a controllable retractable arm, the controllable retractable arm can extend or retract vertically and horizontally, the top end of the controllable retractable arm is fixedly provided with a controllable gluing gun, and a wireless gluing controller controls the action of the mechanical gluing machine. According to the aerial gluing robot for the running maintenance ofthe curtain wall and the method thereof, water curtain treatment is additionally conducted between the sucker and the curtain wall so that the horizontal support frame can be firmly sucked to the curtain wall, the stable work of a glue injector is ensured, and unfavorable factors generated by normal recoiling force and tangential counter force in the glue injection process are avoided.

Owner:BEIJING JIAYU DOOR WINDOW & CURTAIN WALL JOINT STOCK

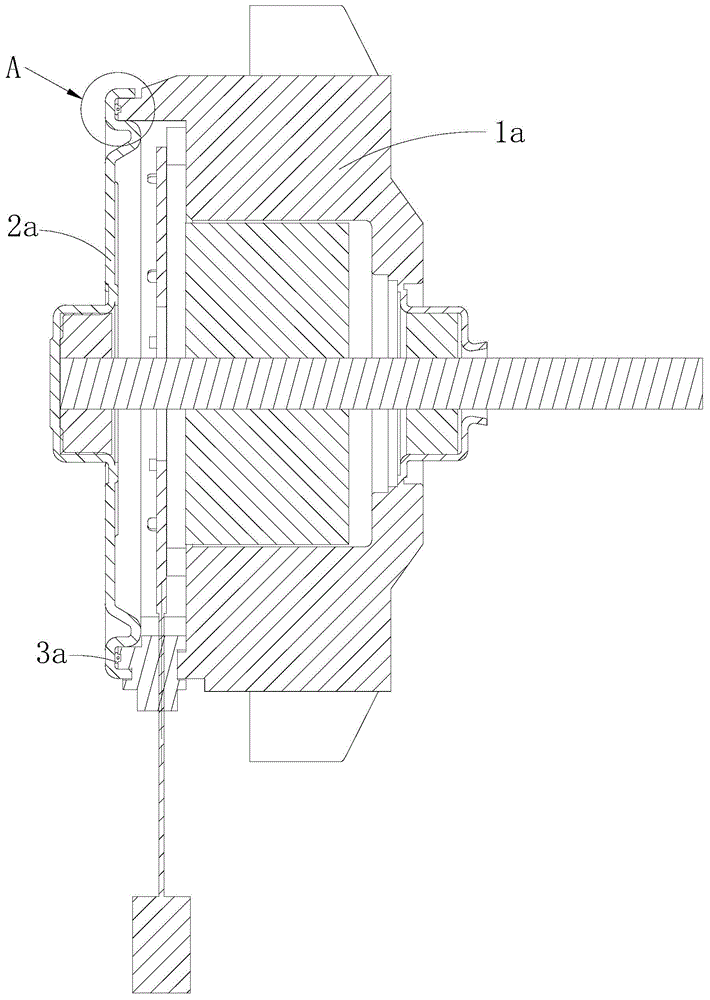

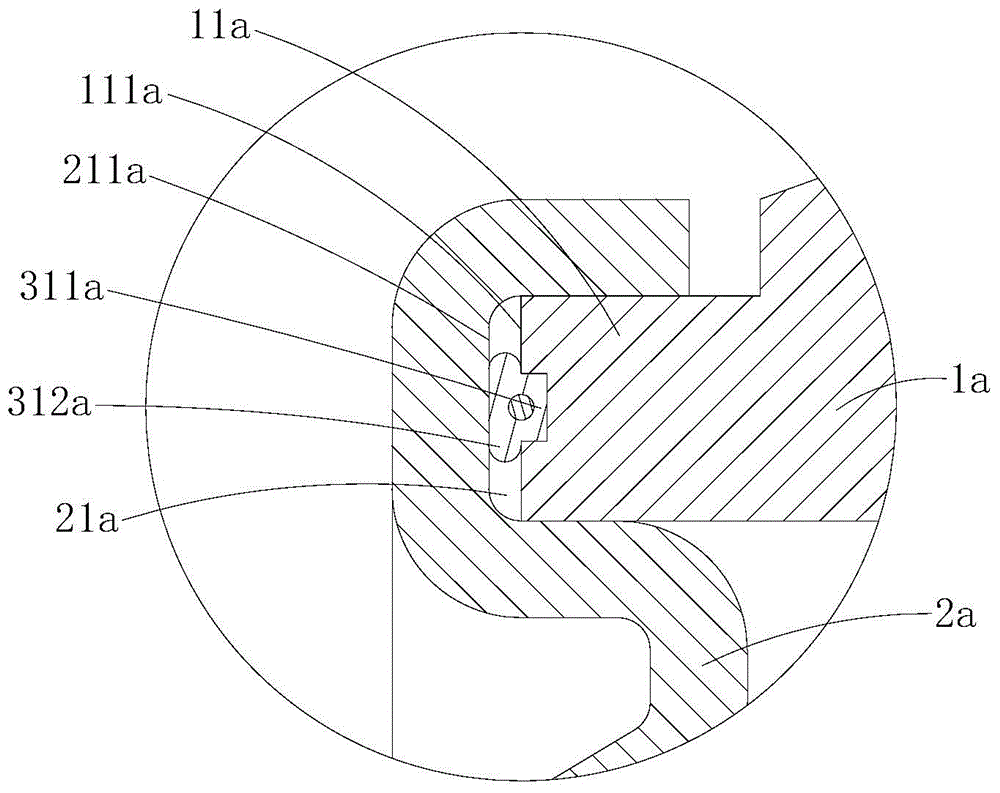

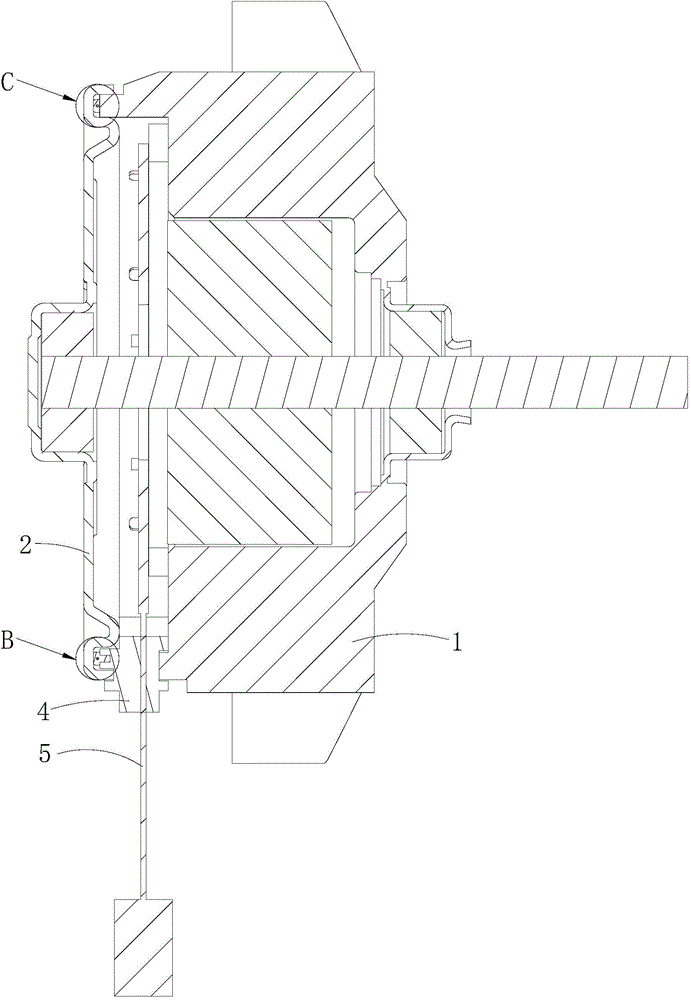

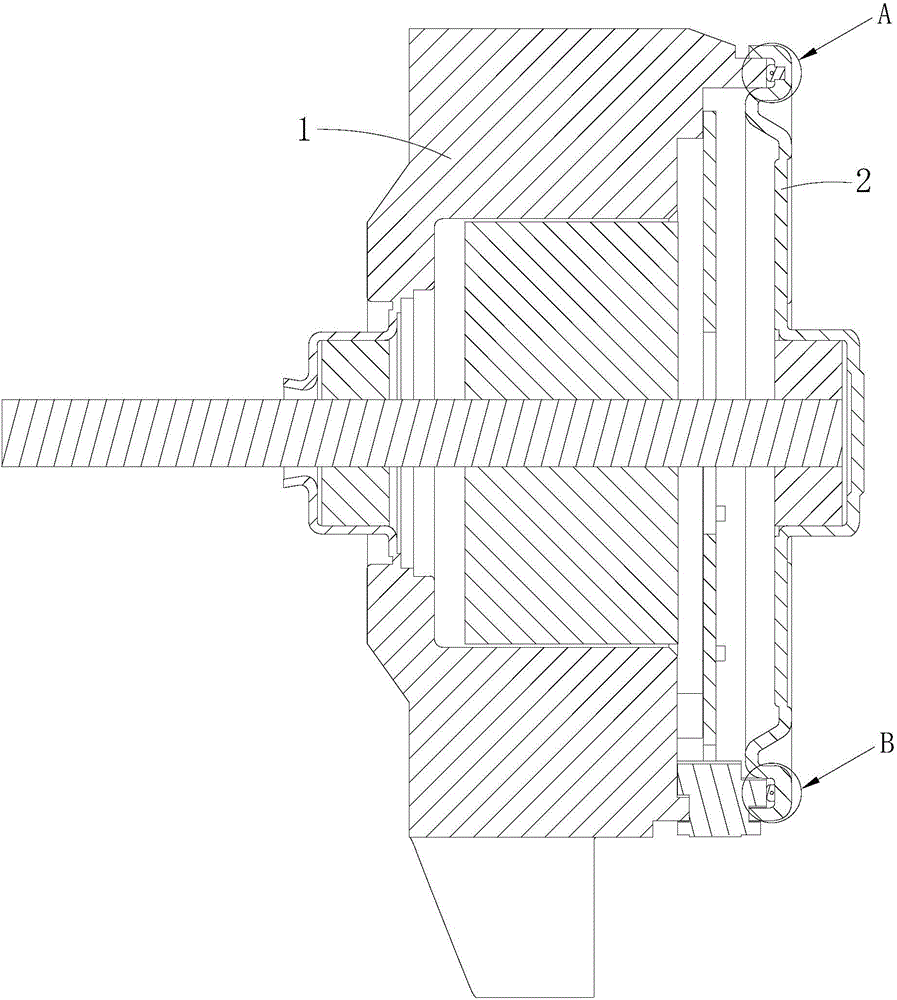

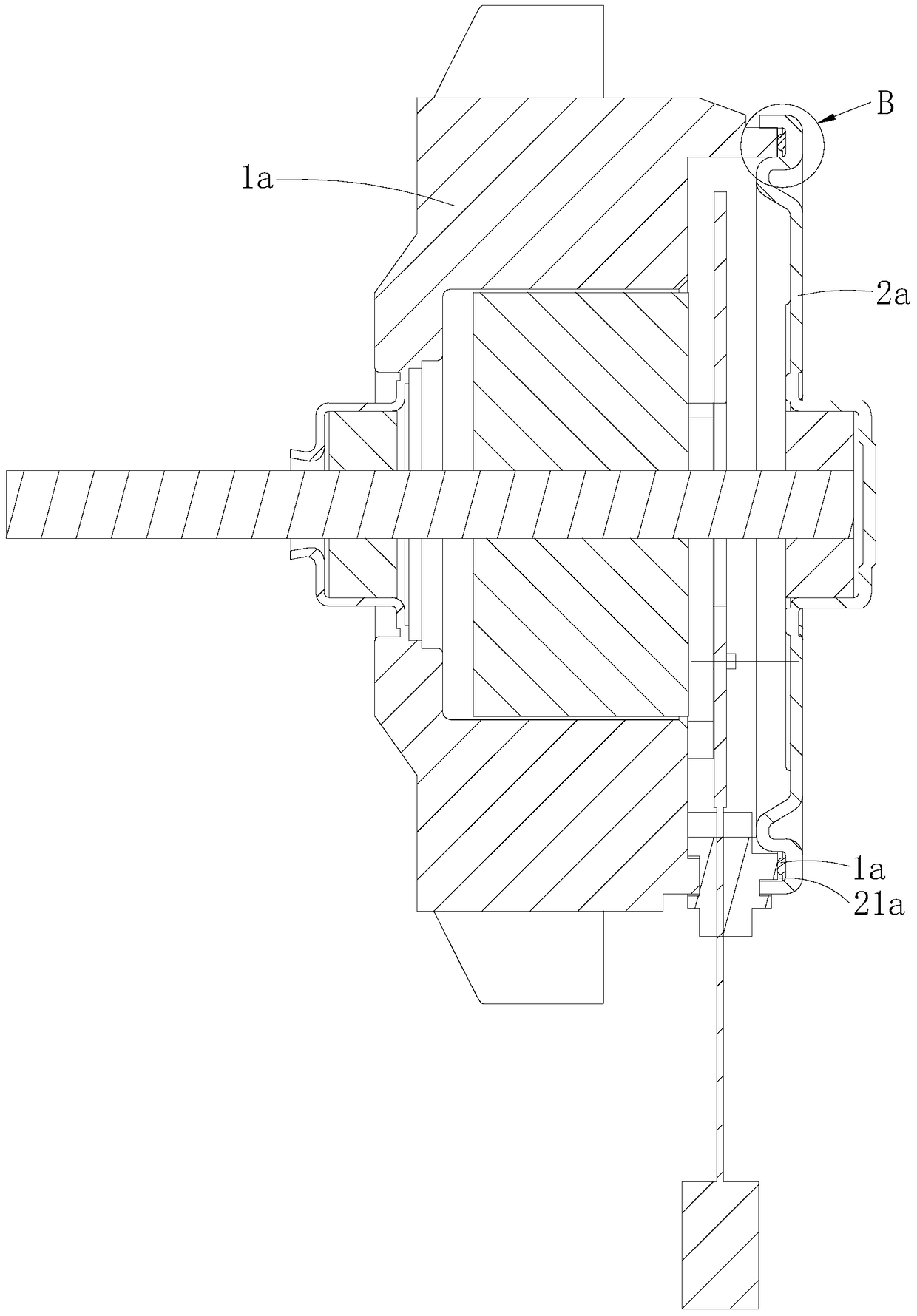

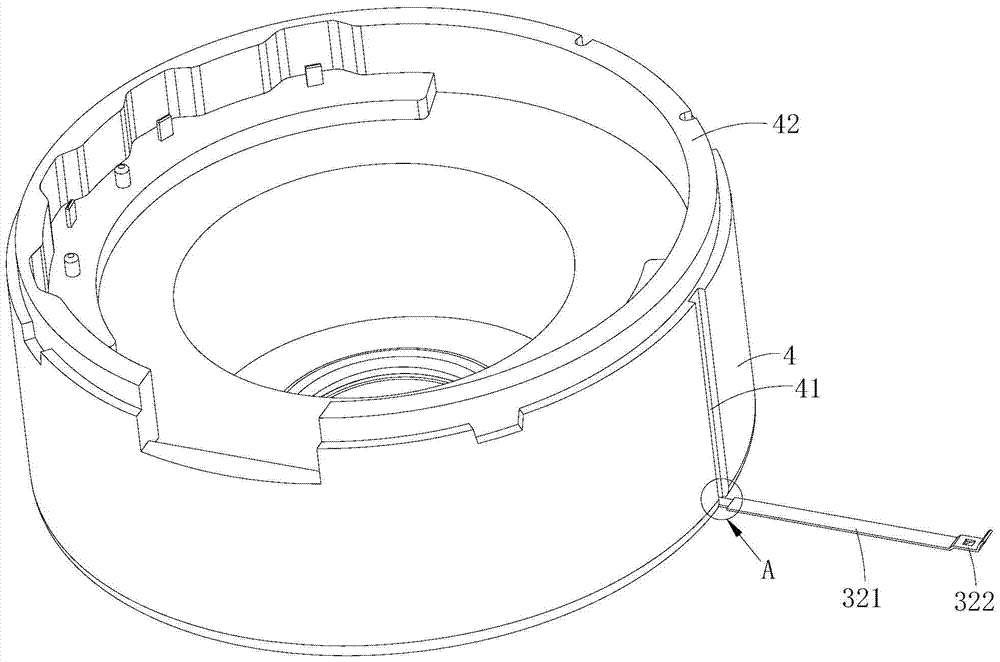

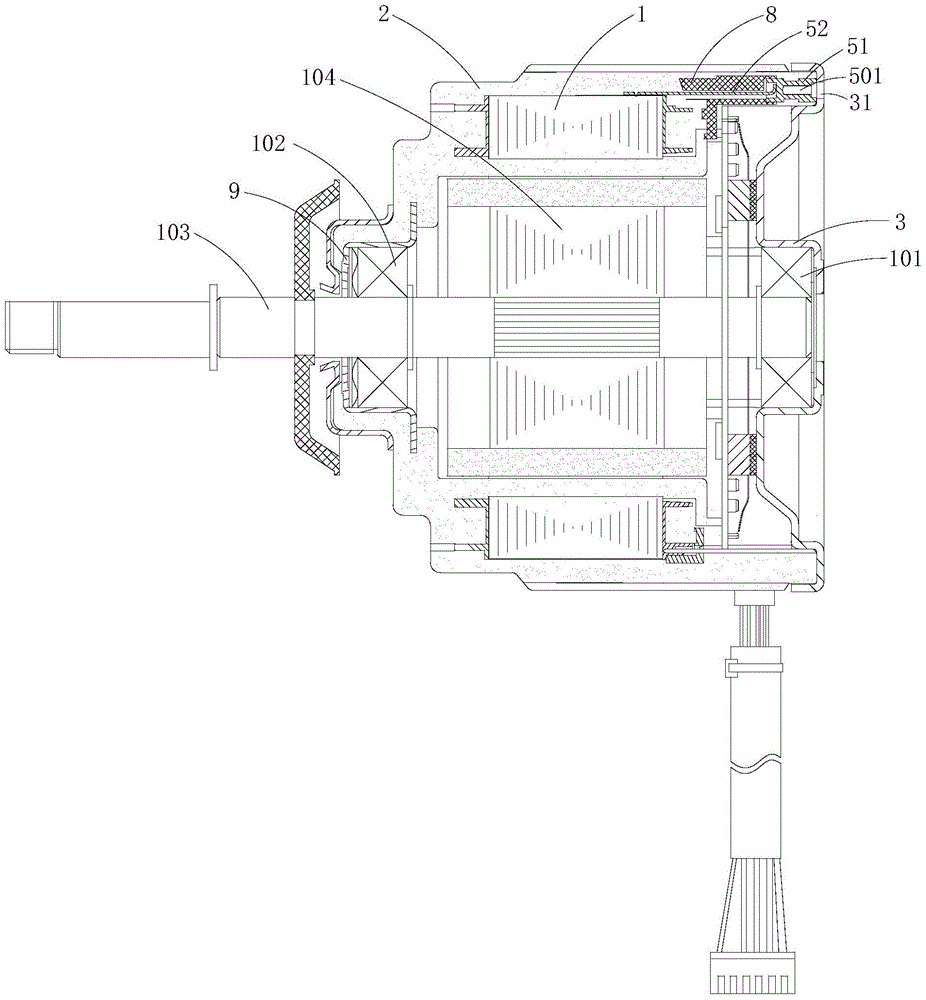

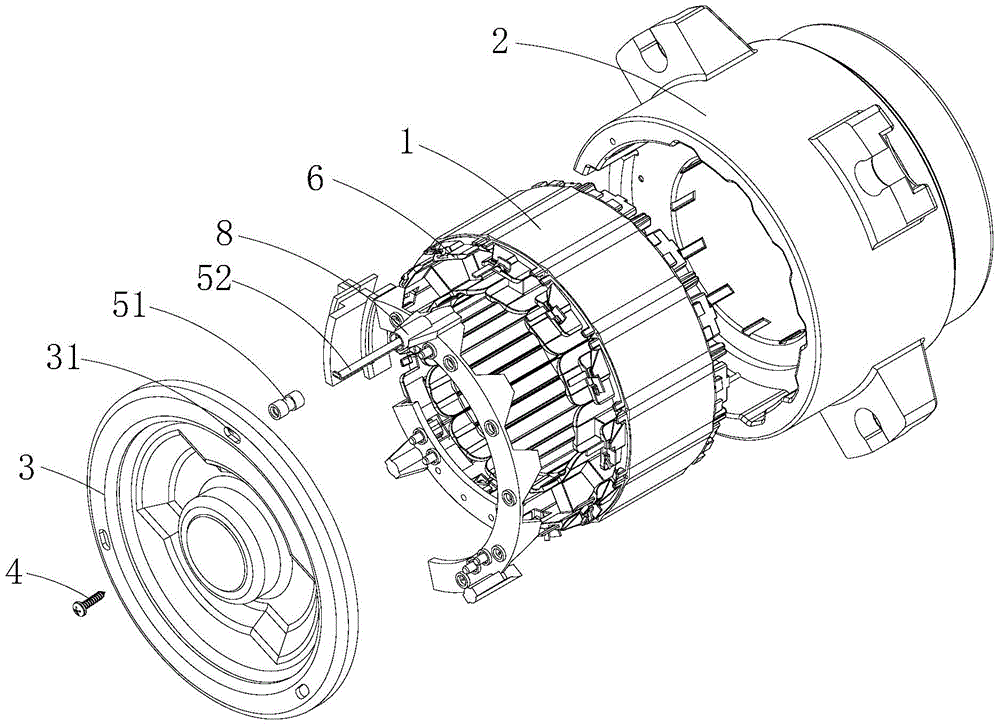

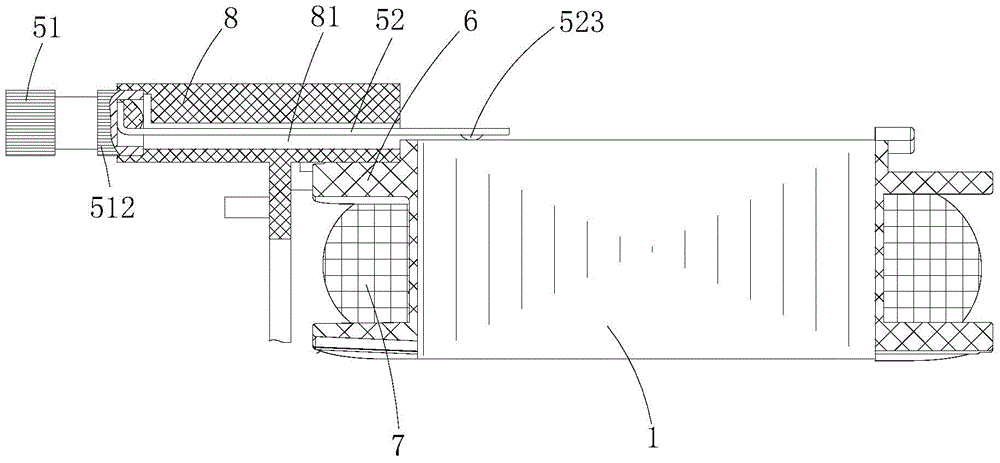

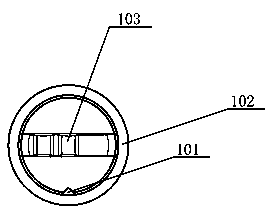

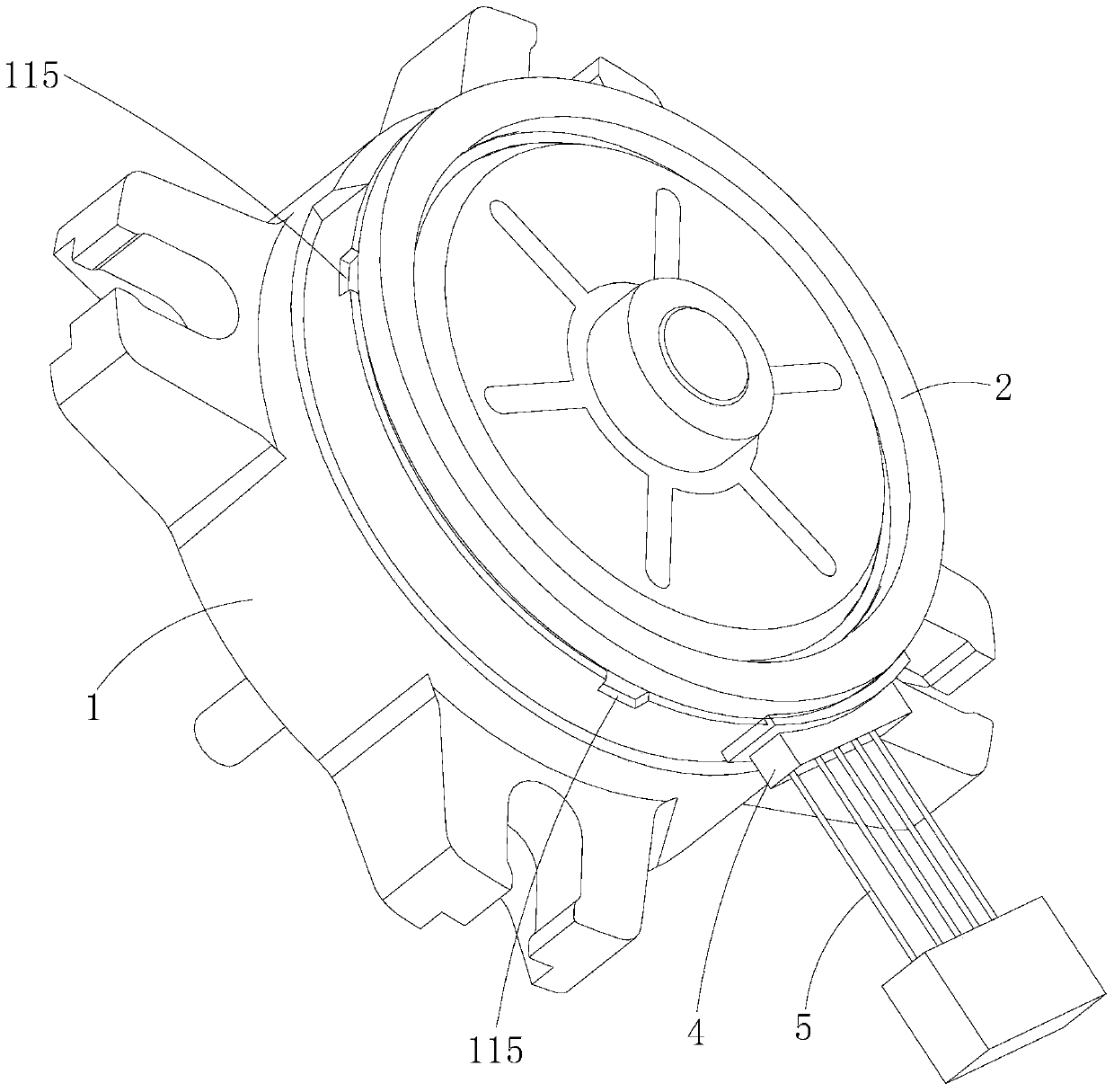

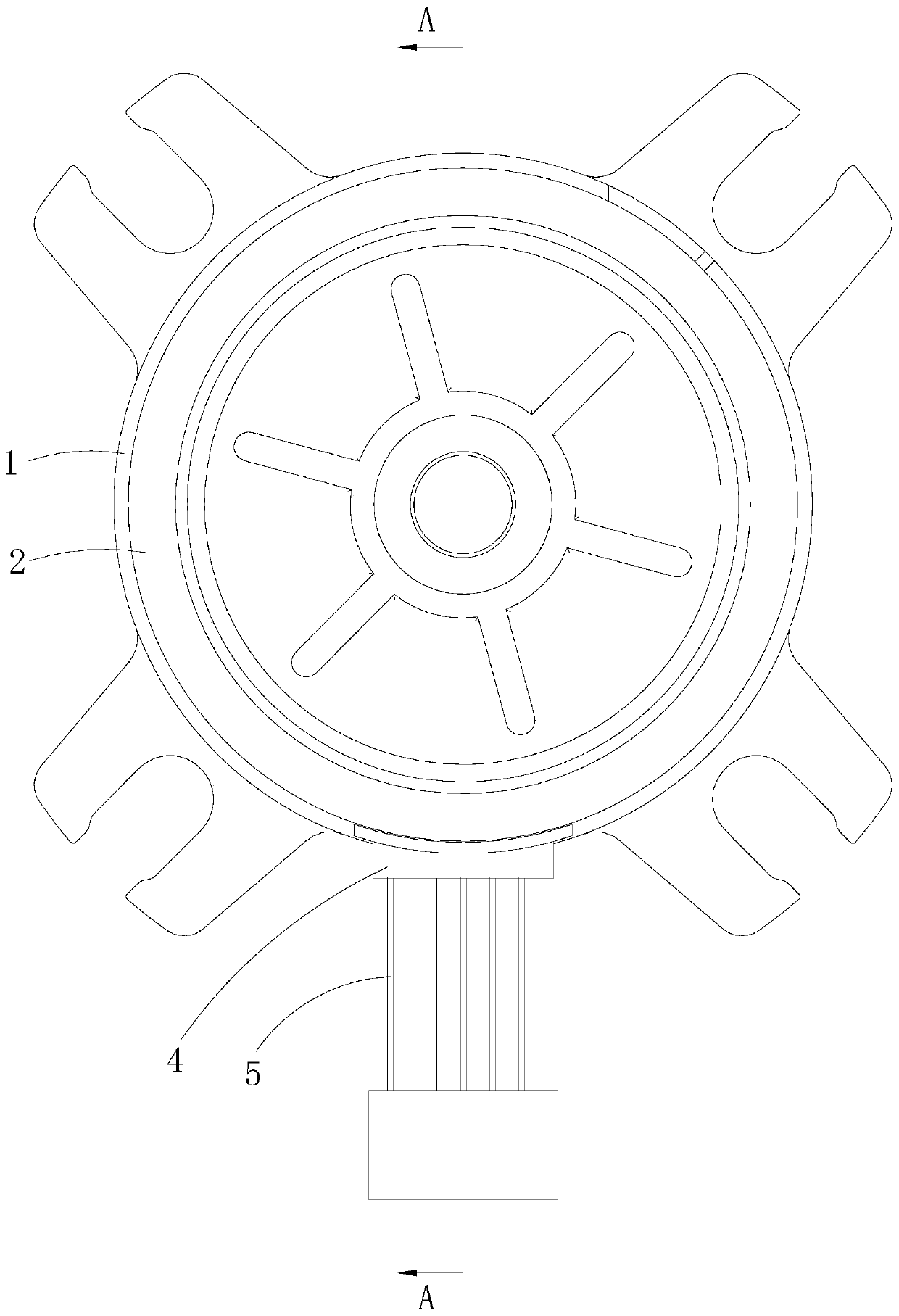

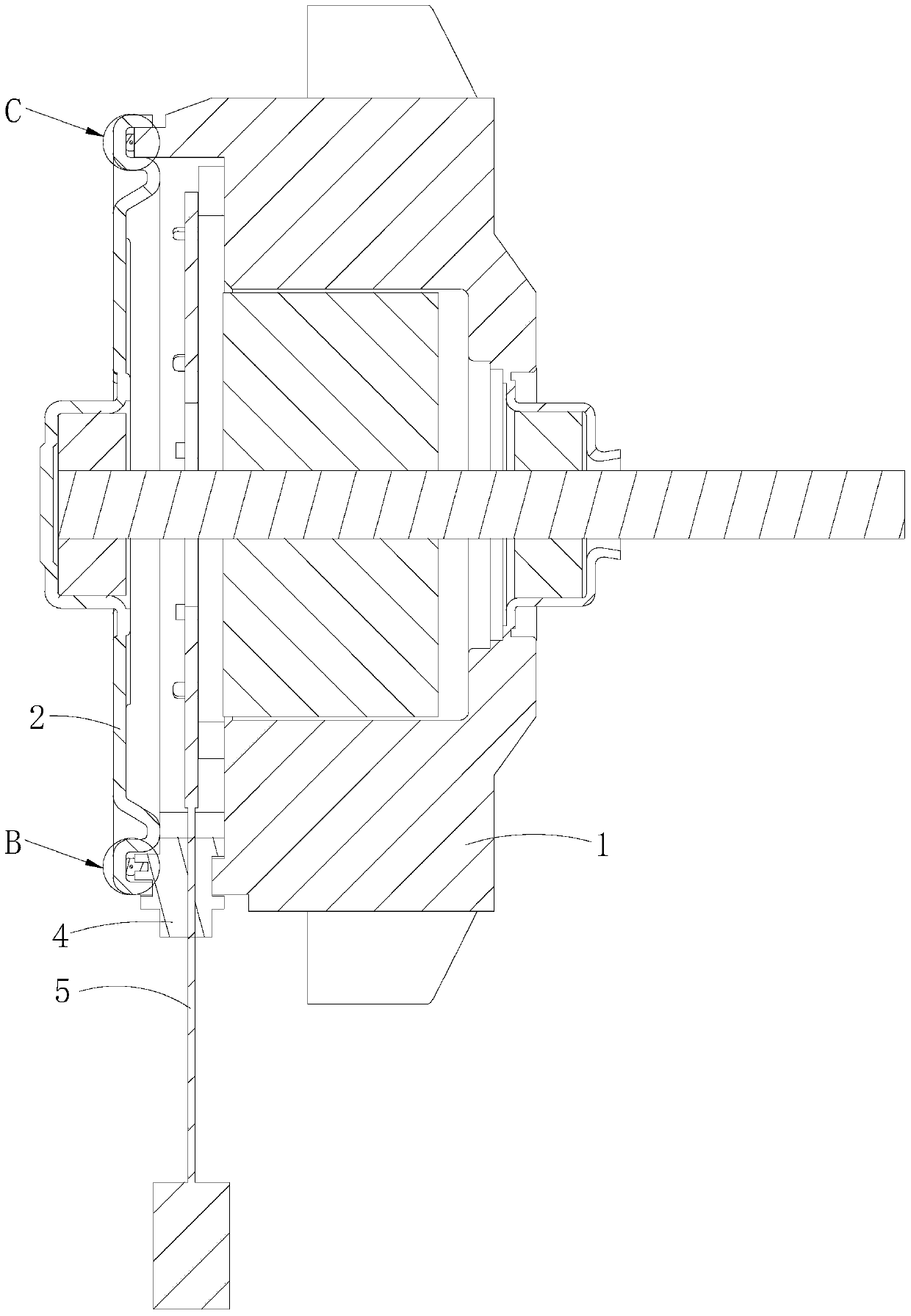

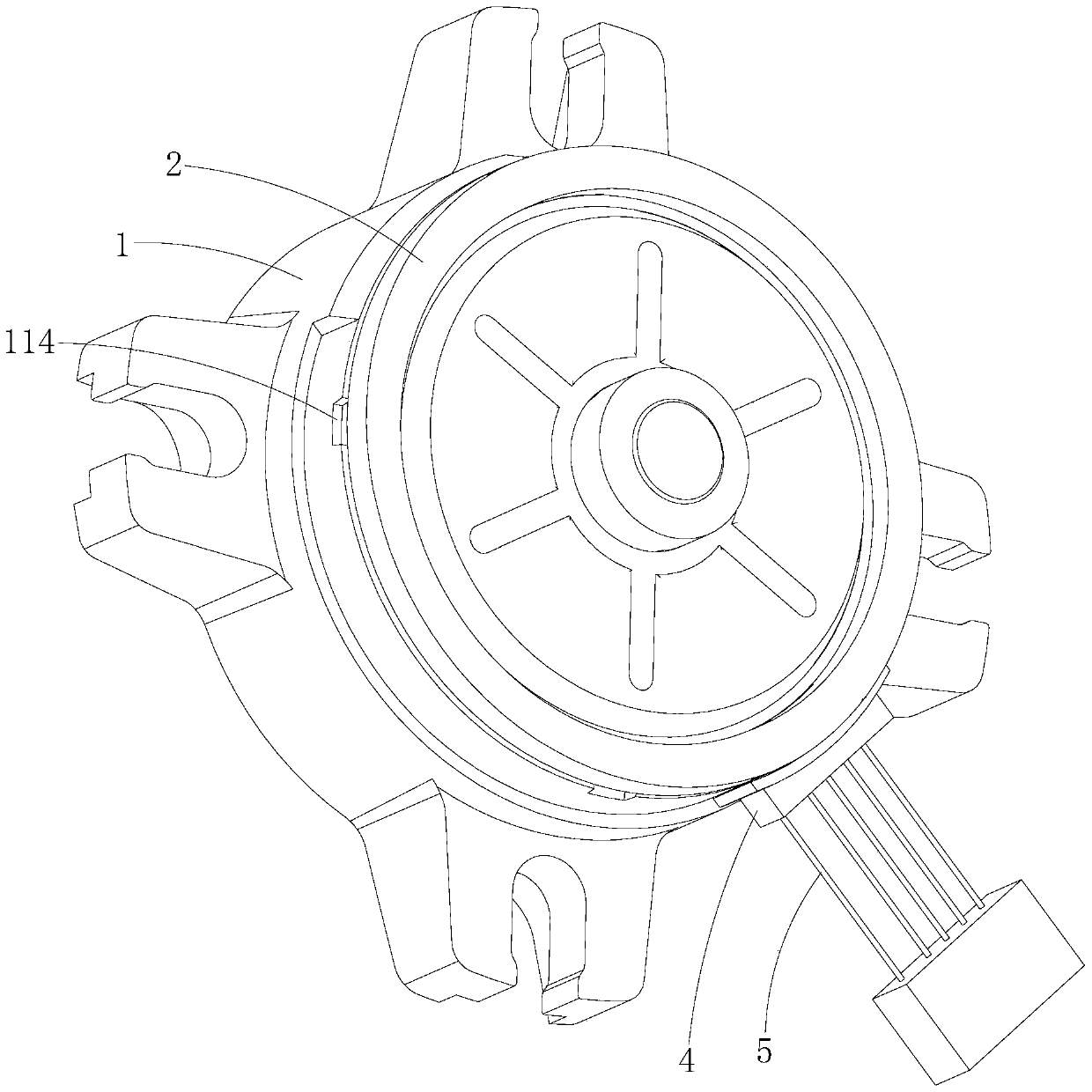

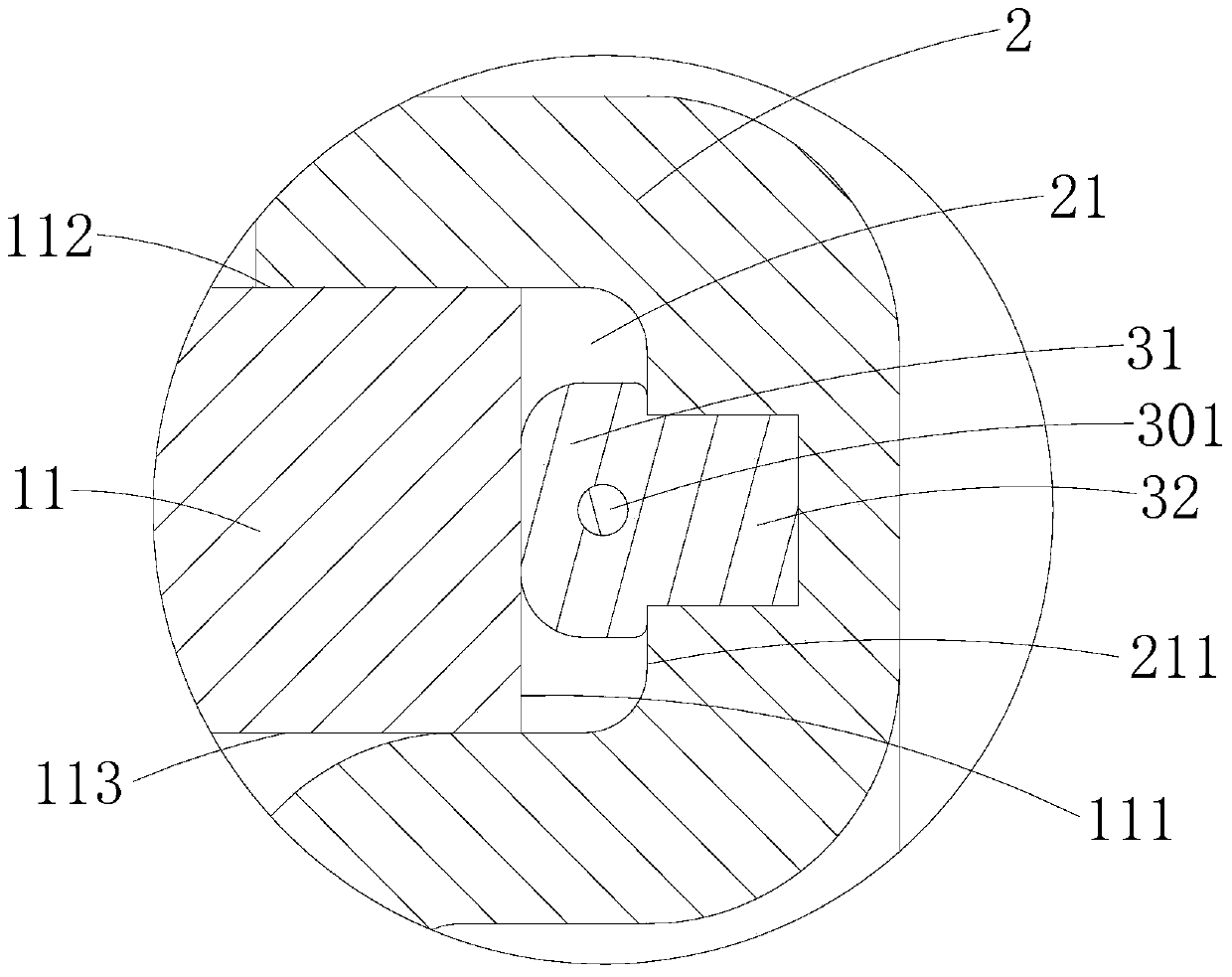

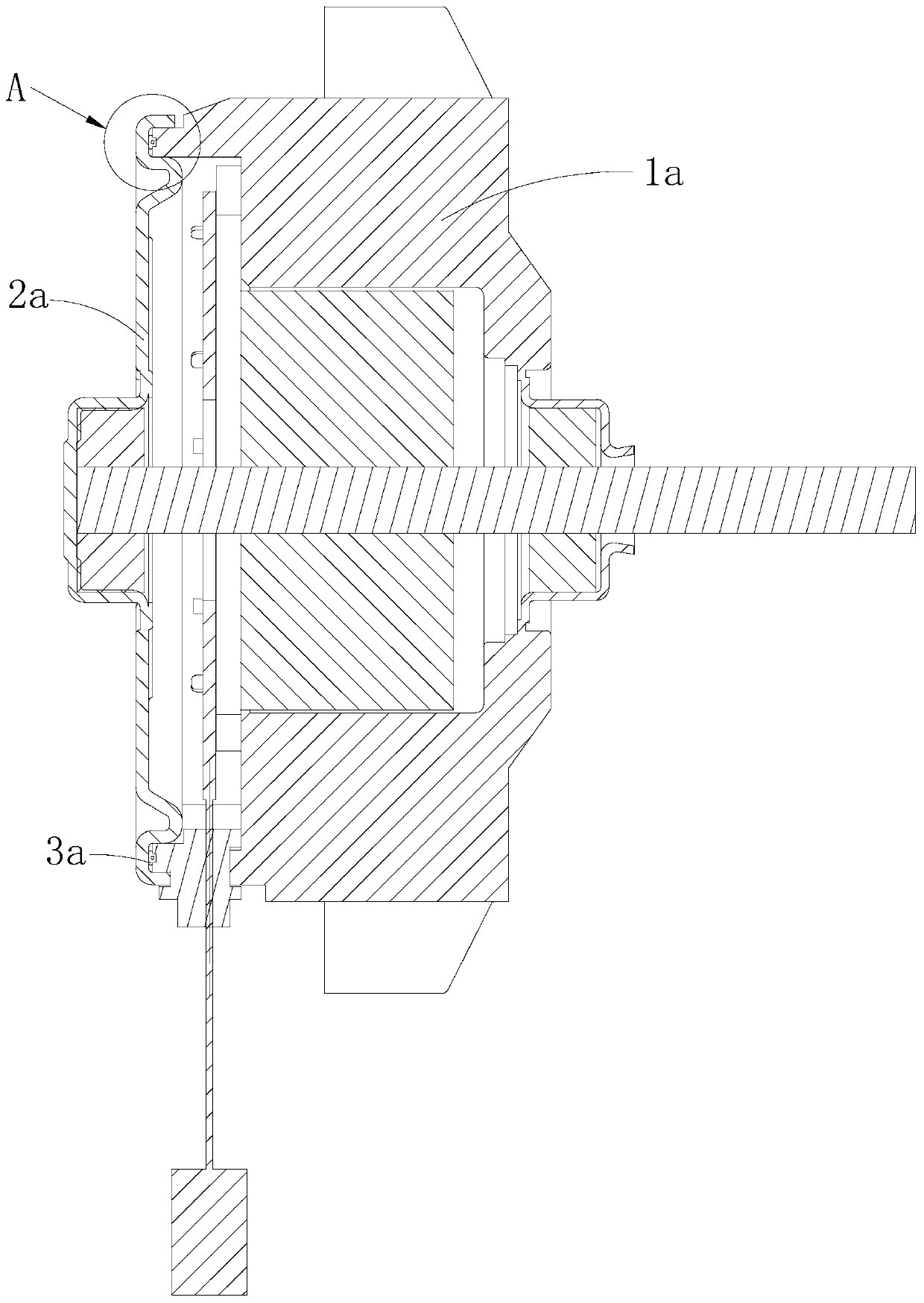

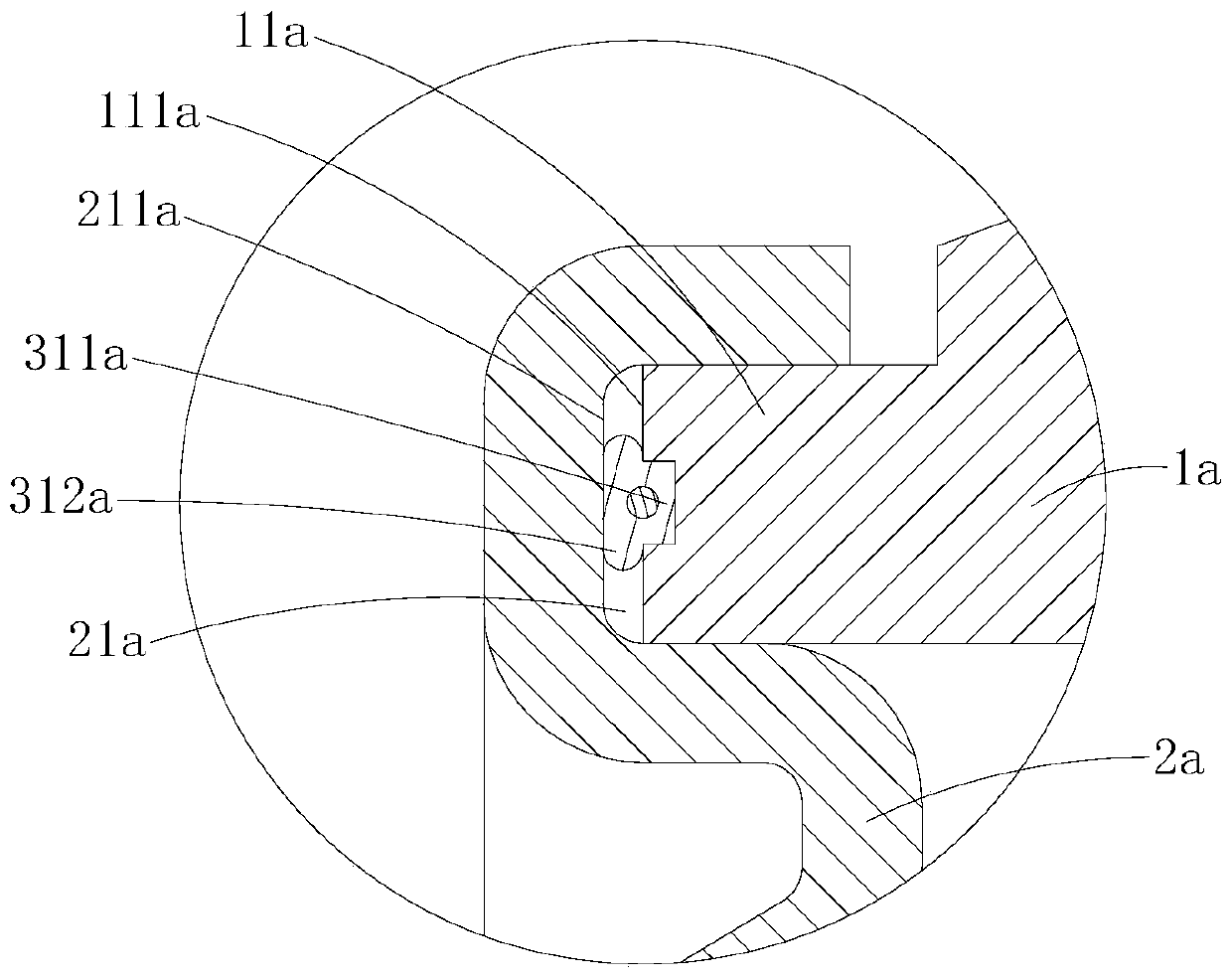

Plastic package stator and bearing end cap waterproof sealing structure and plastic package motor

ActiveCN104539081AGood waterproof and sealing performanceGuaranteed solid reliabilitySupports/enclosures/casingsEngineeringNeedle insertion

The invention relates to the field of motors, and discloses a plastic package stator and bearing end cap waterproof sealing structure and a plastic package motor. The plastic package stator and bearing end cap waterproof sealing structure comprises a plastic package stator, a bearing end cap and a waterproof sealing ring, wherein the plastic package stator is provided with an annular clamping flange, the bearing end cap is provided with an annular clamping groove matched with the annular clamping flange in a clamped and inserted mode, the annular clamping flange is provided with an axial end face towards the bearing end cap in the axial direction of the plastic package stator, the annular clamping groove is provided with a bottom groove face towards the plastic package stator in the axial direction of the plastic package stator, the waterproof sealing ring is elastically compressed between the axial end face and the bottom groove face, and a positioning groove allowing the waterproof sealing ring to be clamped, inserted and positioned is formed in the axial end face in a concave mode. The plastic package stator and bearing end cap waterproof sealing structure prevents influences of a needle insertion hole, a detection hole and a detachment notch which probably exist in the radial outer surface of the annular clamping flange on the sealing effect of the waterproof sealing ring, and achieves the aims of improving the waterproof sealing effect between the plastic package stator and the bearing end cap.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Plastic package stator and bearing end cap waterproof sealing structure and plastic package motor

