Waterproof sealing structure of plastic-encapsulated stator and bearing end cover and plastic-encapsulated motor

A technology for plastically sealing stators and bearing end covers, which is applied in the direction of electrical components, electromechanical devices, and electric components, can solve problems such as poor waterproof and sealing effects, prevent easy displacement or falling off, improve assembly efficiency, and ensure stability and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