ActiveCN104539080AGood waterproof and sealing performanceGuaranteed solid reliabilitySupports/enclosures/casingsEngineeringFace flush

The invention relates to the field of motors, and discloses a plastic package stator and bearing end cap waterproof sealing structure and a plastic package motor. The plastic package stator and bearing end cap waterproof sealing structure comprises a plastic package stator, a wire retaining clip, a waterproof sealing ring and a bearing end cap, wherein the plastic package stator is provided with an annular clamping flange with an installation notch, the wire retaining clip is installed in the installation notch, the bearing end cap is provided with an annular clamping groove matched with the annular clamping flange in a clamped and inserted mode, the annular clamping flange is provided with an axial end face, the wire retaining clip is provided with a wire clip top face flush with the axial end face, the annular clamping groove is provided with a bottom groove face, the waterproof sealing ring is elastically compressed between the axial end face and the bottom groove face, and a positioning groove allowing the waterproof sealing ring to be clamped and positioned is formed in the wire clip top face in a concave mode. The plastic package stator and bearing end cap waterproof sealing structure prevents influences of a needle insertion hole, a detection hole and a detachment notch which probably exist in the radial outer surface of the annular clamping flange on the sealing effect of the waterproof sealing ring, and achieves the aims of improving the waterproof sealing effect between the plastic package stator and the bearing end cap.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

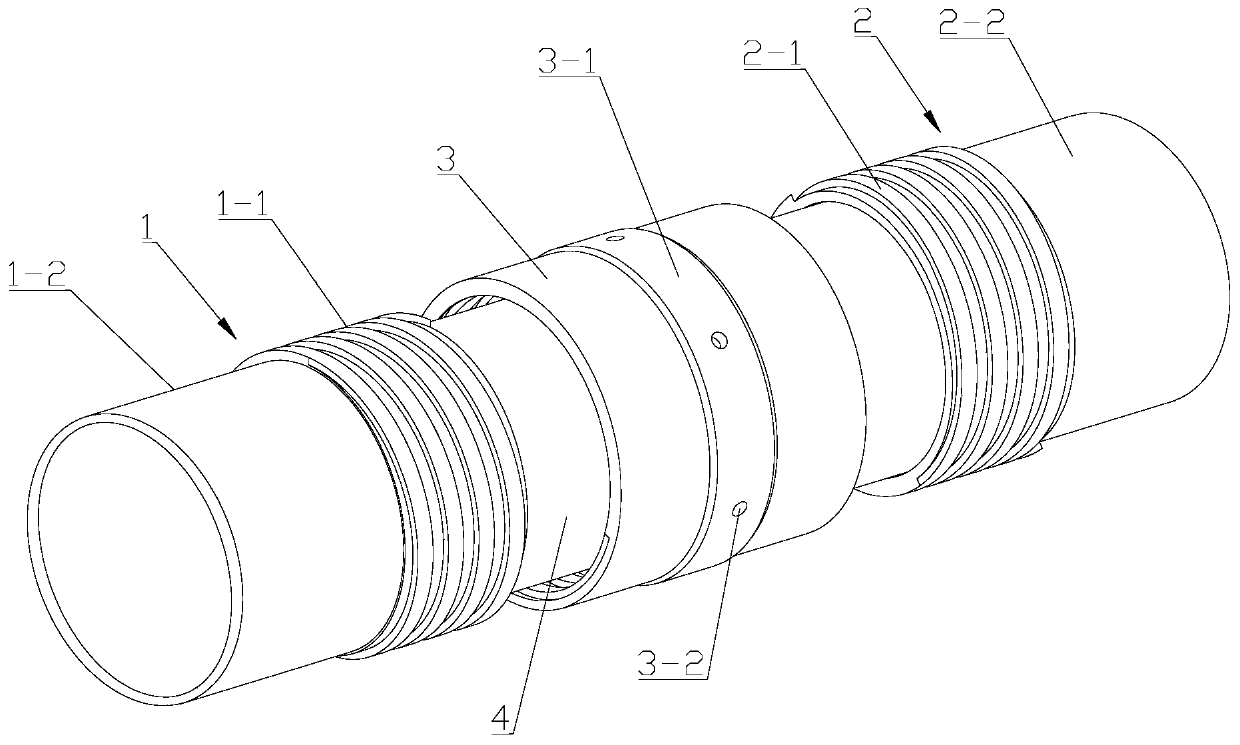

Detectable attachment joint for carbon fiber composite material pipes and application method of detectable attachment joint

PendingCN110778579AFirmly connectedIntegrity guaranteedMaterial gluingRod connectionsPipe fittingFibrous composites

The invention discloses a detectable attachment joint for carbon fiber composite material pipes and an application method of the detectable attachment joint. The detectable attachment joint comprisesa left joint body and a right joint body. The outer side of the left joint body is in fastening connection with the outer side of the right joint body through an outer clamping sleeve joint, the innerside of the left joint body is in fastening connection with the inner side of the right joint body through an inner insertion pipe, the right end of the left joint body is provided with a left spiralouter thread, the left end of the right joint body is provided with a right spiral outer thread, and the left and right ends of the outer clamping sleeve joint are provided with inner threads. The method comprises the steps of step 1, roughening the surfaces of pipe fittings; step 2, gluing the carbon fiber composite material pipes and the attachment joint; step 3, connecting the carbon fiber composite material pipes. The detectable attachment joint is reasonable in structural design, the method is simple in step, the left joint body and the right joint body are arranged on the two carbon fiber composite material pipes respectively, the inner insertion pipe and the outer clamping sleeve joint are connected to the interiors and exteriors of the left joint body and the right joint body respectively, so that the carbon fiber composite material pipes are fixedly connected, and the connection efficiency and strength can be effectively improved.

Owner:XIAN KANGBEN MATERIAL

Plastic package stator and bearing end cap waterproof sealing structure and plastic package motor

ActiveCN104539082AEasy to movePromote sheddingSupports/enclosures/casingsEngineeringNeedle insertion

The invention relates to the field of motors, and discloses a plastic package stator and bearing end cap waterproof sealing structure and a plastic package motor. The plastic package stator and bearing end cap waterproof sealing structure comprises a plastic package stator, a bearing end cap and a waterproof sealing ring between the plastic package stator and the bearing end cap, wherein the plastic package stator is provided with an annular clamping flange, the bearing end cap is provided with an annular clamping groove matched with the annular clamping flange in a clamped and inserted mode, the annular clamping flange is provided with an axial end face towards the bearing end cap in the axial direction of the plastic package stator, the annular clamping groove is provided with a bottom groove towards the plastic package stator in the axial direction of the plastic package stator, the waterproof sealing ring is elastically compressed between the axial end face and the bottom groove face, and a positioning hole allowing the waterproof sealing ring to be clamped and positioned is formed in the bottom groove face in a concave mode. The plastic package stator and bearing end cap waterproof sealing structure prevents influences of a needle insertion hole, a detection hole and a detachment notch which probably exist in the radial outer surface of the annular clamping flange on the sealing effect of the waterproof sealing ring, and achieves the aims of improving the waterproof sealing effect between the plastic package stator and the bearing end cap.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

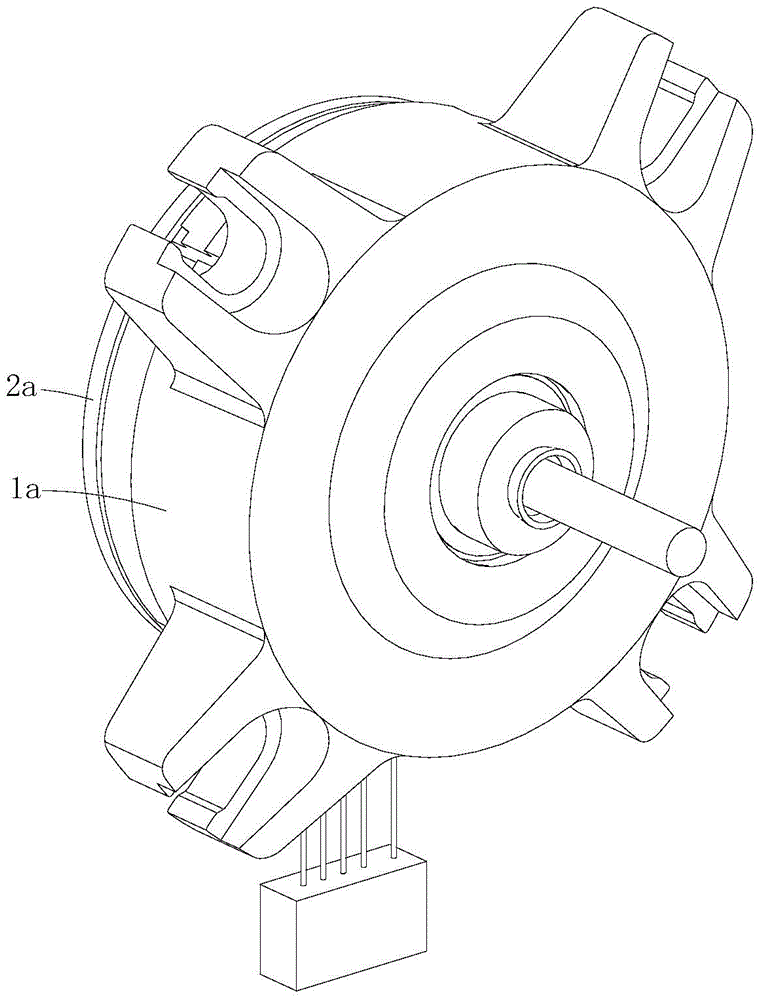

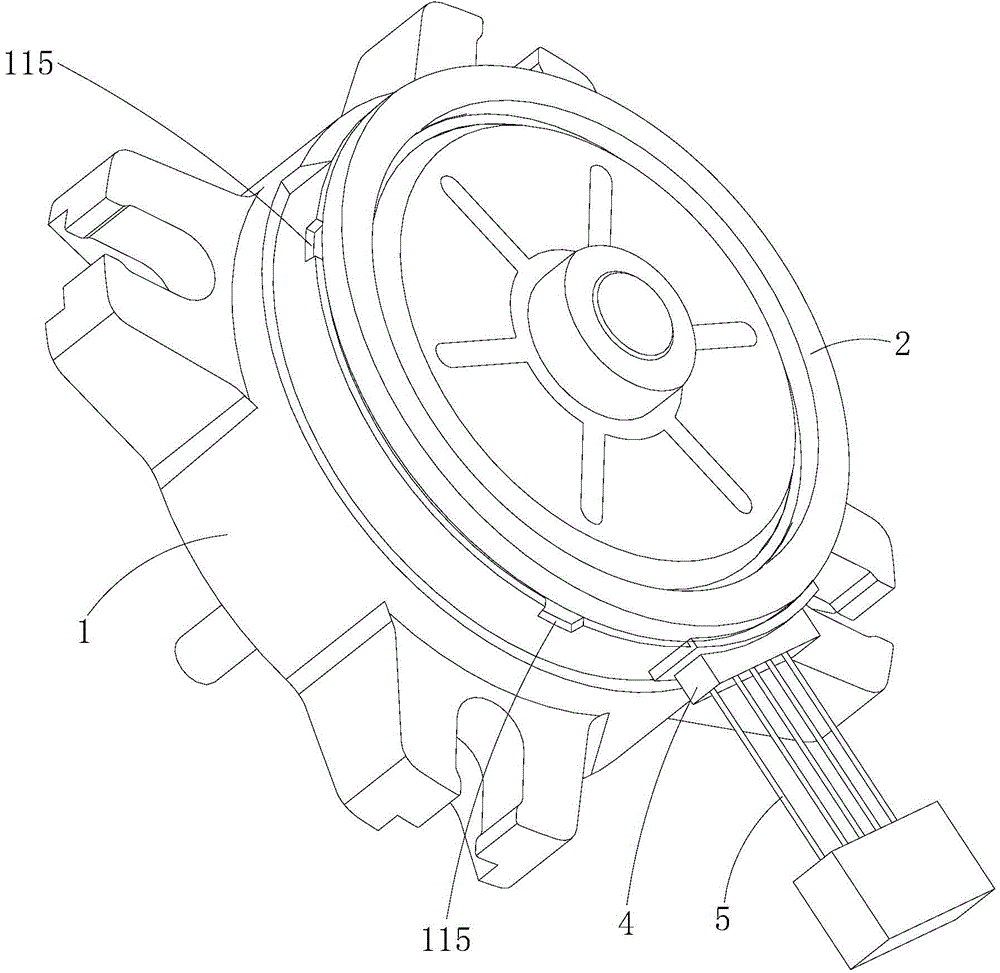

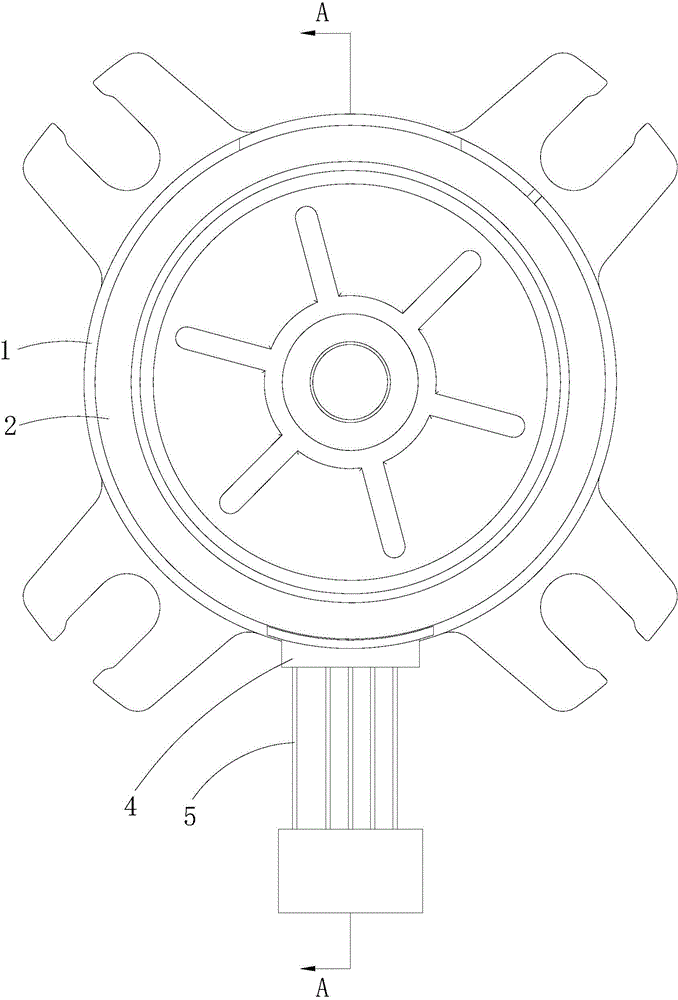

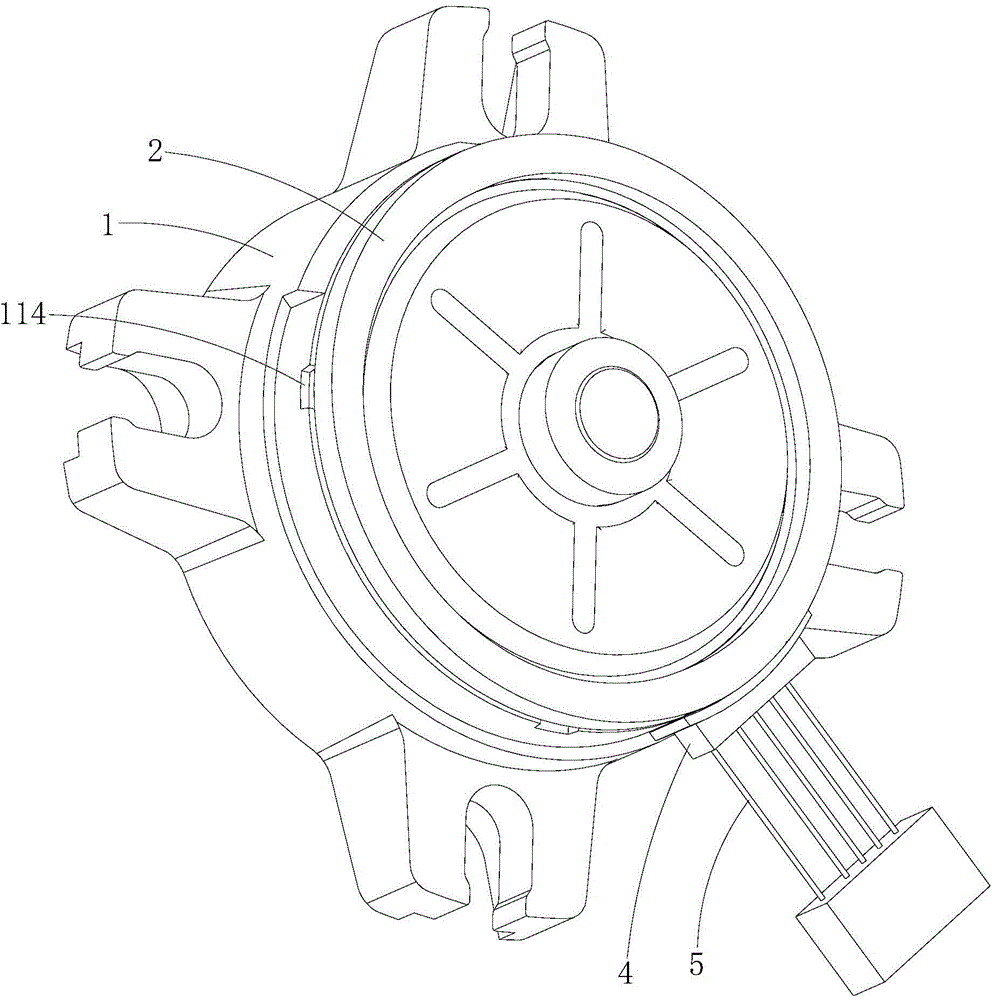

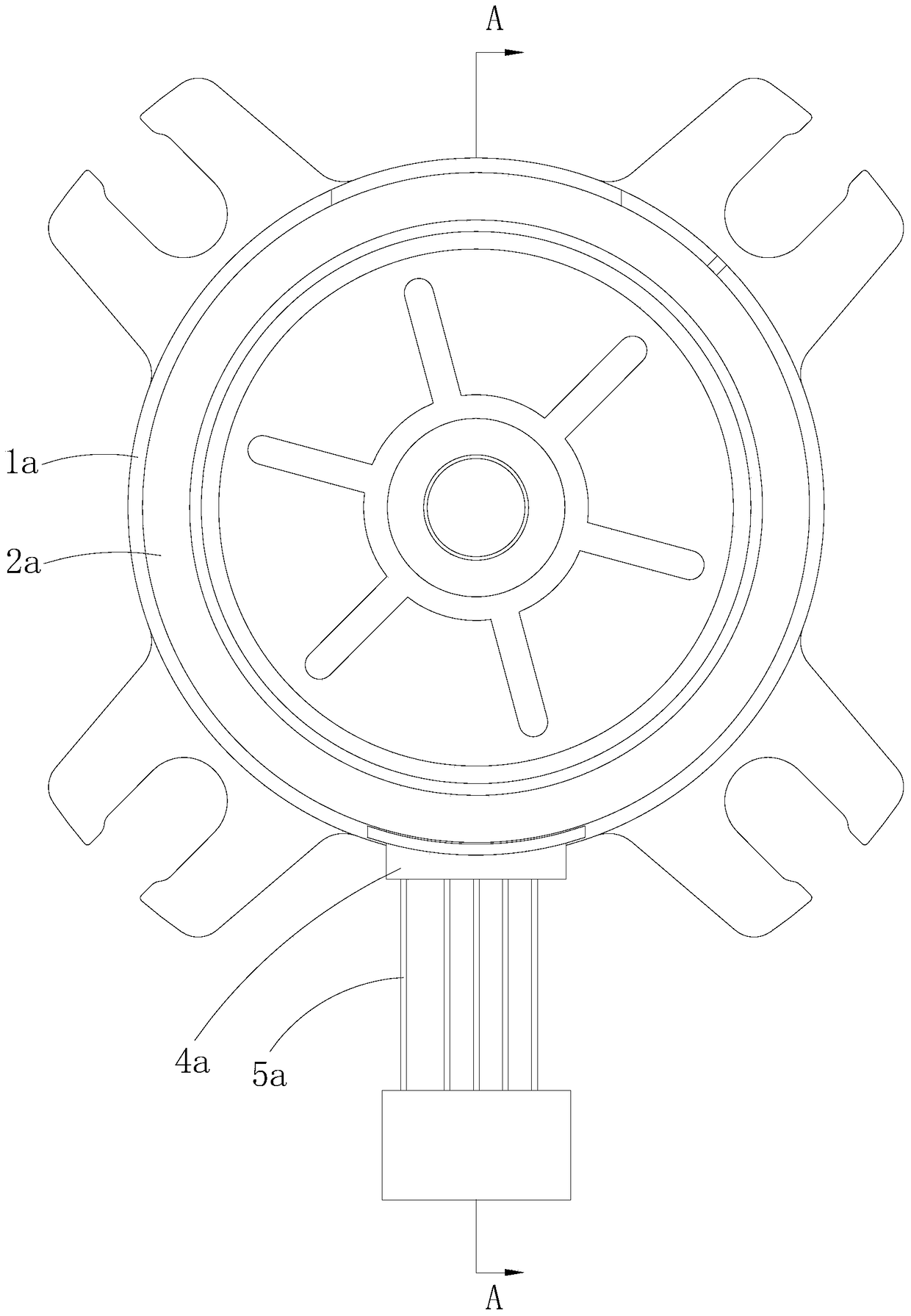

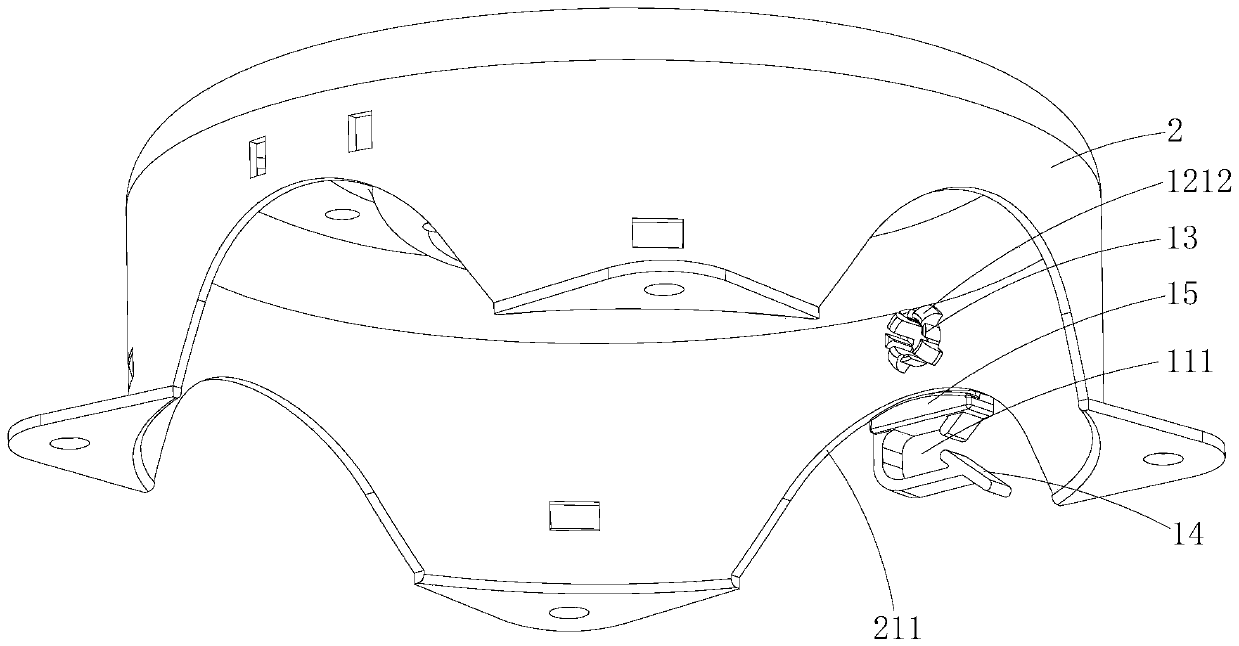

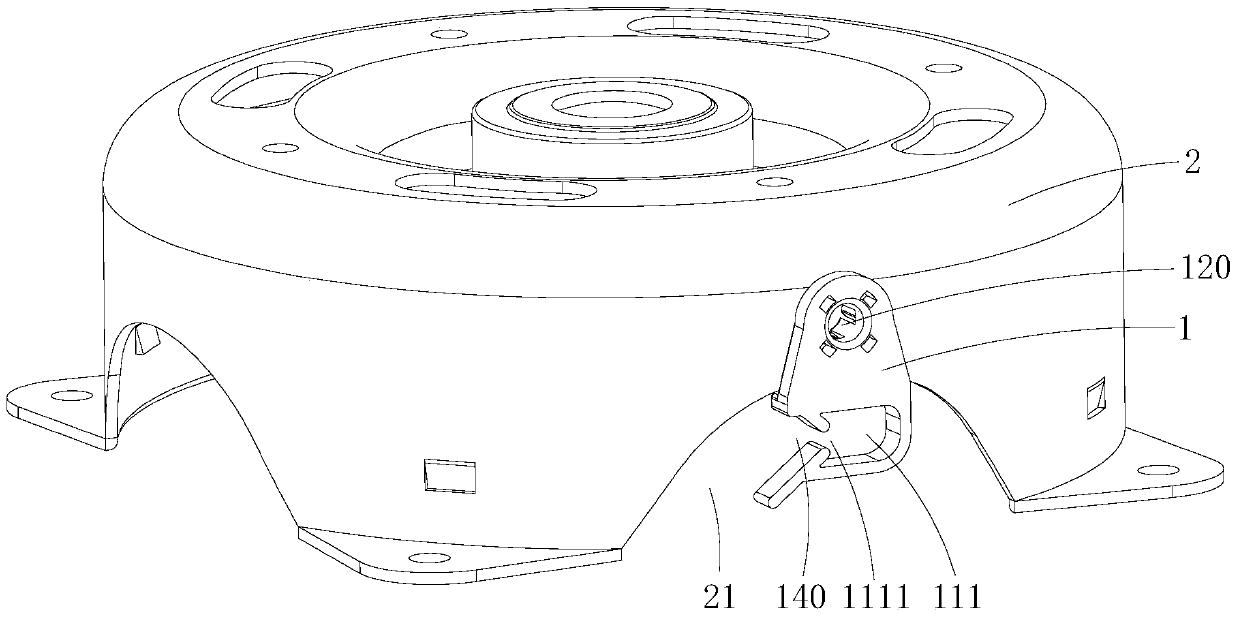

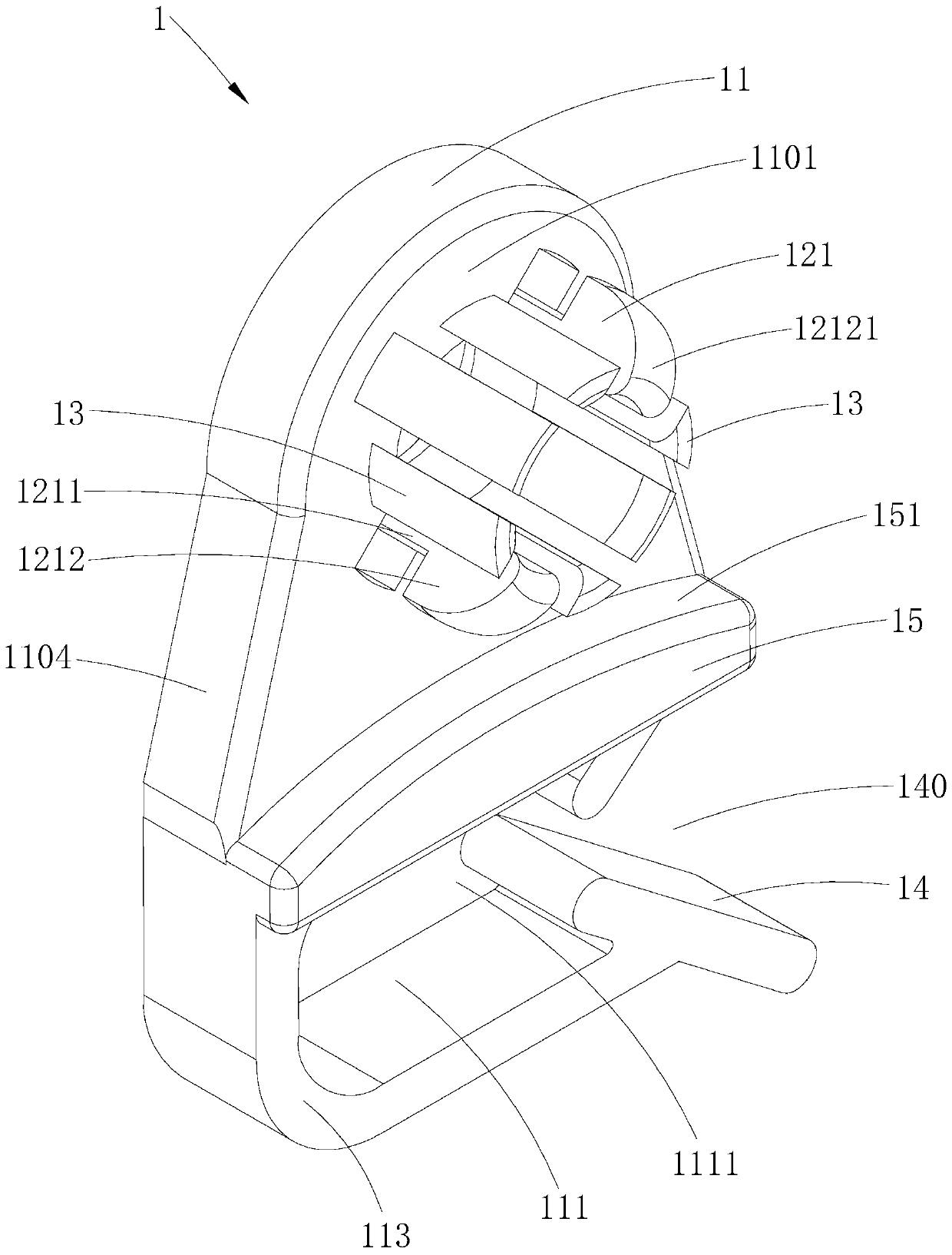

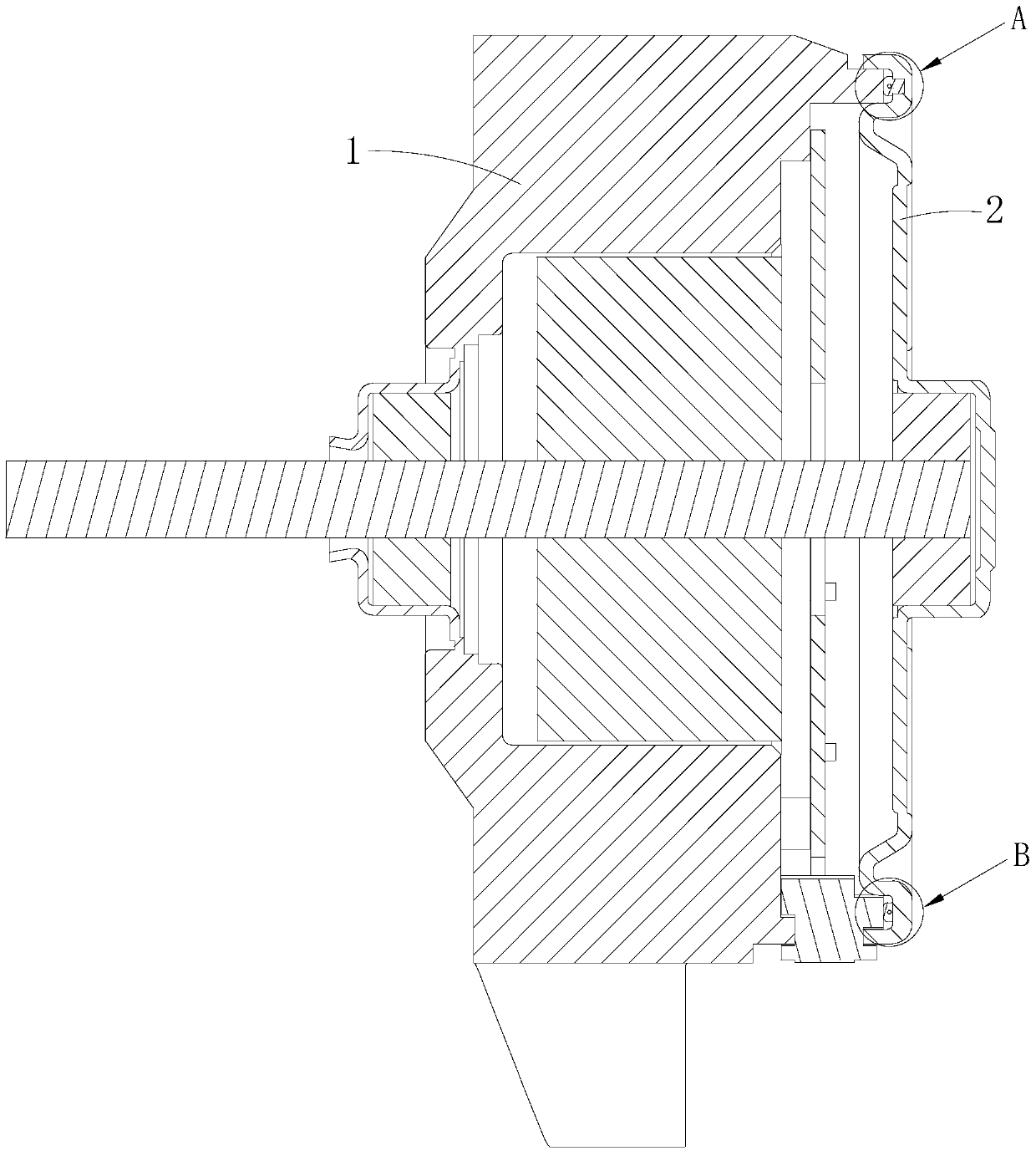

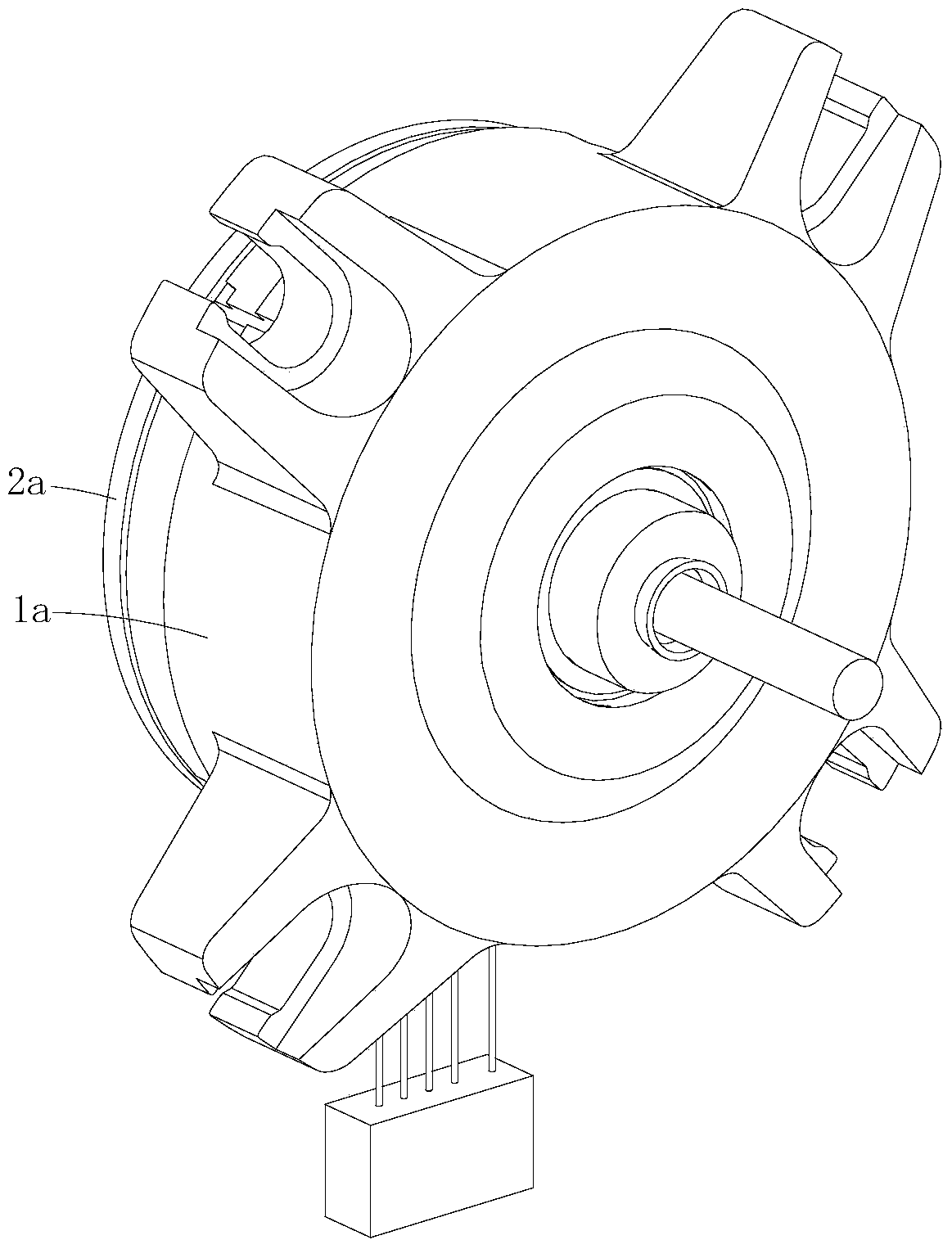

Bearing electric corrosion prevention structure of plastic package motor

ActiveCN105048692APrevent Galvanic CorrosionGuaranteed solid reliabilityStructural associationSupports/enclosures/casingsEngineeringMechanical engineering

The invention is suitable for the motor field and provides a bearing electric corrosion prevention structure of a plastic package motor. The structure comprises a first bearing bracket, a second bearing bracket arranged on the other side of a stator assembly, a plastic package shell packaged outside the stator assembly and the first bearing bracket and a metal conduction component which is conductively connected between the first bearing bracket and the second bearing bracket. The metal conduction component is an integrated structure and comprises a first conductor which is packaged in the plastic package shell and is conductively connected to the first bearing bracket, a second conductor which is arranged outside the plastic package shell and is conductively connected to the second bearing bracket and a flexible conductive body which is conductively connected between the first conductor and the second conductor and can be bent so as to adjust an included angle between the first conductor and the second conductor. The metal conduction component is conductively connected to the first bearing bracket and the second bearing bracket so that conductive reliability is high. Installation is convenient. Aging failure and shedding phenomena are not generated. Long-term reliability of bearing electric corrosion prevention performance of the plastic package motor is guaranteed.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Plastic package stator and bearing end cap waterproof sealing structure and plastic package motor

ActiveCN104539083AImproved waterproof sealGuaranteed solid reliabilitySupports/enclosures/casingsStatorInjection moulding

The invention relates to the field of motors, and discloses a plastic package stator and bearing end cap waterproof sealing structure and a plastic package motor. The plastic package stator and bearing end cap waterproof sealing structure comprises a plastic package stator and a bearing end cap at one end of the plastic package stator, wherein the plastic package stator is provided with an annular clamping flange, the bearing end cap is provided with an annular clamping groove matched with the annular clamping flange in a clamped and inserted mode, the annular clamping flange is provided with an axial end face towards the bearing end cap in the axial direction of the plastic package stator, the annular clamping groove is provided with a bottom groove face towards the plastic package stator in the axial direction of the plastic package stator, a waterproof sealing film is formed on the bottom groove face in an injection molding mode or in a coated mode, and the waterproof sealing film is elastically compressed between the axial end face and the bottom groove face The plastic package stator and bearing end cap waterproof sealing structure prevents influences of a needle insertion hole, a detection hole and a detachment notch which probably exist in the radial outer surface of the annular clamping flange on the sealing effect of a waterproof sealing ring, and achieves the aims of improving the waterproof sealing effect between the plastic package stator and the bearing end cap.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

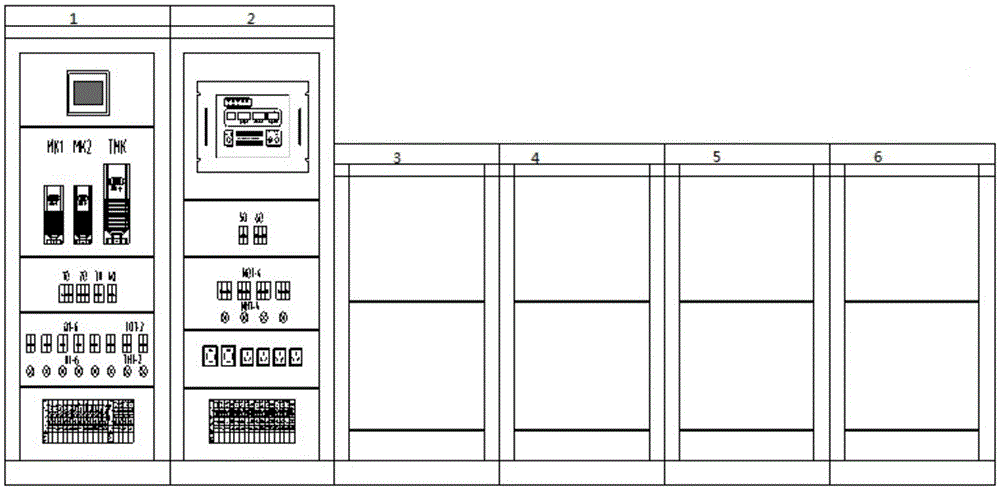

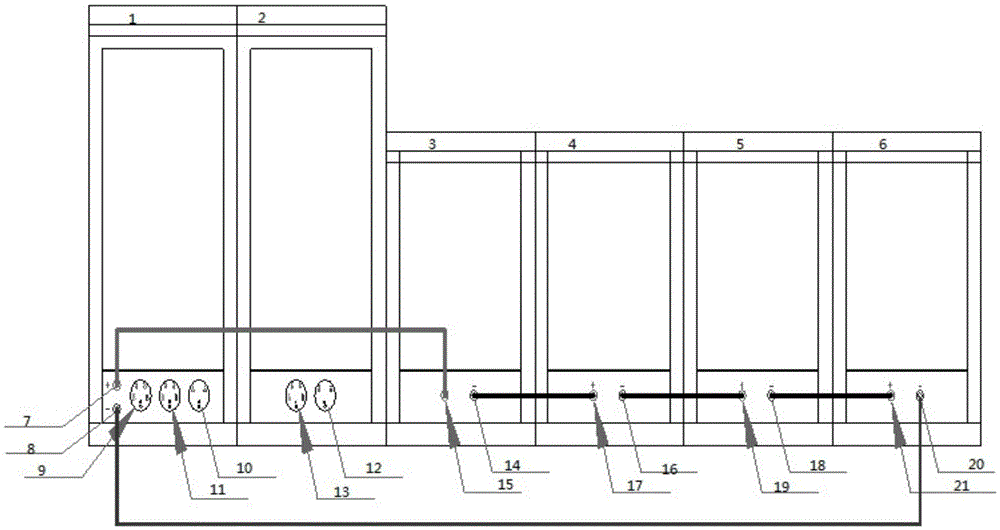

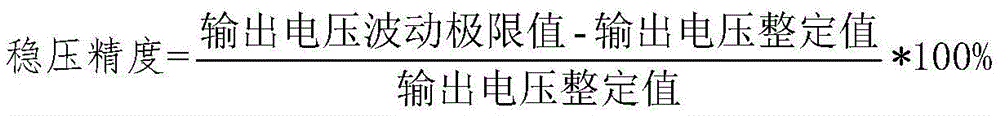

Movable modular emergency repair alternating-current and direct-current integrated power source

InactiveCN105656178AEasy module assemblyReduce volumeCharging managementSafety/protection battery circuitsModularityEngineering

The invention discloses a movable modular emergency repair alternating-current and direct-current integrated power source. The power source comprises a direct-current integrated main cabinet, storage battery cabinets and an inverter cabinet which are connected through a fast connection device. The storage battery cabinets comprise the first storage battery cabinet, the second storage battery cabinet, the third storage battery cabinet and the fourth storage battery cabinet which are distributed side by side. The direct-current integrated main cabinet comprises a high-frequency switch power source module and monitoring units. The monitoring units comprise an alternating-current monitoring unit, a direct-current monitoring unit, a switching value monitoring unit and an insulation monitoring unit. The lower portion of the direct-current integrated main cabinet is provided with an alternating-current socket and a direct-current socket which are connected to the inverter cabinet. A positive electrode input terminal of a battery pack at the bottom of the direct-current integrated main cabinet is connected with a positive electrode output terminal of a battery pack of the first storage battery cabinet. A negative electrode input terminal of the battery pack of the direct-current integrated main cabinet is connected with an output terminal of a battery pack of the fourth storage battery cabinet. The lower portion of the inverter cabinet is provided with an inverter cabinet alternating-current input socket and an inverter cabinet input socket.

Owner:XUANCHENG POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

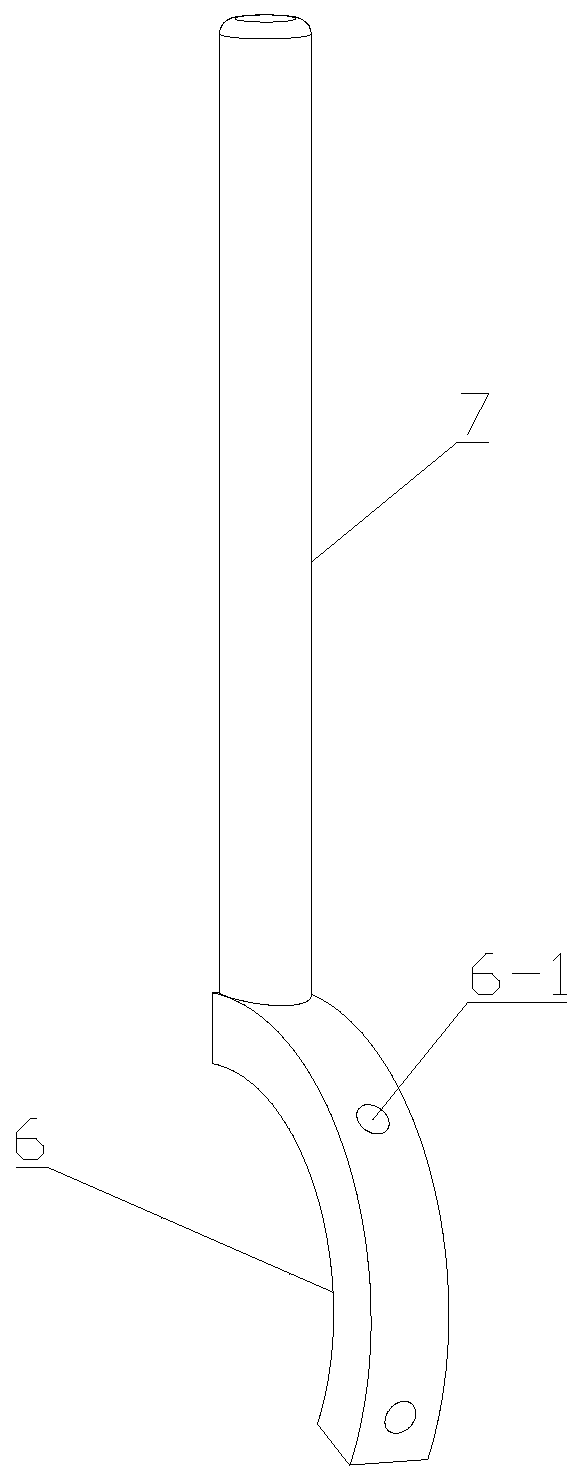

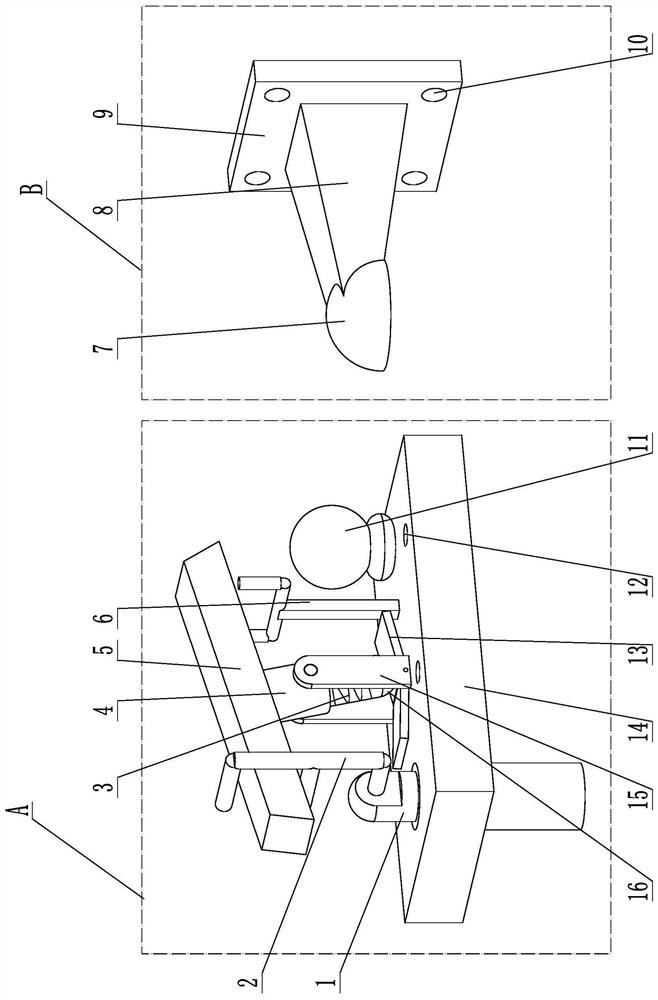

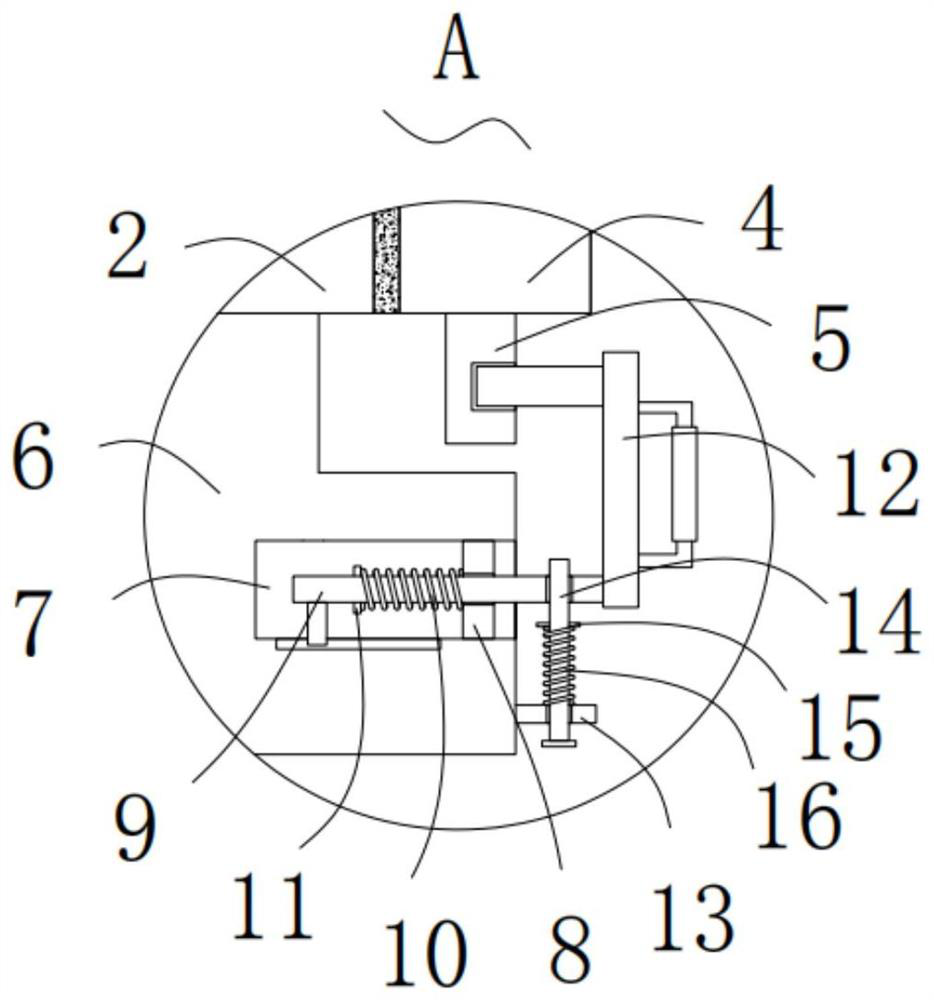

Fast tractive connection device for tractive agricultural implement

PendingCN111602480AGuaranteed solid reliabilityQuick connectionAgricultural machinesHydraulic cylinderAgricultural engineering

The invention provides a fast tractive connection device for a tractive agricultural implement and belongs to agricultural machinery. The device comprises an active pulling seat body and a follow-up pulling rod body, wherein the active pulling seat body is formed by assembling a traction power machine connection plate, a two-way hydraulic cylinder, a trough-shaped push-pull frame, a locking groove, a barrel-shaped housing body, a pressure spring shell, a pressure spring, a support frame, an arc-shaped wrap board, a limiting frame and a spherical connector; the follow-up pulling rod body is formed by assembling a traction implement connection plate, a pulling arm and a hemispherical connection cover; and the hemispherical connection cover can cover the spherical connector in a universal rotation manner to hinge the active pulling seat body and the follow-up pulling rod body into a whole. The fast tractive connection device achieves fast connection of the tractive agricultural implementand a traction power machine and has the characteristics of being novel, unique and reasonable in structure, high in connection operation efficiency, labor-saving, effort-saving, good in usability andreliable in use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

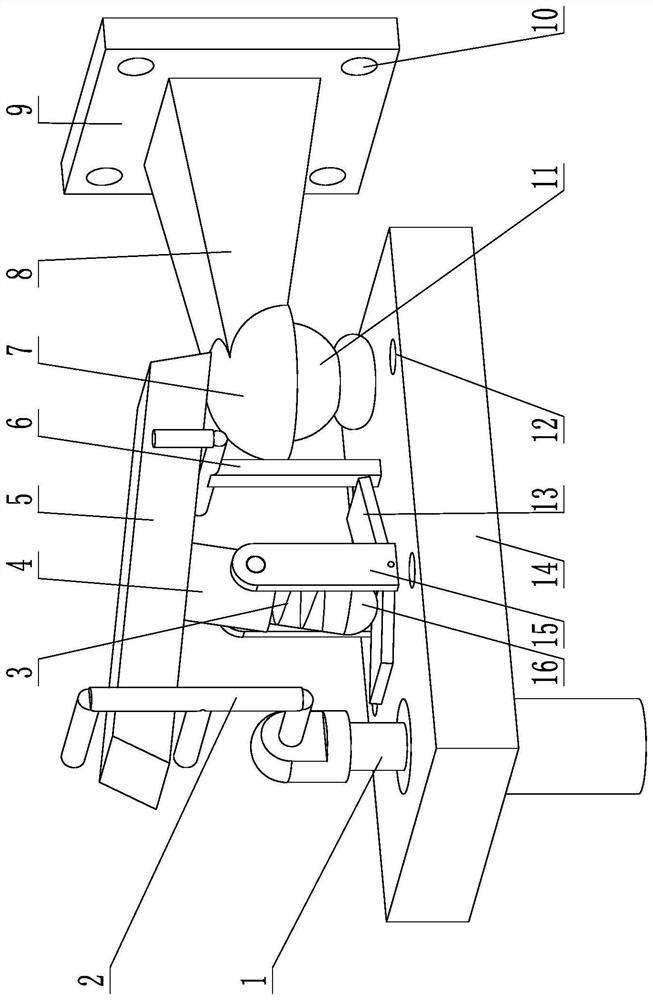

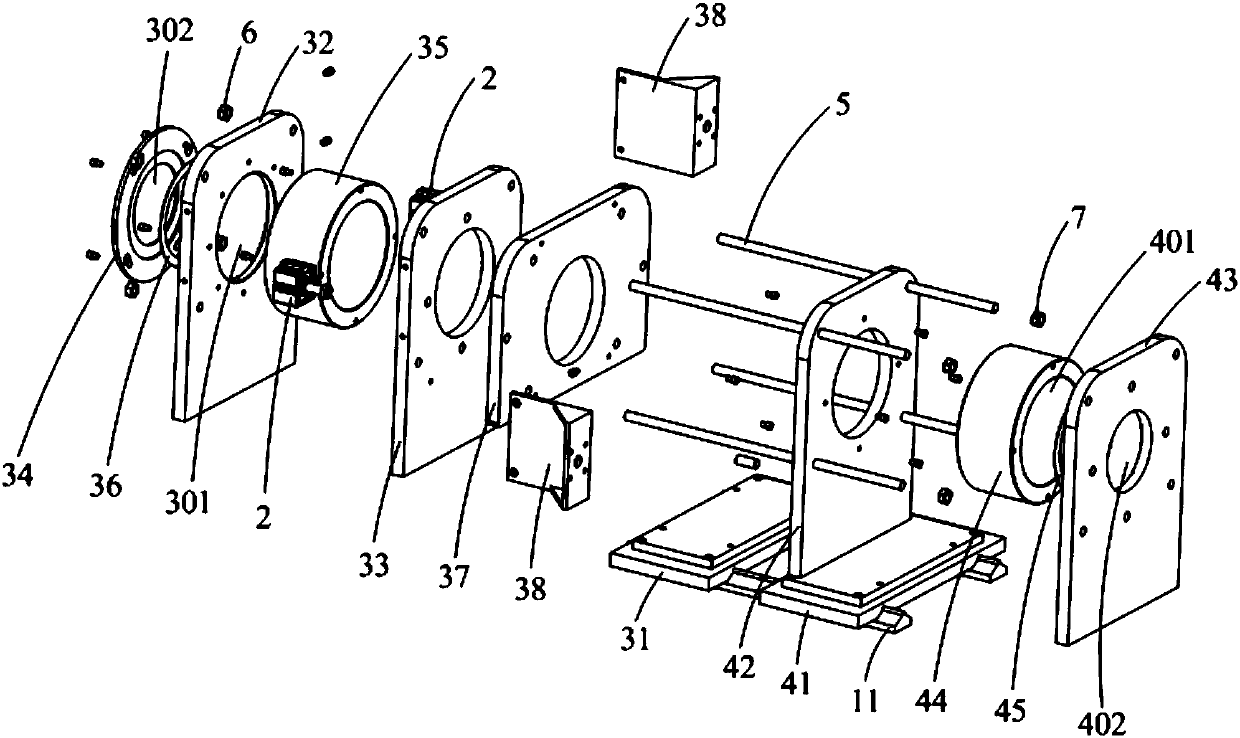

Honing tool for inner wall of sleeve component

PendingCN107717712AGuaranteed solid reliabilityGuaranteed uniformityHoning machinesInner wall zoneEngineering

The invention is applicable to the field of honing machining equipment, and discloses a honing tool for the inner wall of a sleeve component. The honing tool comprises a fixed seat, pressurizing assemblies, a first jacket assembly into which one axial end of the sleeve component penetrates and is located, and a second jacket assembly into which the other axial end of the sleeve component penetrates and is located, wherein limiting structures for preventing axial movement and displacement of the two ends of the sleeve component are respectively arranged on the first jacket assembly and the second jacket assembly; the first jacket assembly and the second jacket assembly are mounted on the fixed seat in a spacing manner; the first jacket assembly is connected with the fixed seat in a slidingmanner; and the pressurizing assemblies can provide tensioning force for the first jacket assembly towards the second jacket assembly. The sleeve component is mounted through the honing tool for the inner wall of the sleeve component, so that the sleeve component is high in mounting stability and reliability, and the production quality and the production efficiency of the sleeve component are guaranteed; and furthermore, the honing tool for the inner wall of the sleeve component can be used for mounting various sleeve components in different length sizes, so that the honing tool is high in universality.

Owner:深圳市华盛源机电有限公司

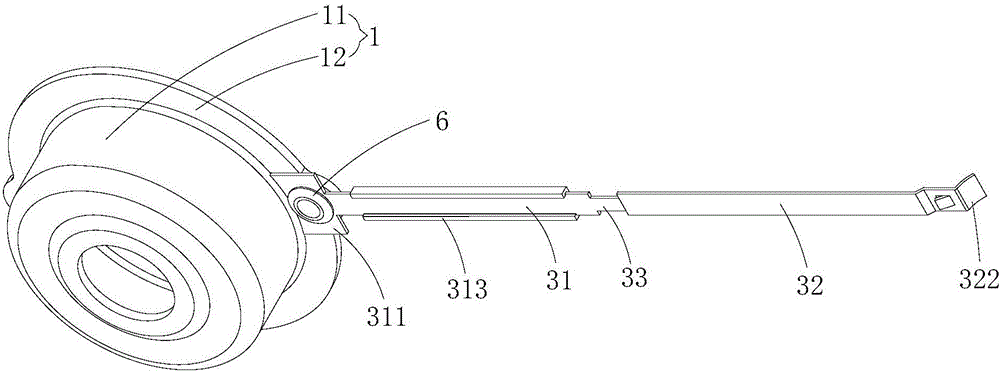

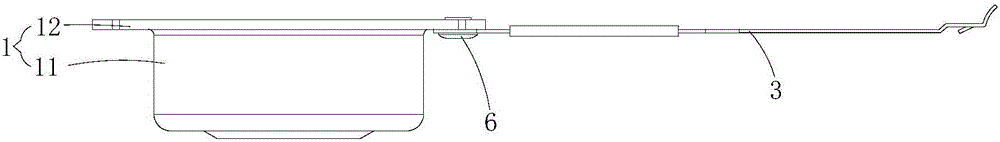

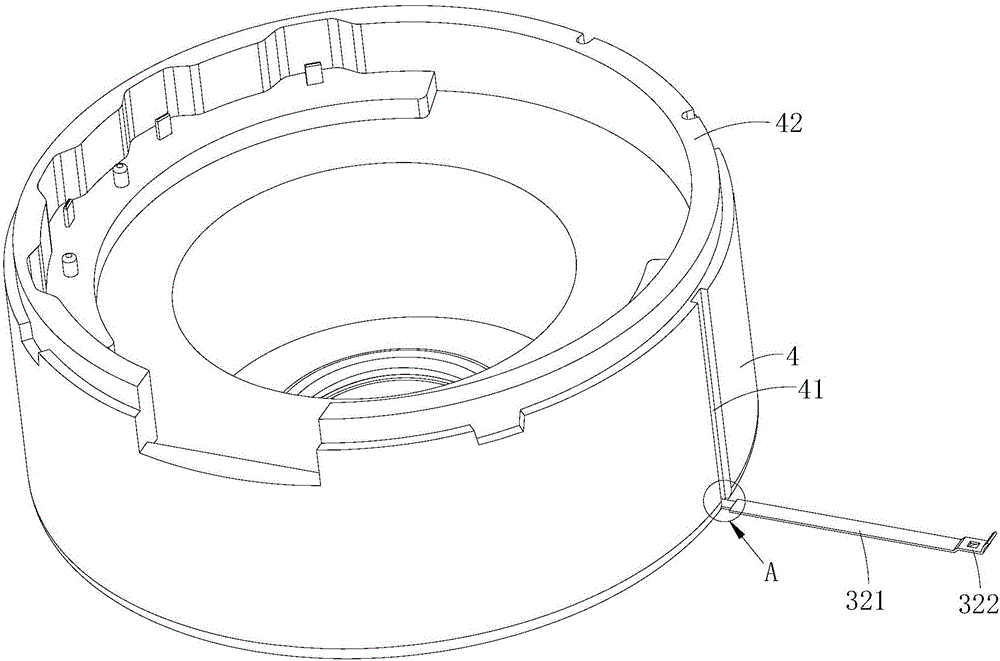

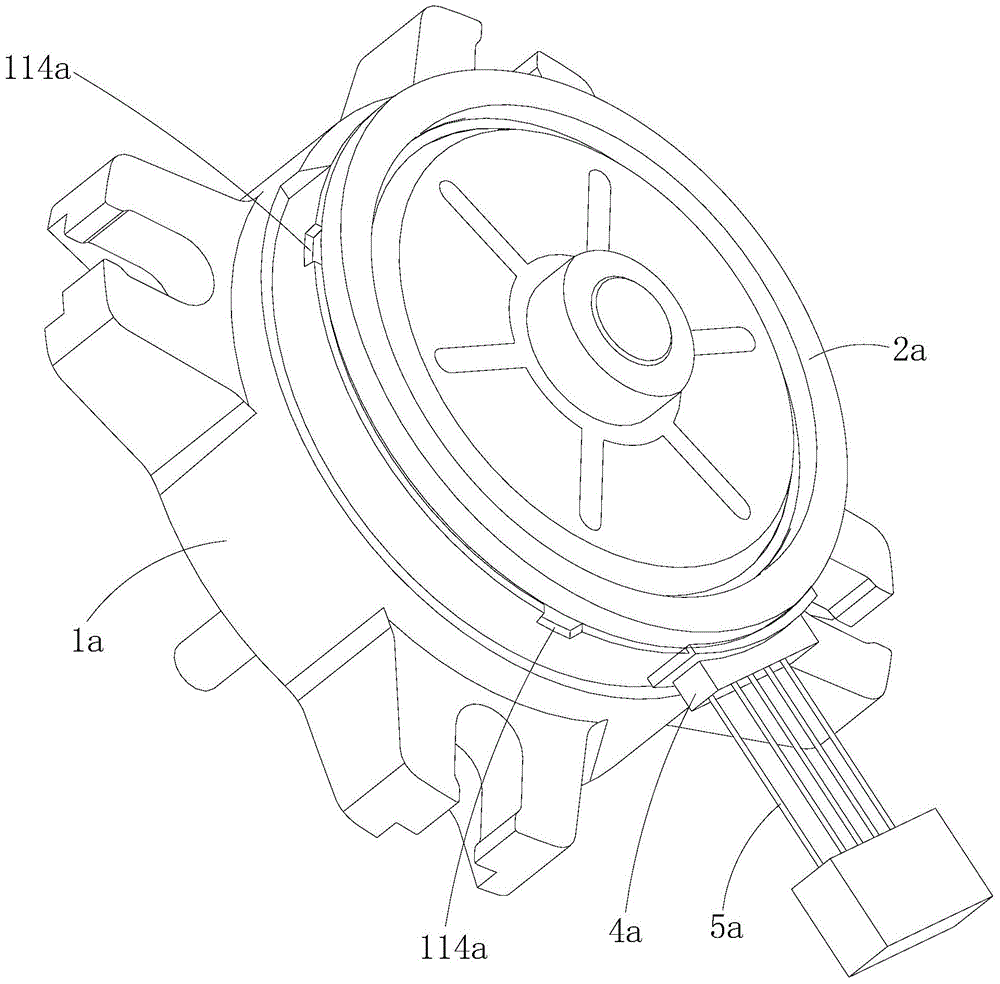

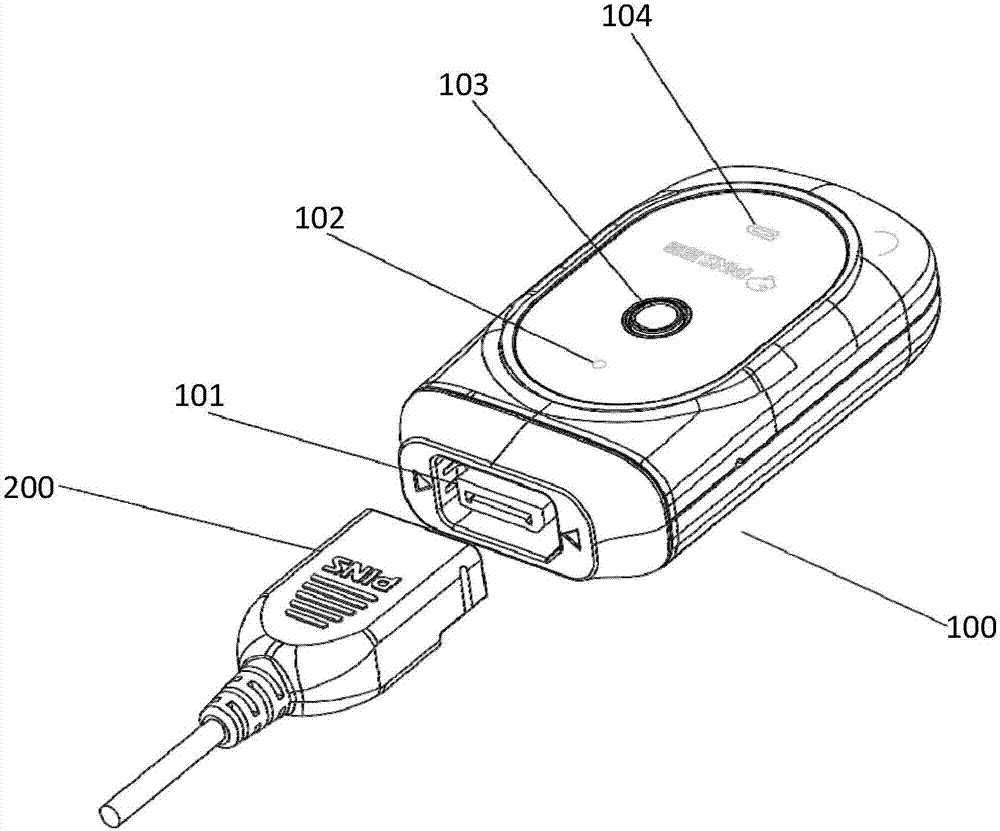

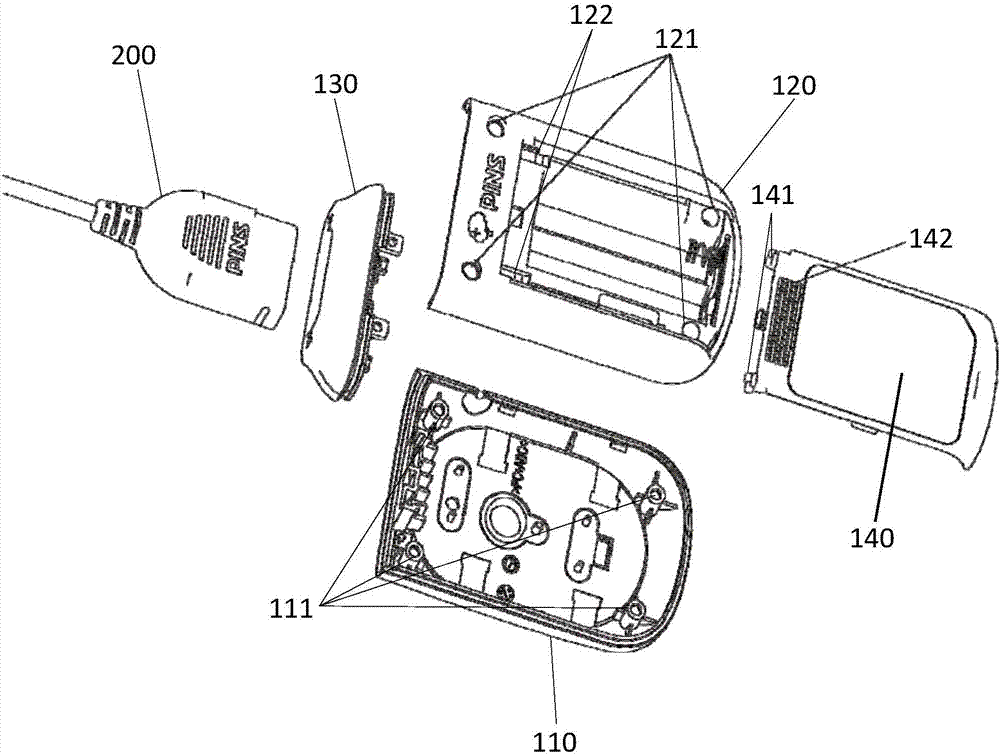

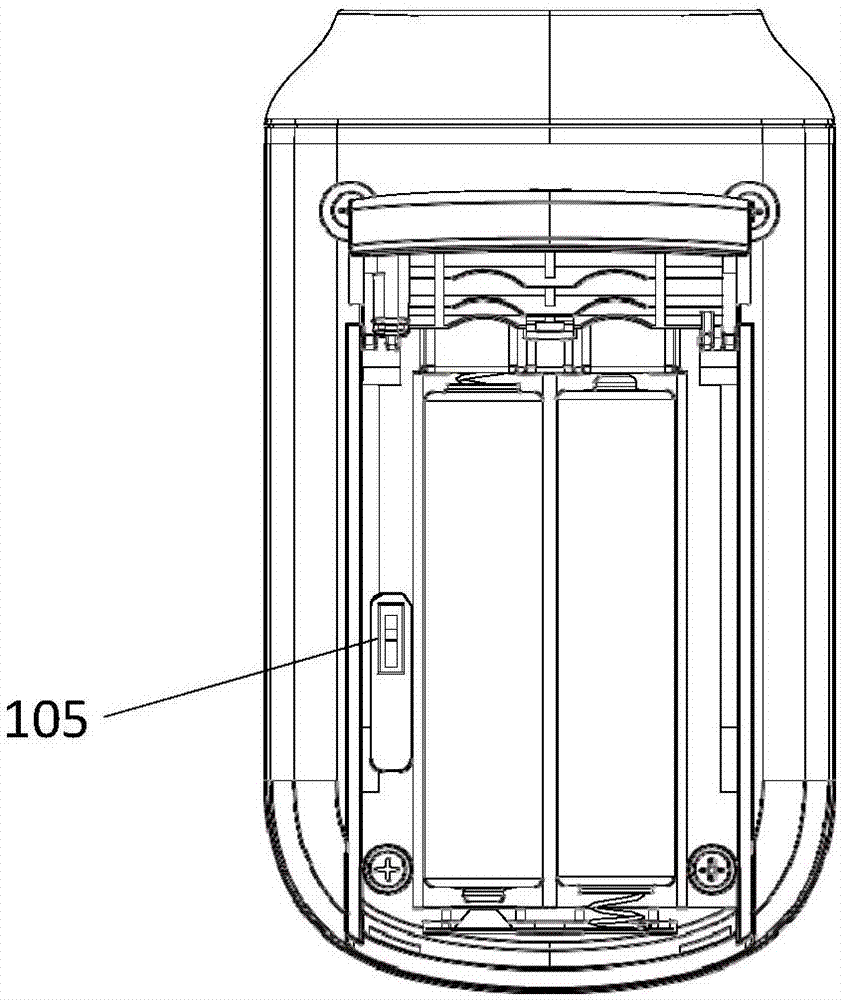

External pulse generator of neural regulation and control body

InactiveCN107952171AImprove interchangeabilityNot easy to strain and agingImplantable neurostimulatorsArtificial respirationNeural regulationBoard-to-board connector

The invention belongs to the technical field of medical instruments, and particularly relates to an external pulse generator of a neural regulation and control body. The external pulse generator comprises a front shell, a rear shell, an end cover, a battery cover, a wire interface end plug and a PCB. The front shell, the rear shell and the end cover are used for supporting the PCB in the shell. The PCB comprises a first PCB and a second PCB. The first PCB and the second PCB are connected through a board-to-board connector. The first PCB is fixed in the front shell, and the second PCB is fixedin the rear shell. The first PCB and the second PCB are connected with the board-to-board connector through an FPC. The wire interface end plug is installed on the second PCB. According to the invention, a display port interface can be used at the connecting end of a wire based on an optimized installation structure, so that the advantages of high interchangeability and low cost are realized. A metal frame is not prone to strain and aging. In addition, the bandwidth provided by the display port can be up to 10. 8Gb / s. The upgrading of future products is facilitated.

Owner:BEIJING PINS MEDICAL

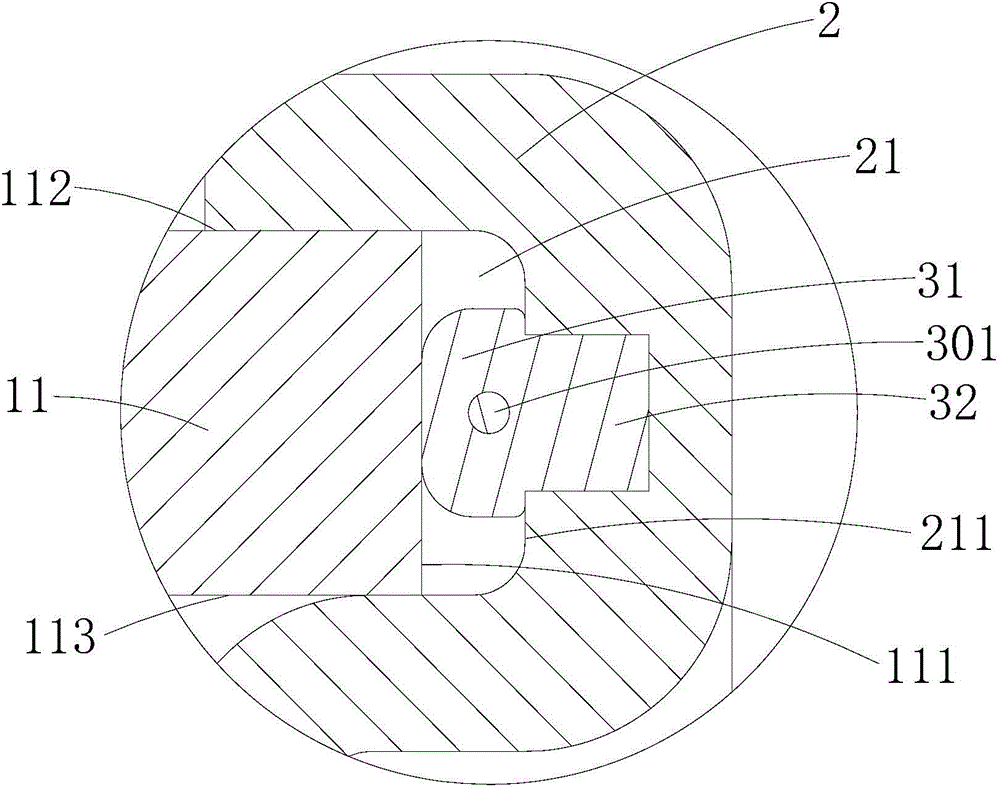

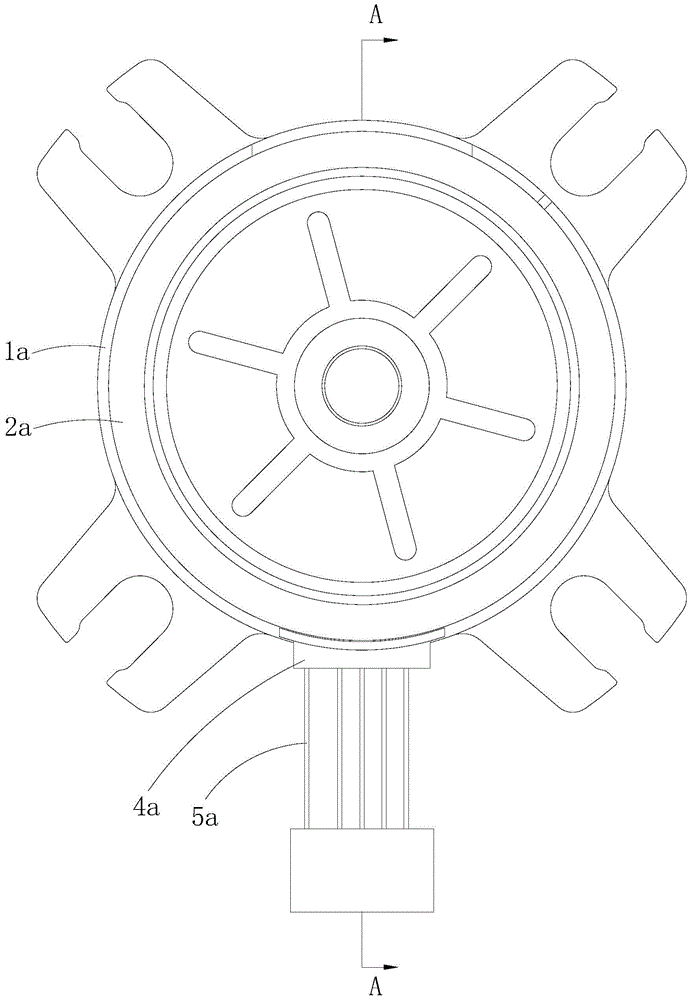

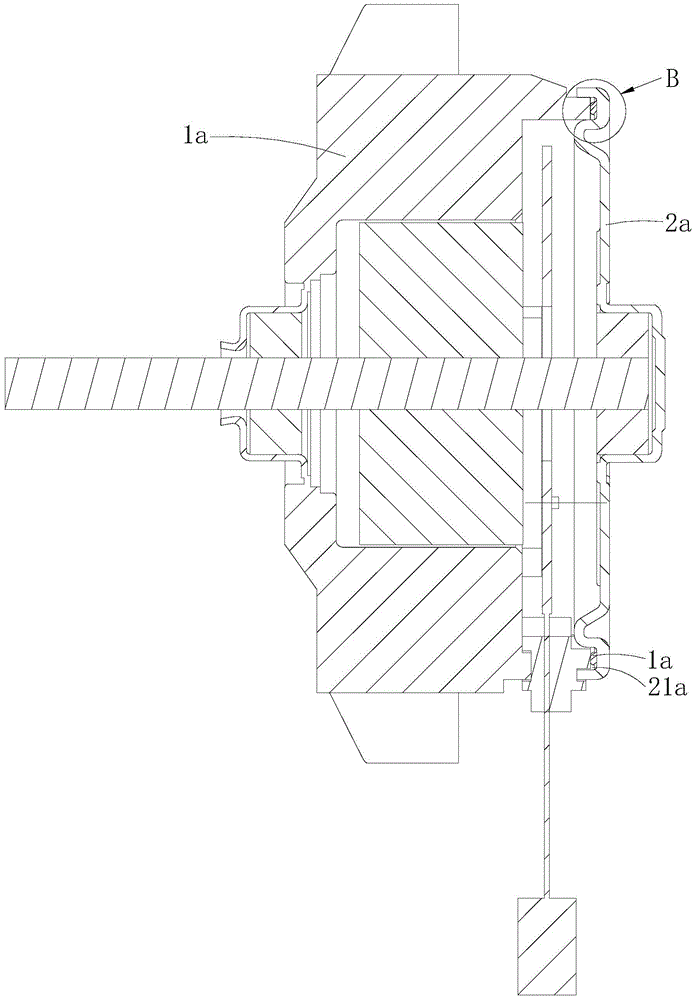

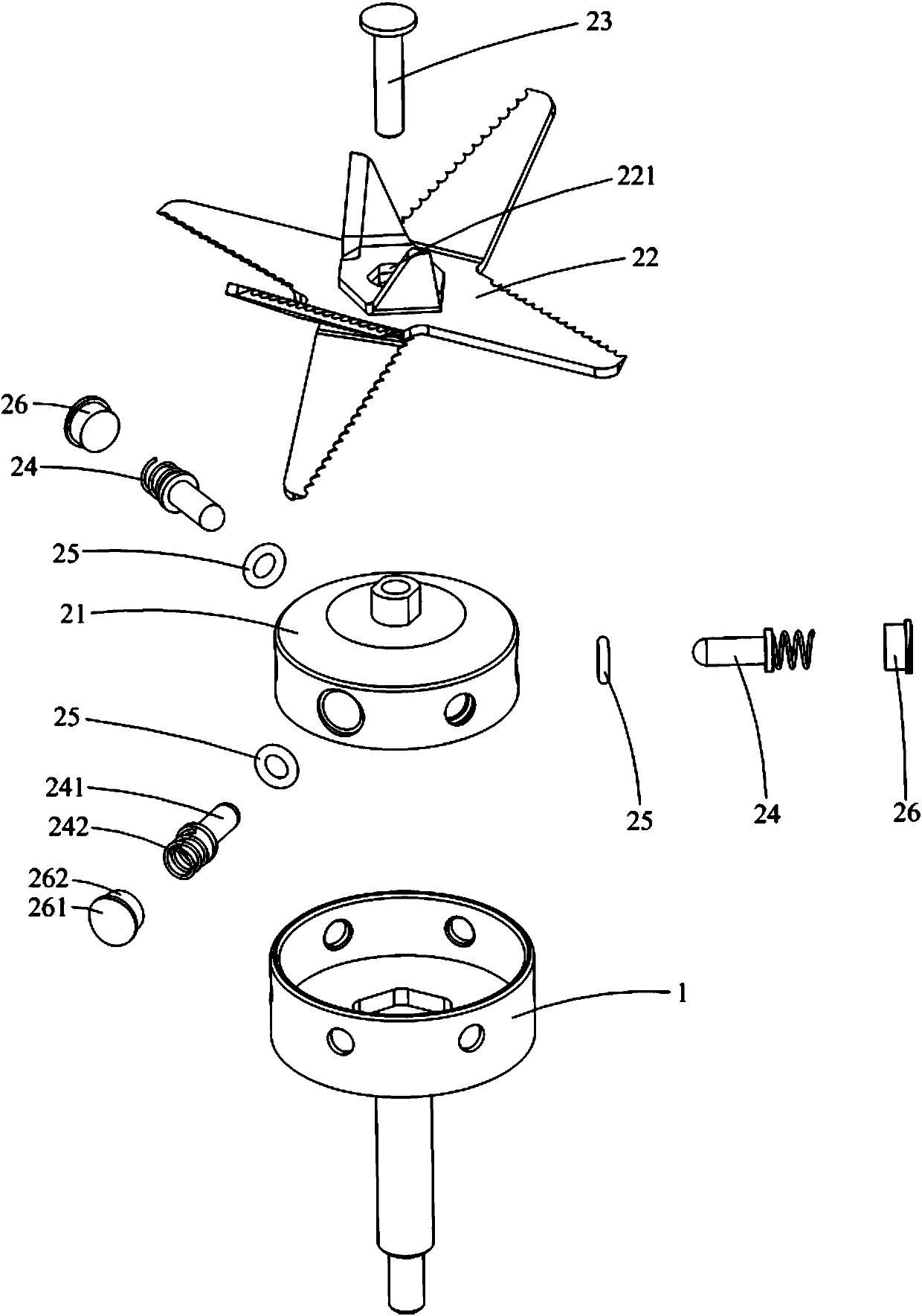

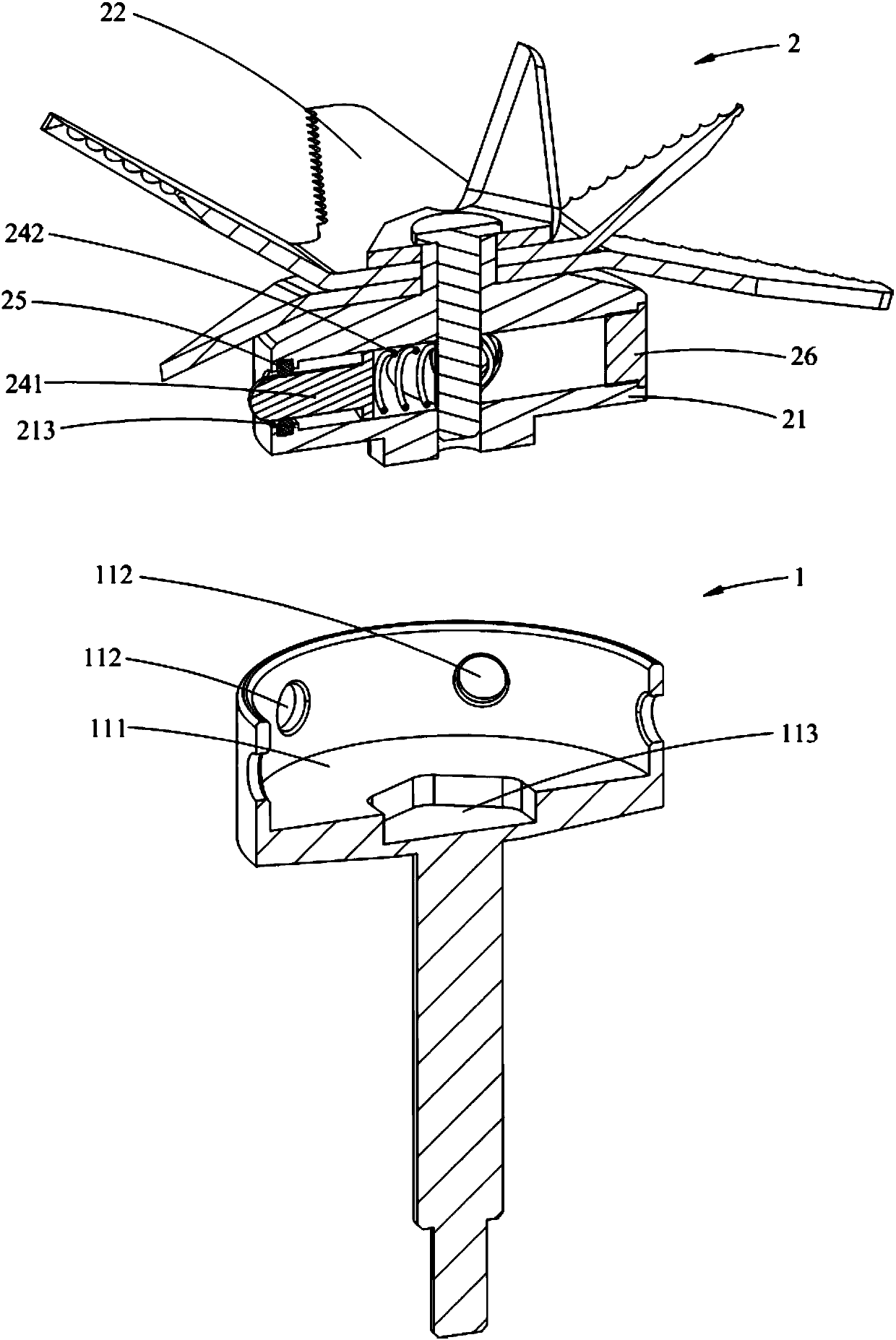

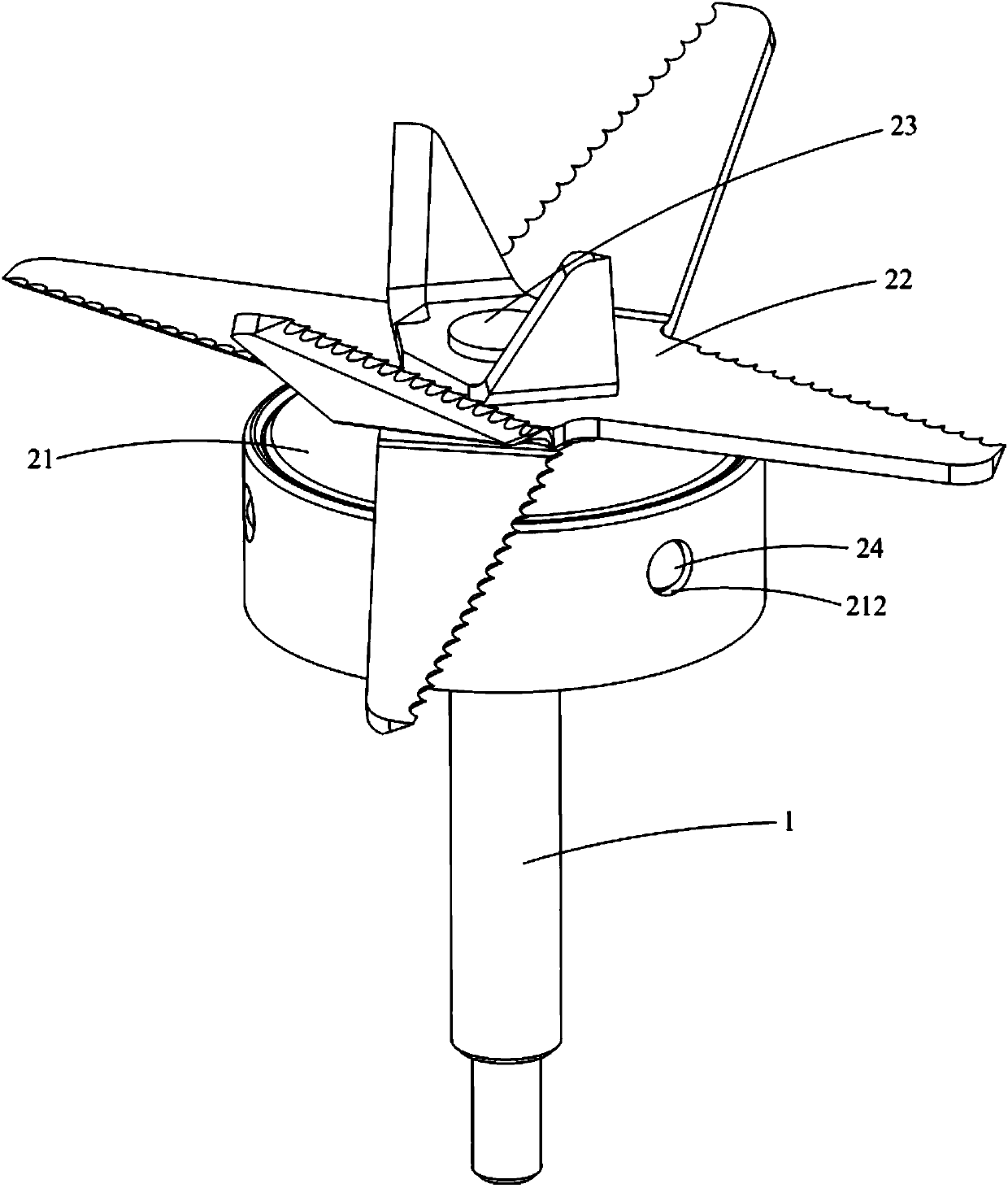

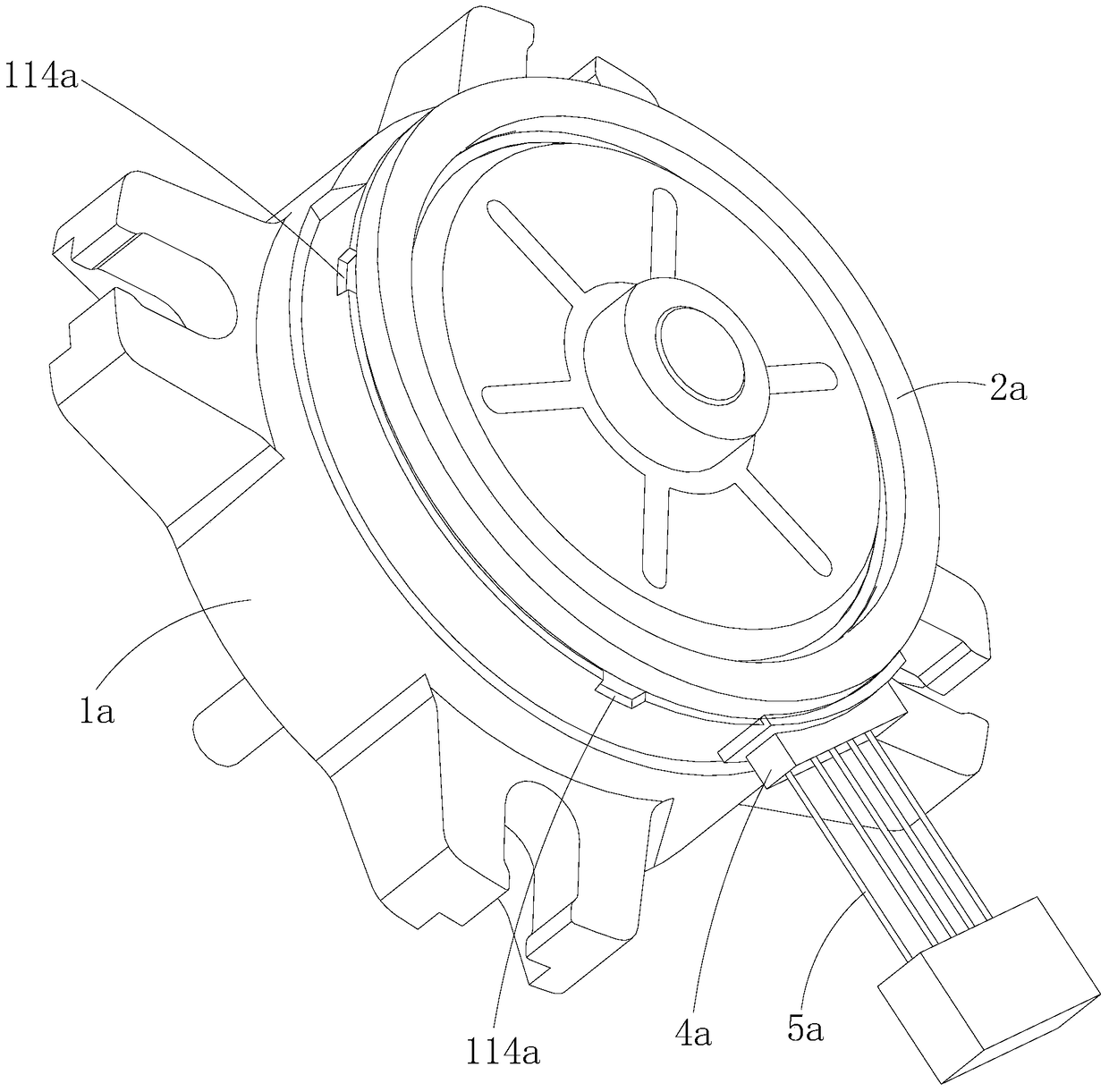

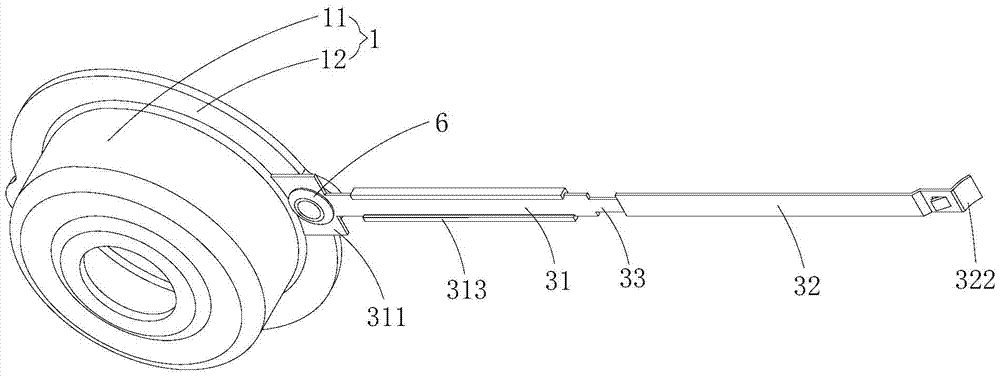

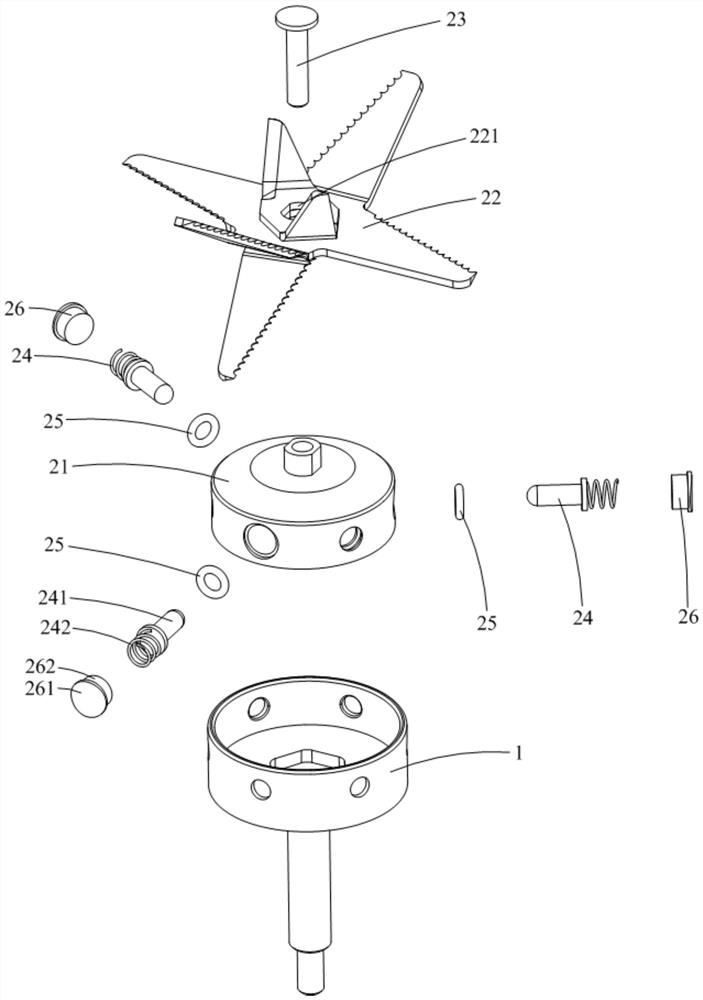

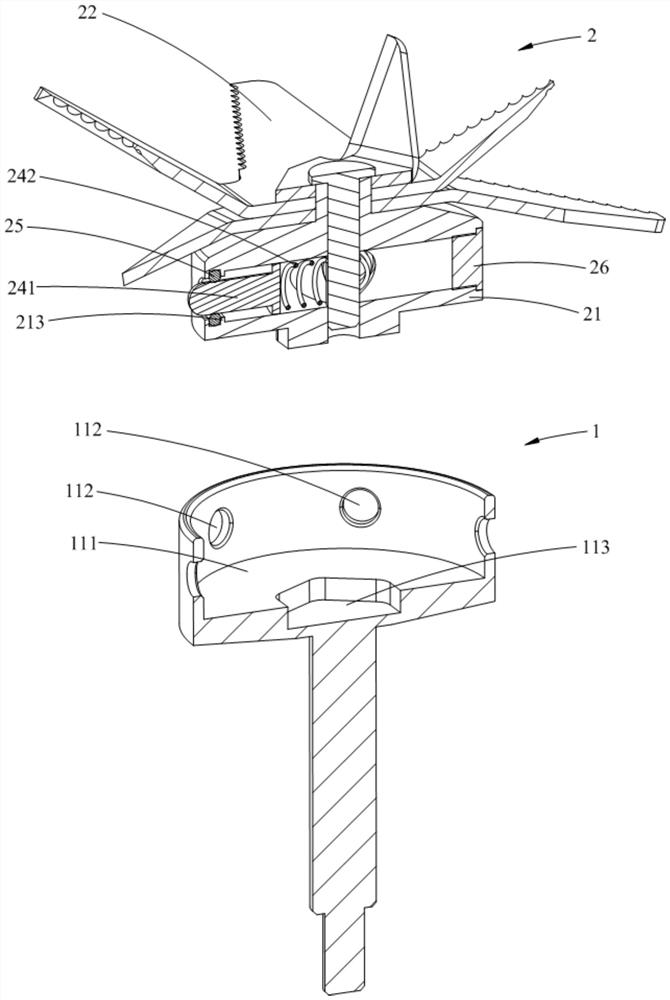

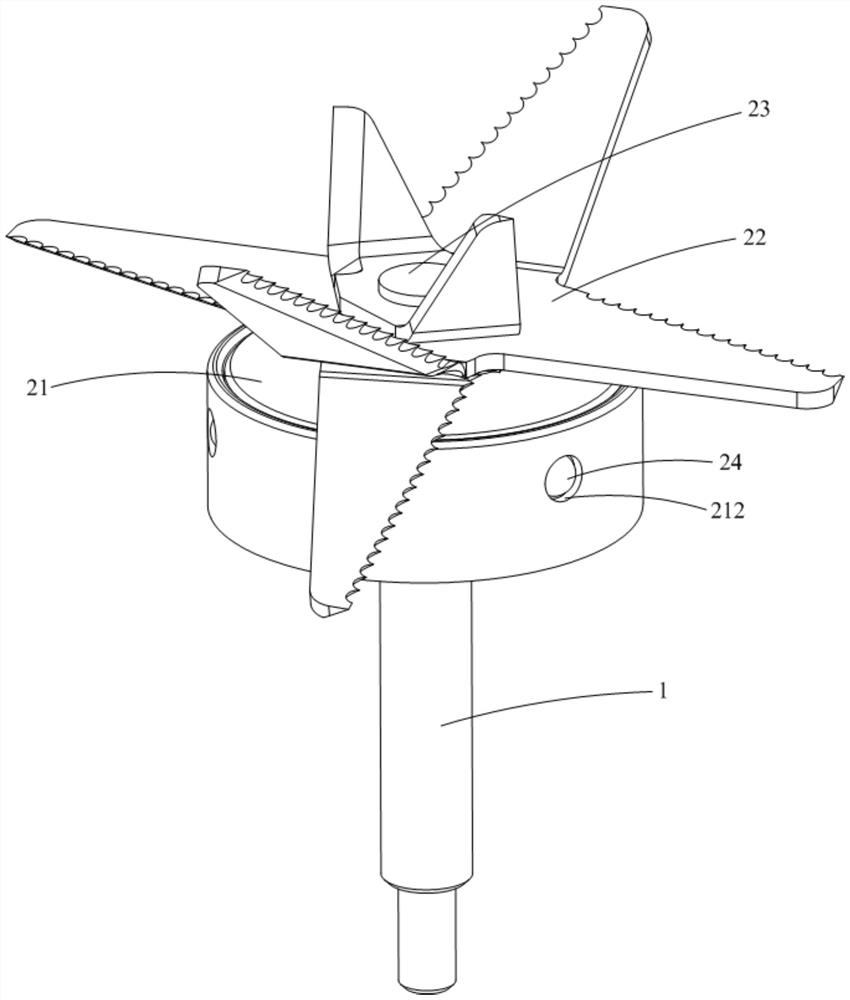

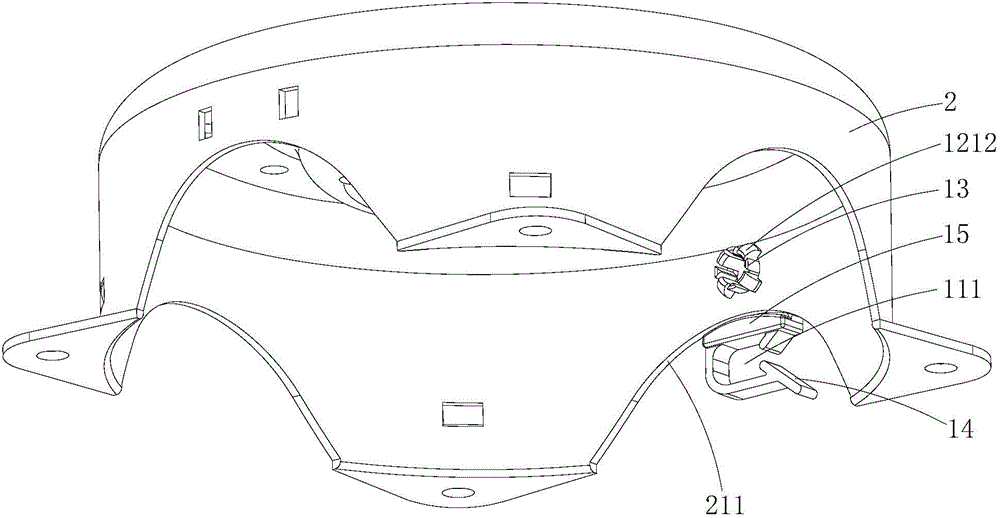

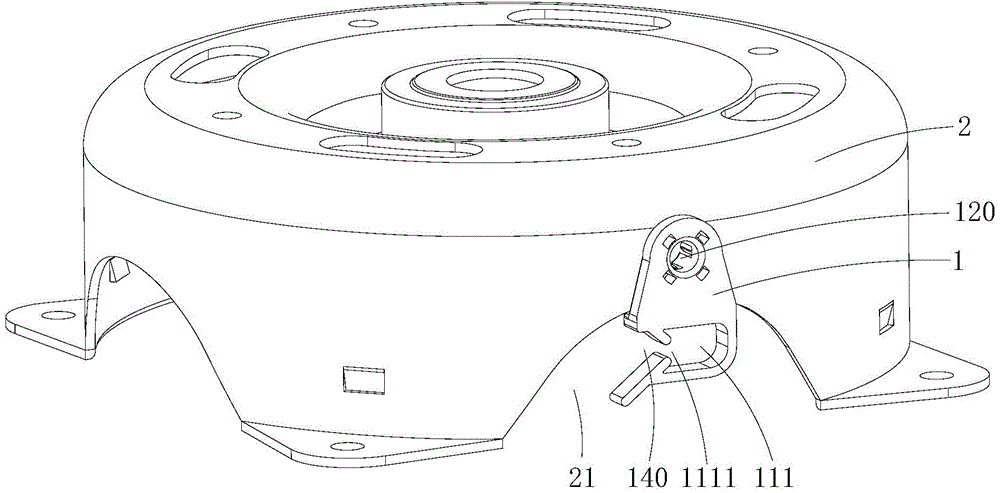

Cutter assembly and food processor

ActiveCN109700340ARealize lateral limitRealize the vertical limitKitchen equipmentElastic componentEngineering

The invention is applicable to the field of household electric appliances, and discloses a cutter assembly and a food processor. The cutter assembly comprises a cutter shaft and a cutter detachably mounted on the cutter shaft, wherein a concave cavity is arranged in the top of the cutter shaft, and positioning holes are arranged in the side wall of the concave cavity; the cutter comprises a base,a blade, a locking positioning component and elastic components, the base is accommodated and positioned in the concave cavity, the locking positioning component is connected with the blade and the base in a penetrating manner along the vertical direction, each elastic component comprises a positioning rod with one end arranged in the base and the other end horizontally extending out of the base and inserted in the corresponding positioning hole, and a first elastic part with two ends butted to the positioning rod and the locking positioning component, and the end face, far away from each first elastic part, of the corresponding positioning rod is an inclined face or an arc face. When the cutter assembly rotates, under the effect of the centrifugal force, the positioning rods further extend out from the base and are inserted into the positioning holes, so that the phenomenon that the base slides from the concave cavity and flies out is avoided, thus the stable reliability when the cutter is mounted on the cutter shaft is guaranteed, and in addition, the mounting and dismounting of the cutter and the cutter shaft are convenient.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

Waterproof sealing structure of plastic-encapsulated stator and bearing end cover and plastic-encapsulated motor

ActiveCN104539083BGood waterproof and sealing performanceGuaranteed solid reliabilitySupports/enclosures/casingsInjection mouldingNeedle insertion

The invention relates to the field of motors, and discloses a plastic package stator and bearing end cap waterproof sealing structure and a plastic package motor. The plastic package stator and bearing end cap waterproof sealing structure comprises a plastic package stator and a bearing end cap at one end of the plastic package stator, wherein the plastic package stator is provided with an annular clamping flange, the bearing end cap is provided with an annular clamping groove matched with the annular clamping flange in a clamped and inserted mode, the annular clamping flange is provided with an axial end face towards the bearing end cap in the axial direction of the plastic package stator, the annular clamping groove is provided with a bottom groove face towards the plastic package stator in the axial direction of the plastic package stator, a waterproof sealing film is formed on the bottom groove face in an injection molding mode or in a coated mode, and the waterproof sealing film is elastically compressed between the axial end face and the bottom groove face The plastic package stator and bearing end cap waterproof sealing structure prevents influences of a needle insertion hole, a detection hole and a detachment notch which probably exist in the radial outer surface of the annular clamping flange on the sealing effect of a waterproof sealing ring, and achieves the aims of improving the waterproof sealing effect between the plastic package stator and the bearing end cap.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Anti-corrosion bearing structure of plastic-encapsulated motor

ActiveCN105048692BPrevent Galvanic CorrosionGuaranteed solid reliabilityAssociation with grounding devicesSupports/enclosures/casingsOff phenomenonElectrical and Electronics engineering

The present invention is applicable to the field of motors, and provides a bearing electric corrosion prevention structure for plastic-encapsulated motors, which includes a first bearing bracket, a second bearing bracket arranged on the other side of the stator assembly, and a bearing bracket packaged between the stator assembly and the first bearing bracket. The outer plastic casing and the metal conductive member electrically connected between the first bearing bracket and the second bearing bracket. The first electrical conductor, the second electrical conductor arranged outside the plastic-encapsulated shell and electrically connected to the second bearing bracket, and the second electrical conductor electrically connected between the first electrical conductor and the second electrical conductor and can be bent to adjust the first electrical conductor and the second electrical conductor Bendable conductors with angles between second conductors. It electrically connects the first bearing bracket and the second bearing bracket through a metal conductive member, which has high conductivity reliability, is easy to install, and will not appear aging failure and falling off, which ensures the long-term performance of plastic-sealed motors against electric corrosion of bearings reliability.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

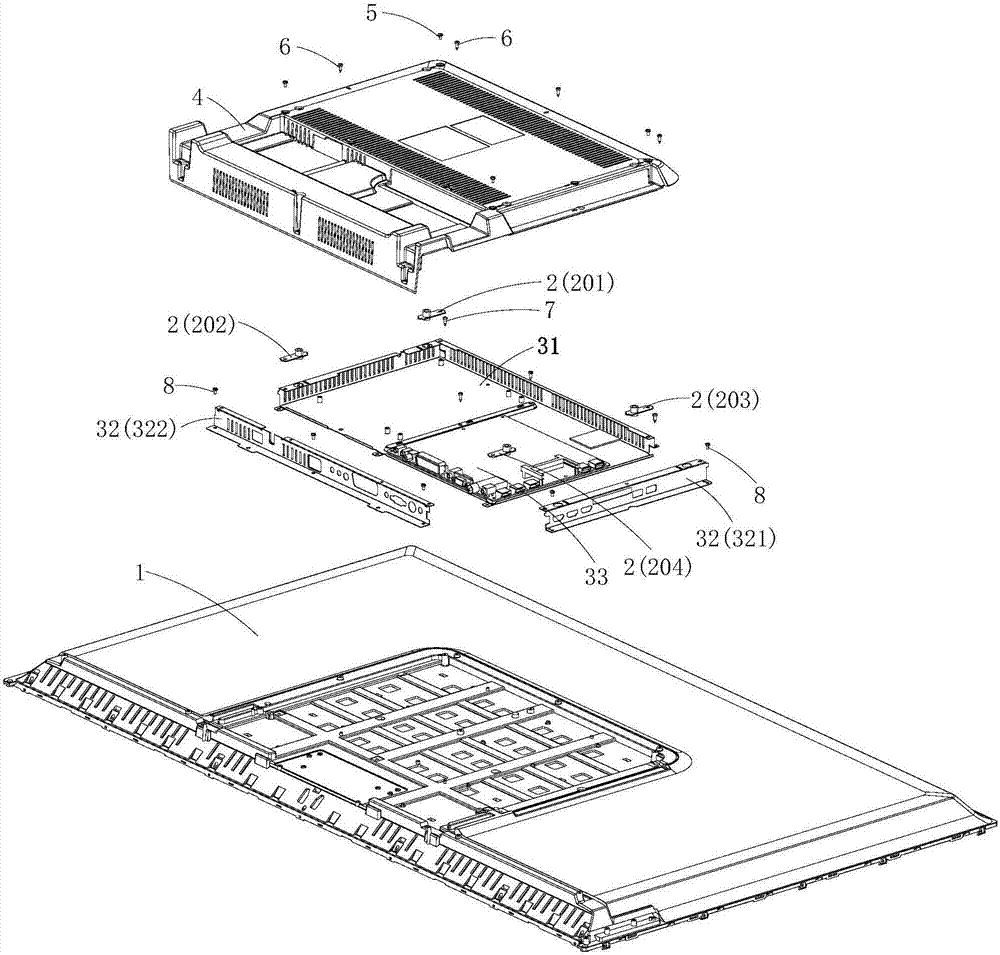

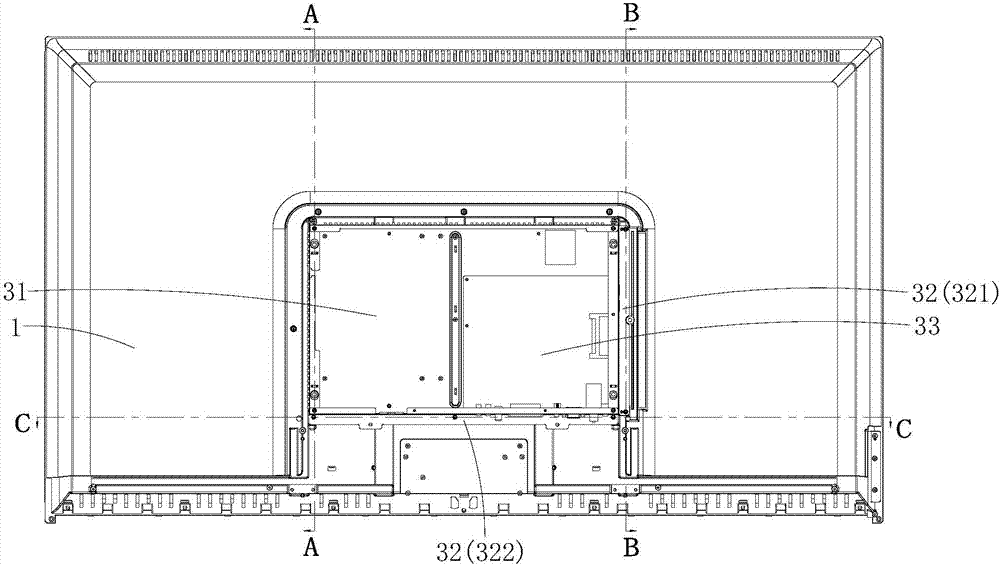

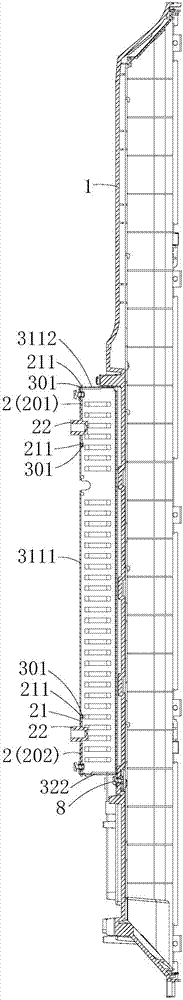

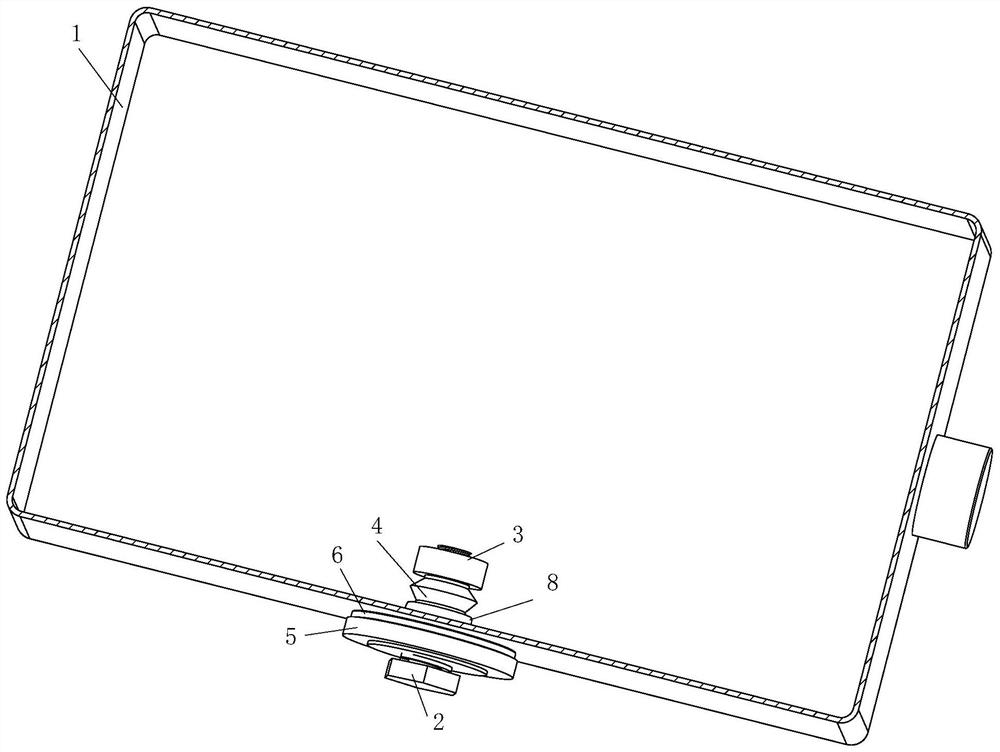

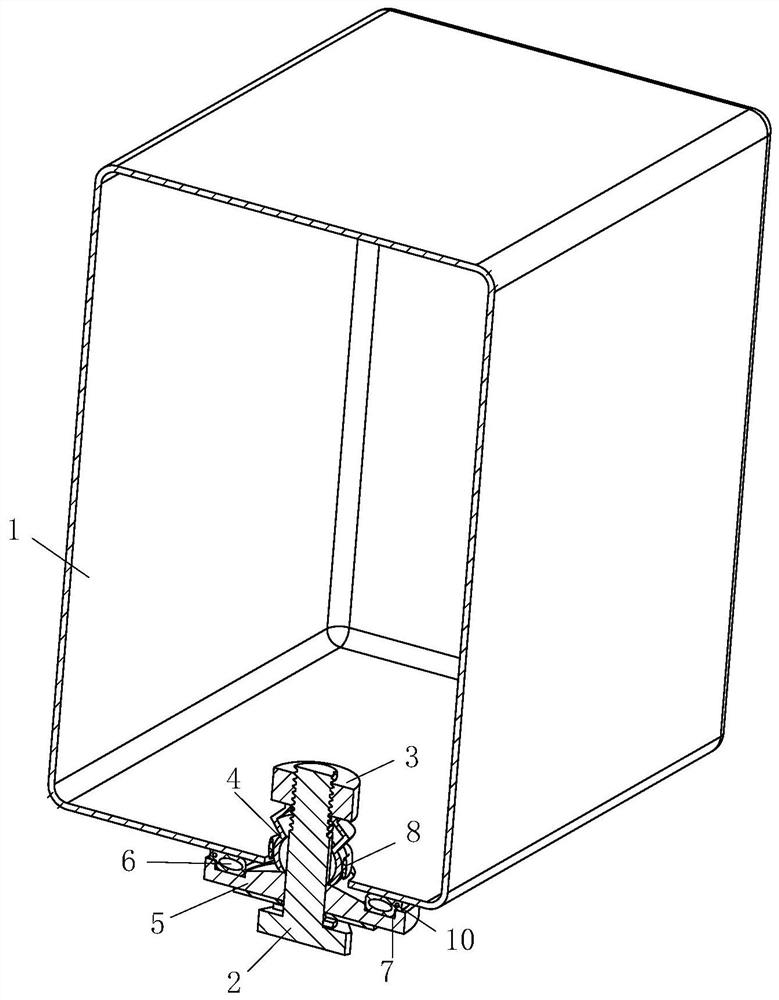

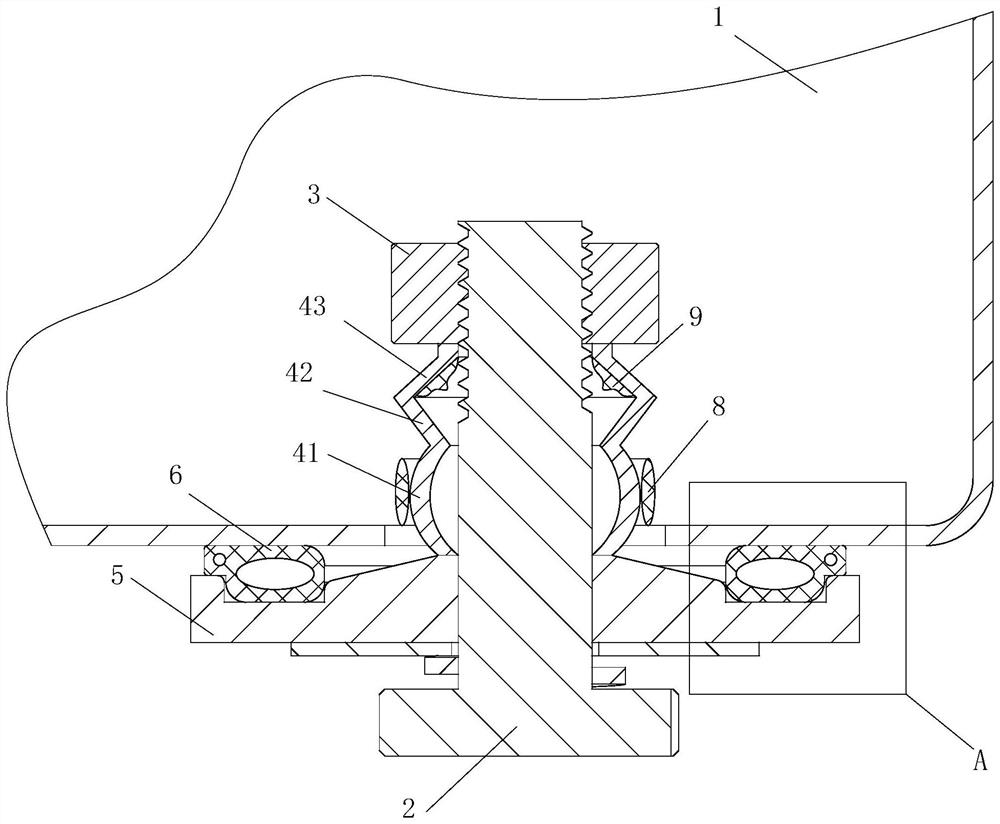

Installation structure of display device wall-mounted adapter and display device

ActiveCN105864605BStrong enoughSolve the installationMachine supportsCasings/cabinets/drawers detailsDisplay deviceEngineering

The invention is applicable to the field of display equipment and discloses a mounting structure for display equipment wall-mounting connectors and display equipment. The mounting structure for the display equipment wall-mounting connectors comprises a main case, a middle connecting component and the wall-mounting connectors arranged at the rear side part of the main case, wherein the middle connecting component is mounted at the rear side part of the main case in a fastening manner; and the wall-mounting connectors are mounted on the middle connecting component in a clamping and inserting way. According to the invention, connection between the wall-mounting connectors and the main case is indirectly realized through the middle connecting component mounted at the rear side part of the main case, so that the wall-mounting connectors are mounted without occupying assembly space of a main board, sufficient strength and mounting fastness and reliability of the wall-mounting connectors are effectively guaranteed. Therefore, mounting problems of the wall-mounting connectors in the large-size and large-weight display equipment are effectively solved, and a rear cover of the display equipment can be designed to be small enough so as to ensure attractiveness of the overall appearance of a product.

Owner:HEFEI HUIKE JINYANG TECH

Motor Bearing Anti-corrosion Structure and Brushless DC Motor

ActiveCN104467295BGuaranteed long-term effectivenessTo achieve a conductive connectionAssociation with grounding devicesElectric machineStructural engineering

The invention is applicable to the field of motors, and discloses a motor bearing anti-corrosion structure and a brushless DC motor. The motor bearing anti-corrosion structure includes a stator iron core, a conductive locking piece, a conductive nut assembly, a plastic-encapsulated casing and a cover fixed to the plastic-encapsulated casing. The first end cover at one end, the conductive nut assembly and the stator iron core are packaged and fixed in the plastic casing, and one end of the conductive nut assembly is connected with the stator iron core, and the other end is exposed outside the plastic casing. One end of the conductive locking piece is clamped outside the through hole, the other end passes through the through hole, and is screwed to the end of the conductive nut assembly exposed outside the plastic casing. The present invention realizes the conductive connection between the stator iron core and the first end cover through the cooperation of the conductive locking member and the conductive nut assembly, effectively preventing the occurrence of electrical corrosion of the bearing; The long-term reliability of the end cover conduction ensures the long-term effectiveness of the motor's anti-corrosion structure of the bearing.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

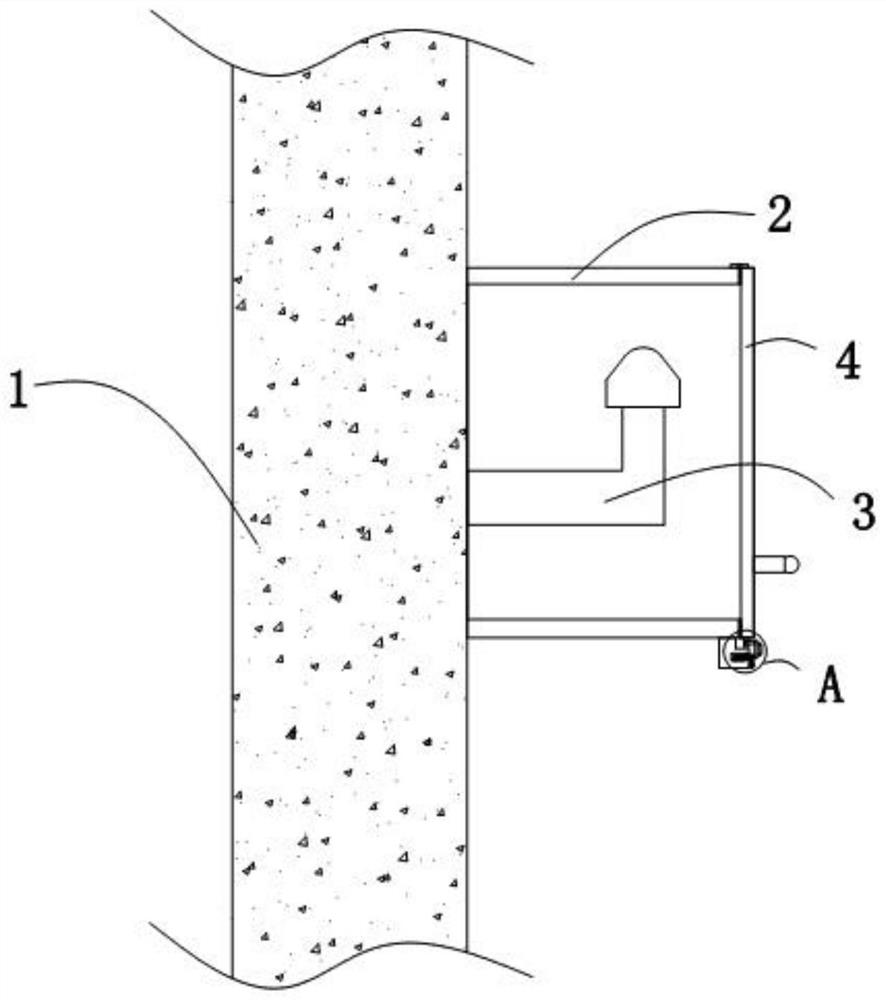

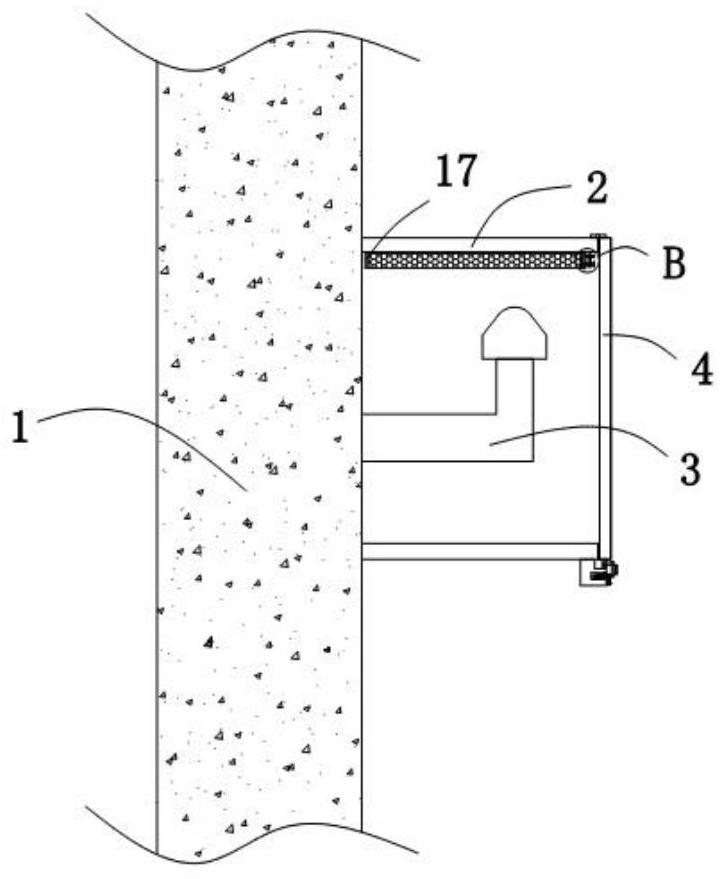

Building settlement observation point protection mechanism

InactiveCN112484694AEffective protectionAvoid damageMeasuring points markingHeight/levelling measurementObservation pointArchitectural engineering

The invention provides a building settlement observation point protection mechanism. The building settlement observation point protection mechanism comprises a wall body, a rectangular protection box,an embedded part, a connecting piece, a settlement observation point, an opening and closing door, a first rectangular block, an L-shaped fixing block, wherein the rectangular protection box is fixedly mounted on the outer wall of one side of the wall body; the embedded part is embedded in the wall body in advance; the connecting piece is in a horizontal state after being connected with the embedded part; the settlement observation point is in close fit and rotational connection with the connecting piece; the opening and closing door is arranged on one side of the rectangular protection box;the first rectangular block is fixedly mounted at the bottom part of the opening and closing door; and the L-shaped fixing block is fixedly mounted at the bottom part of the rectangular protection box. The rectangular protection box has the advantages that rectangular protection can be effectively conducted on the settlement observation point, corrosion or damage, caused by long-term exposure, ofthe settlement observation point is avoided, meanwhile, moisture in the rectangular protection box can be adsorbed, and the service life of the settlement observation point is prolonged.

Owner:陈烁

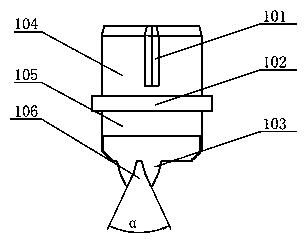

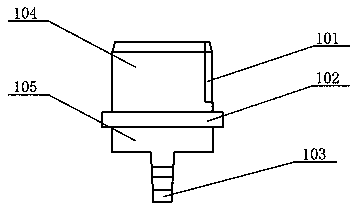

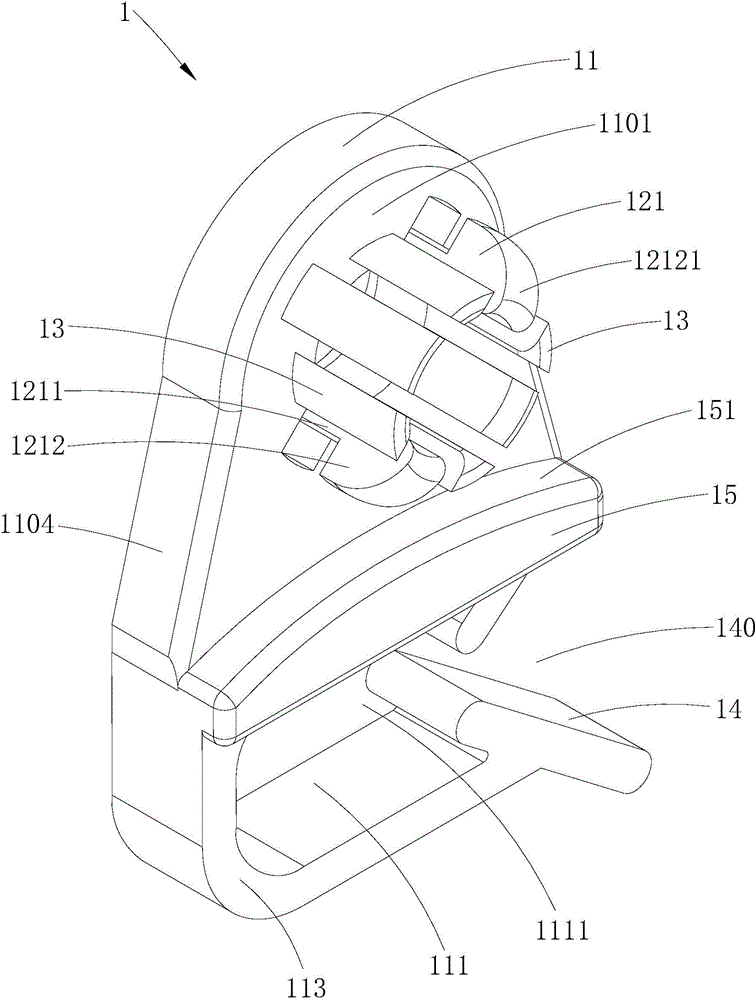

A riveting head structure for plunger steel ball riveting

The invention relates to a riveting head structure for riveting of a plunger steel ball. The riveting head structure is formed in the mode that an upper pressing body and a lower pressing body are connected into a whole. A flange is formed at the joint of the upper pressing body and the lower pressing body in an outwards extending mode in the circumferential direction. The upper pressing body is provided with an opening. The lower pressing body is provided with multiple bosses which are arranged at intervals. The riveting head structure is simple and convenient to install; since the upper pressing body is provided with the opening, a fastener can be in contact with the opening, and firmness and reliability of connection between the riveting head structure and a riveting machine are guaranteed; meanwhile, accurate locating between the riveting head structure and a pressing rod of the riveting machine can be realized through the flange; due to the arrangement of the bosses, the contact area between the riveting head structure and the steel ball can be maximized through a locating angle, damage to the surface of the steel ball is avoided, and riveting efficiency is also improved.

Owner:无锡创捷汽车部件有限公司

Motor outlet socket and motor for clothes dryer

ActiveCN104821684BRealize automated assemblyImprove the efficiency of outgoing operationsSupports/enclosures/casingsAssembly lineEngineering

The invention is applicable to the field of motors, and discloses a motor outlet seat and a motor for a clothes dryer, wherein the motor outlet seat includes a base plate with a wire slot and an elastic buckle provided on the base plate for buckle-connecting the end cover of the motor structure, the base plate has a first plate surface and a second plate surface set in opposite directions and a first side edge and a second side edge set in opposite directions, the elastic buckle structure is protruded on the first plate surface, and the wire groove is formed from the first plate surface. The board faces the second board and is arranged through, and the wire slot has a mounting notch running through the first side edge for the power cord to be snapped into and installed. In the present invention, the motor outlet seat is buckled and installed on the motor end cover, which is convenient for installation, which is beneficial to realize the automatic assembly of the motor outlet seat on the motor end cover and ensure the stability and reliability of the motor outlet seat on the motor end cover; and The power cord is snapped into the wire groove through the installation notch, and the assembly is simple, which is beneficial to realize the automatic assembly of the power cord and the outlet socket of the motor, and improves the operation efficiency of the outlet assembly operation of the motor.

Owner:FOSHAN WEILING WASHER MOTOR MFG

Plugging bolt for closed container side wall hole

InactiveCN112879405AReduce contact areaReduce bond strengthMaterial gluingNutsEngineeringStructural engineering

The invention belongs to the technical field of hardware, and particularly relates to a plugging bolt for a closed container side wall hole. The plugging bolt comprises a closed container, a stud, a nut, a deformation extrusion body, a pressing block and an outer sealing ring. One end of the nut of the plugging bolt is inserted into the closed container, the stud is rotated, the nut moves in the axial direction of the stud, then the distance between the nut and the pressing block is shortened, the deformation extrusion body is compressed and deformed, the deformation extrusion body is lengthened, the pressing block outside the closed container and the deformation extrusion body inside the closed container clamp the side wall of the closed container at the two sides, then the outer sealing ring is pressed, the deformation extrusion body can deform only by rotating the stud, the effect that the side wall of the closed container is clamped on the two sides to achieve the sealing effect is achieved, no requirement for the professional level of operators exists in the operation process, therefore, plugging work is simple, convenient and easy to implement, and due to the fact that the plugging bolt has no requirements for repairing personnel and equipment, the cost of repairing the hole is reduced.

Owner:郭澳

Knife components and food processors

ActiveCN109700340BRealize lateral limitRealize the vertical limitKitchen equipmentCentrifugal forceKnife blades

The invention is applicable to the field of household electrical appliances, and discloses a cutter assembly and a food cooking machine. The cutter assembly includes a cutter shaft and a cutter detachably mounted on the cutter shaft. Positioning holes are provided; the tool includes a base, a blade, a locking positioning member and an elastic member, the base is accommodated and positioned in the cavity, the locking positioning member is vertically connected to the blade and the base, and the elastic member includes a set at one end Inside the base, the other end extends laterally out of the base and is inserted into the positioning hole. The positioning rod and the two ends respectively abut the positioning rod and the first elastic member of the locking positioning member. The positioning rod is far away from the first elastic member. The end face is an inclined face or an arc face. In the present invention, when the cutter assembly rotates, the positioning rod will further protrude from the base and be inserted into the positioning hole under the action of centrifugal force, preventing the base from slipping and flying out of the cavity, and ensuring that the cutter is installed on the cutter shaft The stability and reliability of the tool, and the disassembly and assembly of the tool and the tool shaft are relatively convenient.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

Motor wire outgoing seat and motor for clothes dryer

ActiveCN104821684ARealize automated assemblyImprove the efficiency of outgoing operationsSupports/enclosures/casingsEngineeringMechanical engineering

Owner:FOSHAN WEILING WASHER MOTOR MFG

Waterproof sealing structure of plastic-sealed stator and bearing end cover and plastic-sealed motor

ActiveCN104539080BGood waterproof and sealing performanceGuaranteed solid reliabilitySupports/enclosures/casingsElectric machineryEngineering

The invention relates to the field of motors, and discloses a plastic package stator and bearing end cap waterproof sealing structure and a plastic package motor. The plastic package stator and bearing end cap waterproof sealing structure comprises a plastic package stator, a wire retaining clip, a waterproof sealing ring and a bearing end cap, wherein the plastic package stator is provided with an annular clamping flange with an installation notch, the wire retaining clip is installed in the installation notch, the bearing end cap is provided with an annular clamping groove matched with the annular clamping flange in a clamped and inserted mode, the annular clamping flange is provided with an axial end face, the wire retaining clip is provided with a wire clip top face flush with the axial end face, the annular clamping groove is provided with a bottom groove face, the waterproof sealing ring is elastically compressed between the axial end face and the bottom groove face, and a positioning groove allowing the waterproof sealing ring to be clamped and positioned is formed in the wire clip top face in a concave mode. The plastic package stator and bearing end cap waterproof sealing structure prevents influences of a needle insertion hole, a detection hole and a detachment notch which probably exist in the radial outer surface of the annular clamping flange on the sealing effect of the waterproof sealing ring, and achieves the aims of improving the waterproof sealing effect between the plastic package stator and the bearing end cap.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

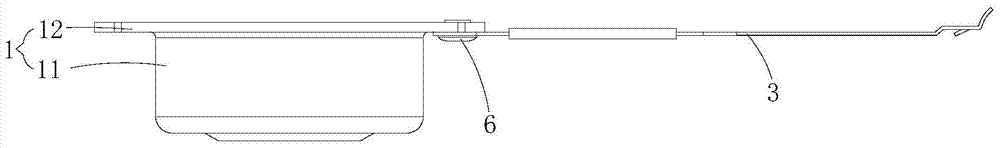

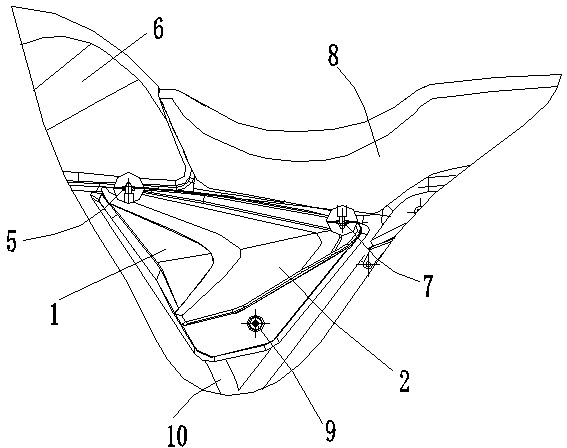

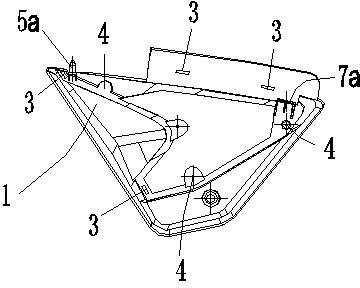

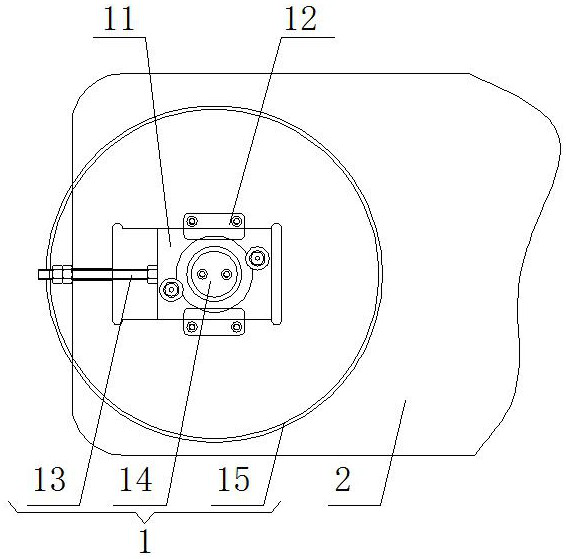

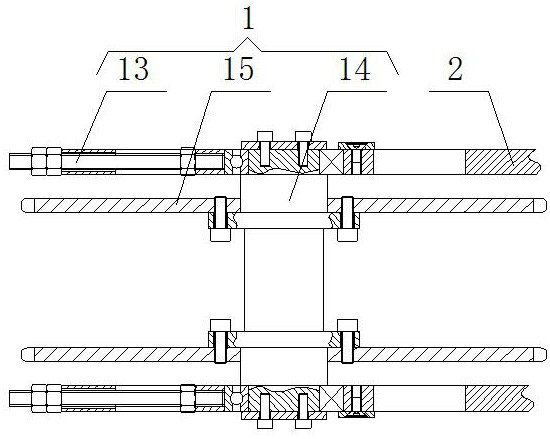

Mounting structure for side cover component of motorcycle

The invention discloses a mounting structure for a side cover component of a motorcycle. The side cover component is formed by assembling a side cover (1) and a side cover shield (2). The side cover (1) is connected with a fuel tank (6) which is positioned on the upper left of the side cover (1) through a first inserting element (5), connected with a seat cushion (8) which is positioned on the upper right of the side cover (1) through a second inserting element (7), and connected with a frame (10) on the inner side of the side cover (1) through mounting bolts (9). The upper right of the side cover (1) extends to form a transitional face (1a) which is engaged with the lower edge of the seat cushion (8). Longitudinal positioning is realized by the aid of the first inserting element and the second inserting element while transverse positioning is realized by the aid of the mounting bolts, and the mounting structure is firm and reliable in connection and convenient and rapid in insertion. Further, the transitional face arranged on the upper right of the side cover is engaged with the lower edge of the seat cushion after assembly, and accordingly the problem that an overlarge gap between the seat cushion and the side cover component affects the appearance of the whole motorcycle is effectively solved.

Owner:力帆科技(集团)股份有限公司

Waterproof sealing structure of plastic-encapsulated stator and bearing end cover and plastic-encapsulated motor

ActiveCN104539082BEasy to movePromote sheddingSupports/enclosures/casingsElastic compressionEngineering

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

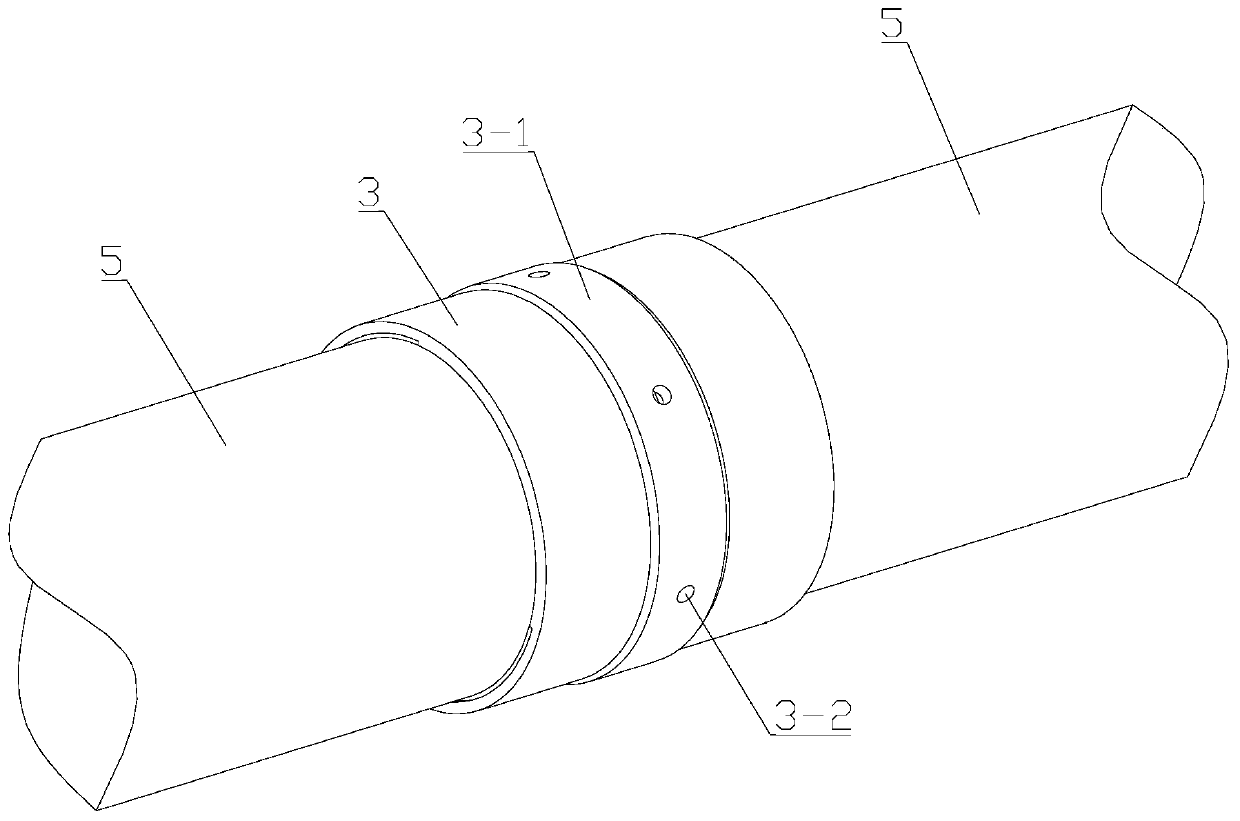

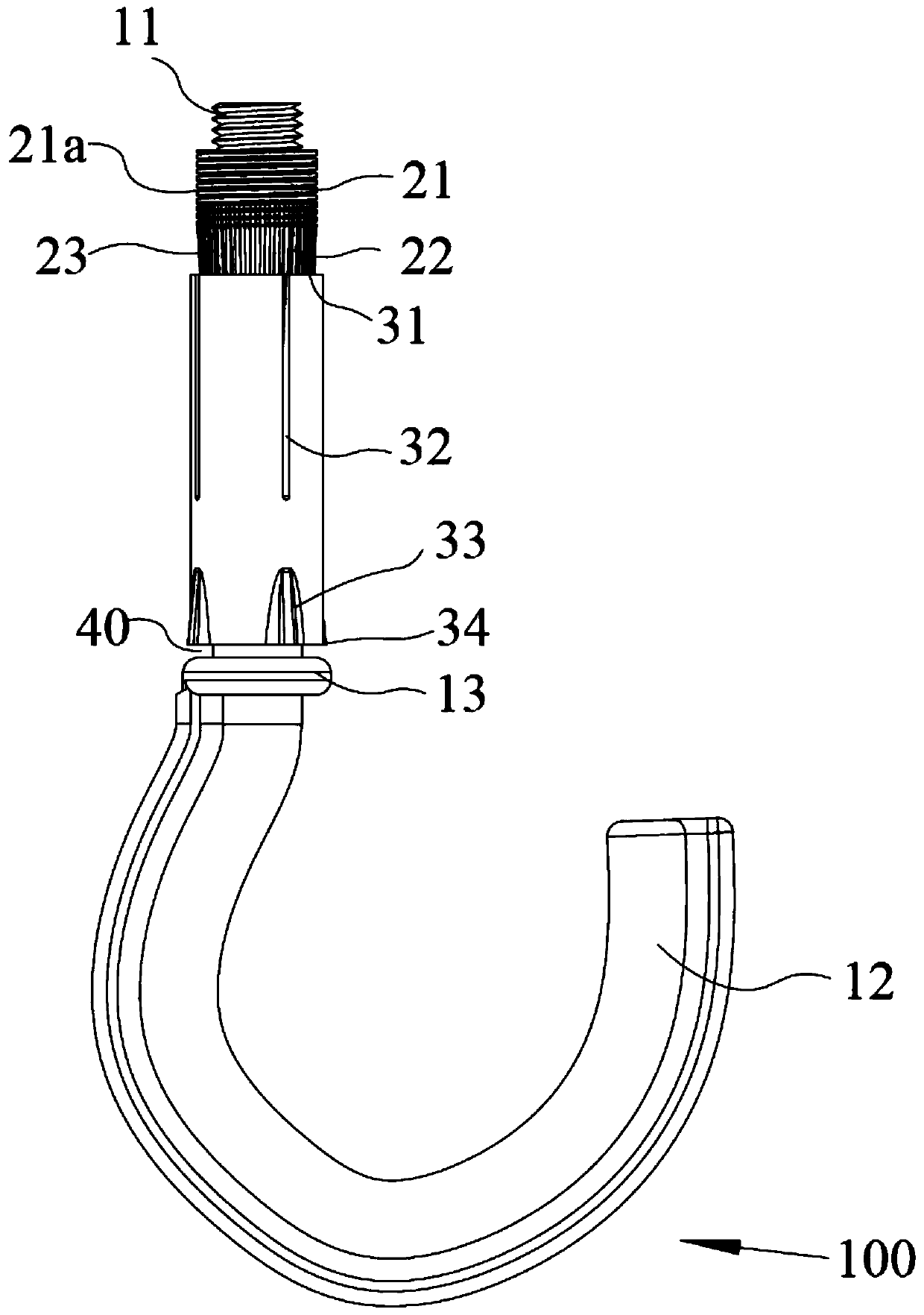

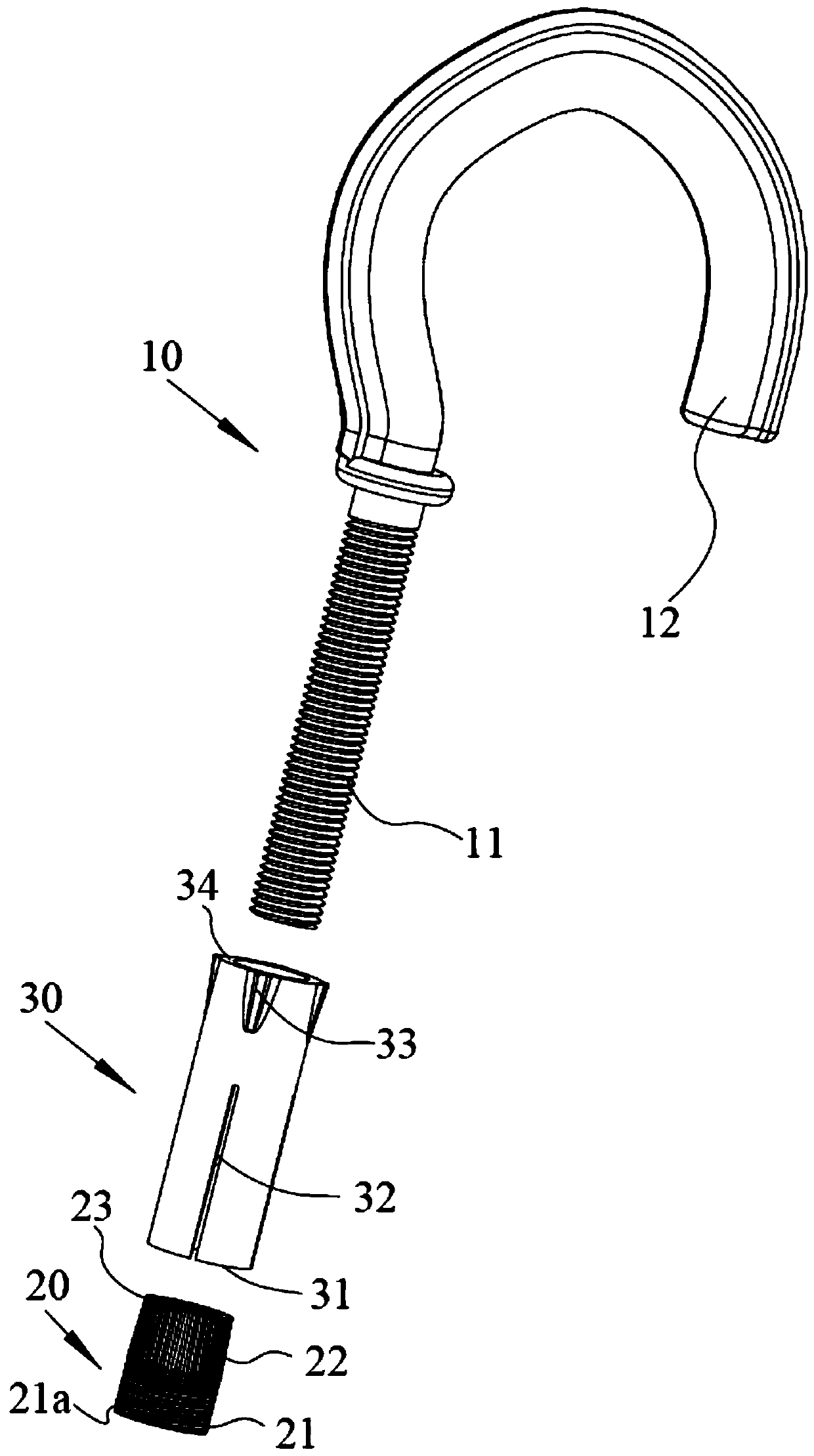

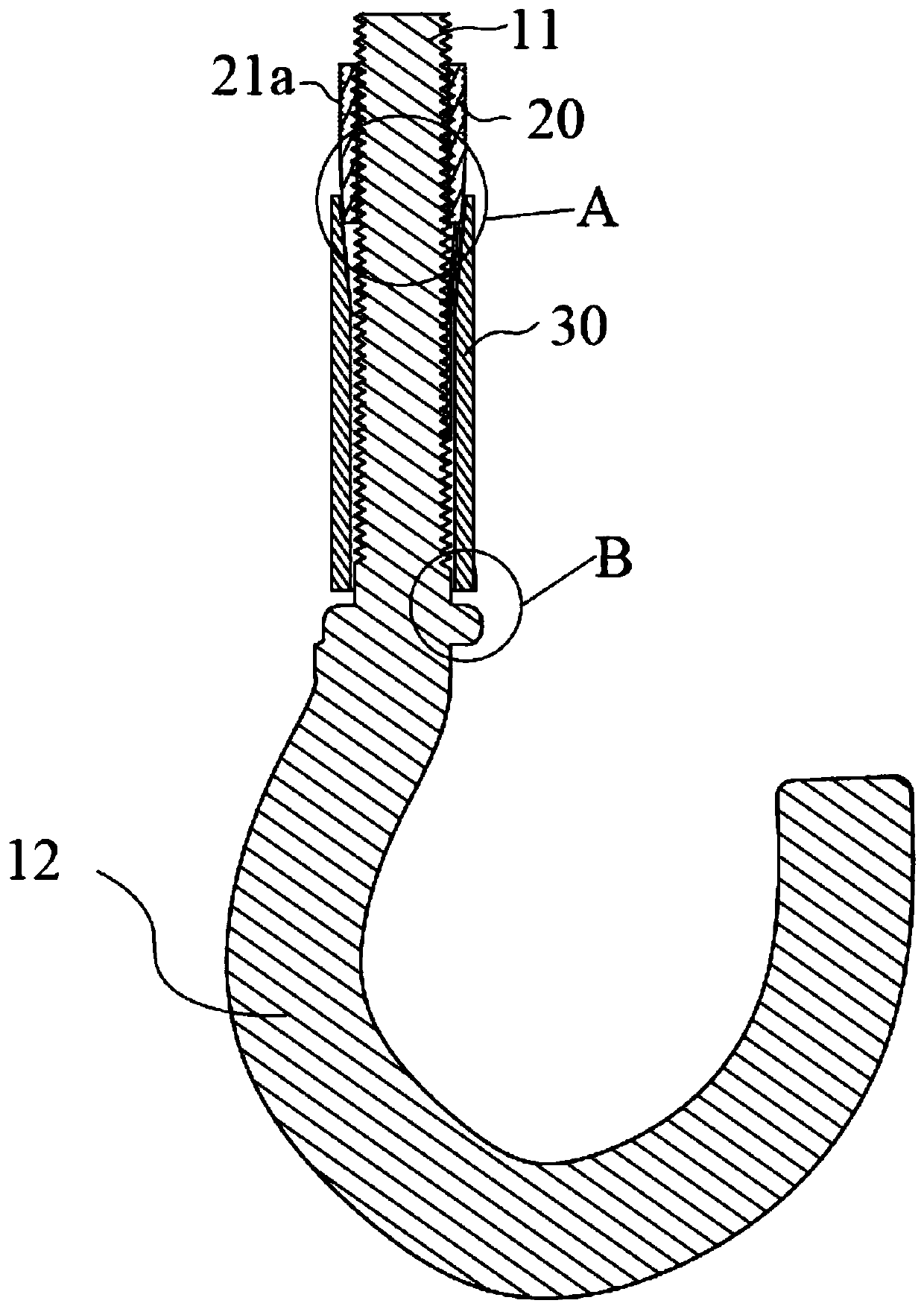

Quickly-and-fixedly-mounted sleeve, bolt and anchor rod mounting assembly

ActiveCN110700254AGuaranteed solid reliabilityCartridge expansion locking fit is safe and stableBulkheads/pilesScrew threadRock bolt

The invention discloses a quickly-and-fixedly-mounted sleeve, bolt and anchor rod mounting assembly. The assembly comprises an anchor rod and a bolt sleeve which are in inserted and threaded connection, wherein the anchor rod comprises a screw section and a convenient-to-install hook section which are integrally connected, the screw section sleeves and penetrates through an expansion mounting sleeve and is in fixed threaded connection with the inner circumference of the bolt sleeve, and meanwhile, the outer periphery of one end of the bolt sleeve is inserted and locked in an expansion port ofthe expansion mounting sleeve; and the screw section, the bolt sleeve and the expansion mounting sleeve are embedded in a building base surface, and the hook section is used for mounting an external load component. Through combination and installation of the anchor rod, the bolt sleeve and the expansion mounting sleeve of special structures, the assembly is simple in structure and quick and convenient to install on the basis of guaranteeing fixed mounting and reliability, and the assembly is especially suitable for the field of small and medium-sized load components.

Owner:常熟市双力金属制品有限责任公司

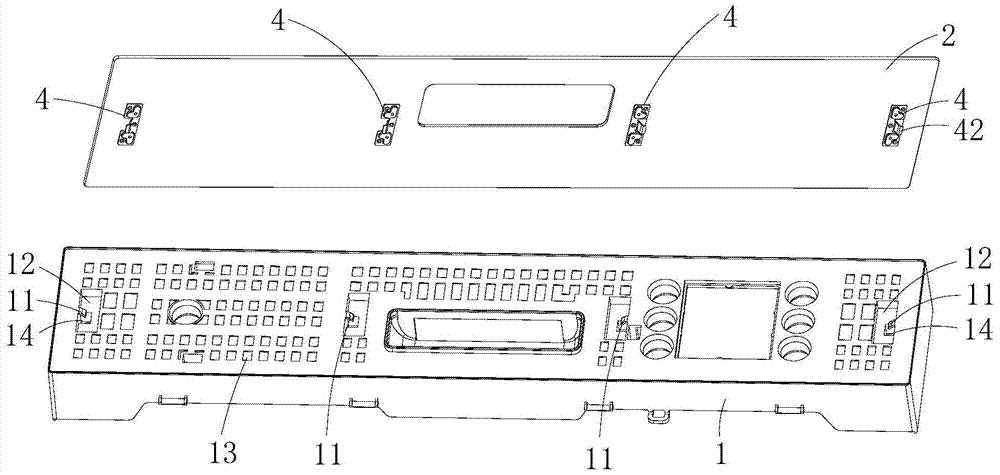

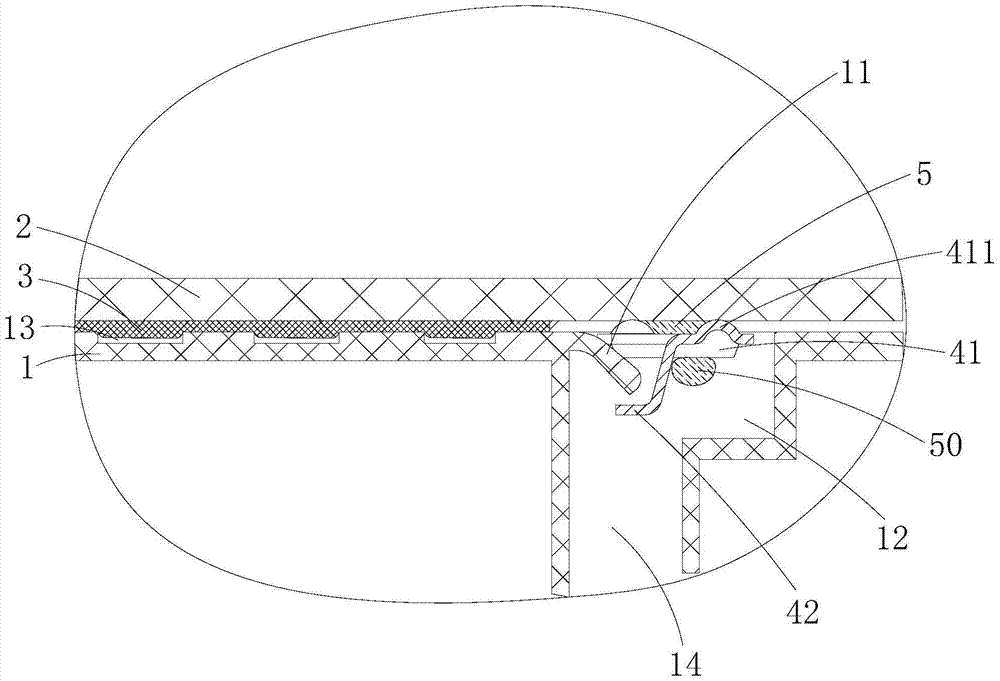

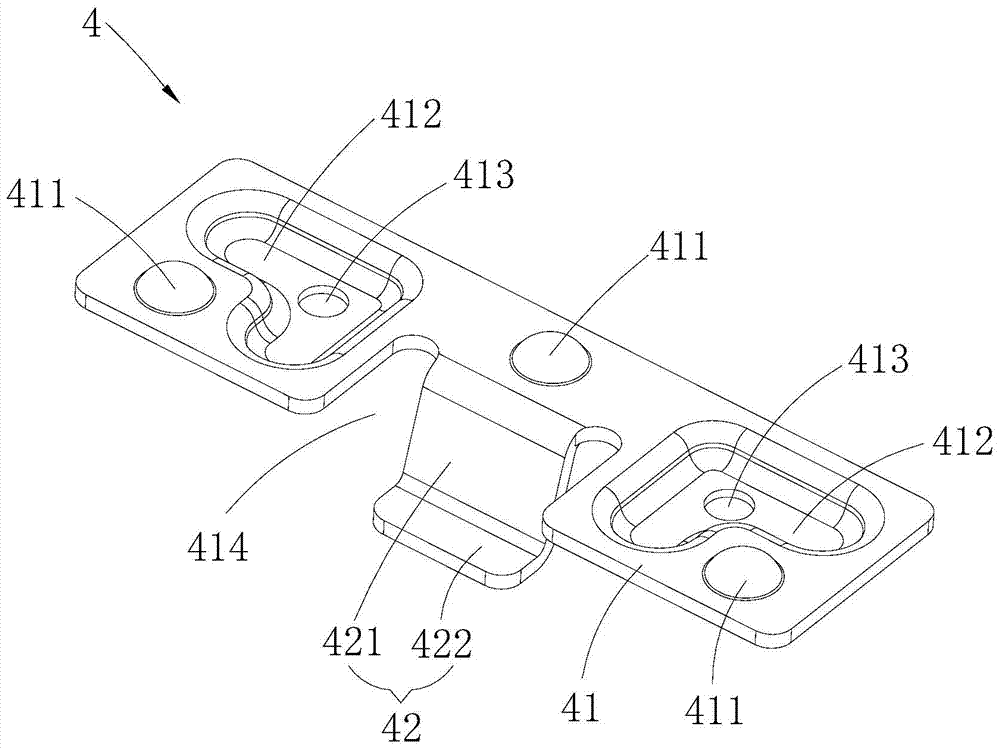

Installation structure of glass plate and dishwasher

ActiveCN104706297BGuaranteed solid reliabilityGuaranteed installation efficiencyTableware washing/rinsing machine detailsAdhesiveGlass sheet

The invention is applicable to the technical field of dishwashers, and discloses an installation structure of a glass plate and a dishwasher with the installation structure. The installation structure of a glass plate includes a control panel, a glass plate, a first adhesive and a connecting buckle The connecting fastener is fixed on the glass plate, and the control panel is provided with a buckle part corresponding to the position of the connecting fastener on the glass plate. The glass plate is bonded to the control panel by the first adhesive and passed The fastener buckle is connected with the buckle part. In the present invention, the glass plate is bonded and fixed on the control panel through the first adhesive, and the glass plate is buckled and fixed on the control panel through the connecting fastener. In this way, the glass plate can be installed on the control panel. The effect of double fixation is obtained, thereby effectively ensuring the stability and reliability of the installation of the glass plate on the control panel. At the same time, since the operation process of the buckle connection is simple, it effectively ensures the installation efficiency of the glass plate parts and is beneficial to mass assembly and production of the glass plate parts.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Waterproof sealing structure of plastic-sealed stator and bearing end cover and plastic-sealed motor

ActiveCN104539081BGood waterproof and sealing performanceGuaranteed solid reliabilitySupports/enclosures/casingsElectric machineStructural engineering

The invention relates to the field of motors, and discloses a plastic package stator and bearing end cap waterproof sealing structure and a plastic package motor. The plastic package stator and bearing end cap waterproof sealing structure comprises a plastic package stator, a bearing end cap and a waterproof sealing ring, wherein the plastic package stator is provided with an annular clamping flange, the bearing end cap is provided with an annular clamping groove matched with the annular clamping flange in a clamped and inserted mode, the annular clamping flange is provided with an axial end face towards the bearing end cap in the axial direction of the plastic package stator, the annular clamping groove is provided with a bottom groove face towards the plastic package stator in the axial direction of the plastic package stator, the waterproof sealing ring is elastically compressed between the axial end face and the bottom groove face, and a positioning groove allowing the waterproof sealing ring to be clamped, inserted and positioned is formed in the axial end face in a concave mode. The plastic package stator and bearing end cap waterproof sealing structure prevents influences of a needle insertion hole, a detection hole and a detachment notch which probably exist in the radial outer surface of the annular clamping flange on the sealing effect of the waterproof sealing ring, and achieves the aims of improving the waterproof sealing effect between the plastic package stator and the bearing end cap.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

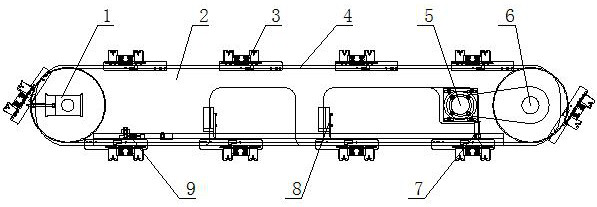

Hand bag conveying device

PendingCN114435867AGuaranteed stabilityGuaranteed reliabilityConveyorsControl engineeringProcess engineering

The invention discloses a hand bag conveying device which comprises a chain tensioning device, a rack, a clamping device, a conveying chain, a driving mechanism, a driving chain wheel, a bag clamping driving air cylinder, a station positioning device and a bag loosening driving device. A chain wheel in the chain tensioning device is connected with a driving chain wheel through a conveying chain, the driving chain wheel is connected with a synchronous belt wheel in the driving mechanism through a synchronous belt, clamping devices are arranged on the conveying chain, and a bag loosening driving device, a station positioning device and a bag clamping driving air cylinder are sequentially arranged at the lower end of the machine frame from left to right. The hand bag multi-station circulating device is ingenious in design and small in occupied space, multi-station simultaneous circulating operation of hand bags can be achieved, manual operation is avoided, the labor cost is saved, the working efficiency is greatly improved while the processing accuracy of the hand bags is guaranteed, and therefore the automatic operation level and efficiency are achieved, and development of the packaging equipment industry is facilitated.

Owner:河南新印智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com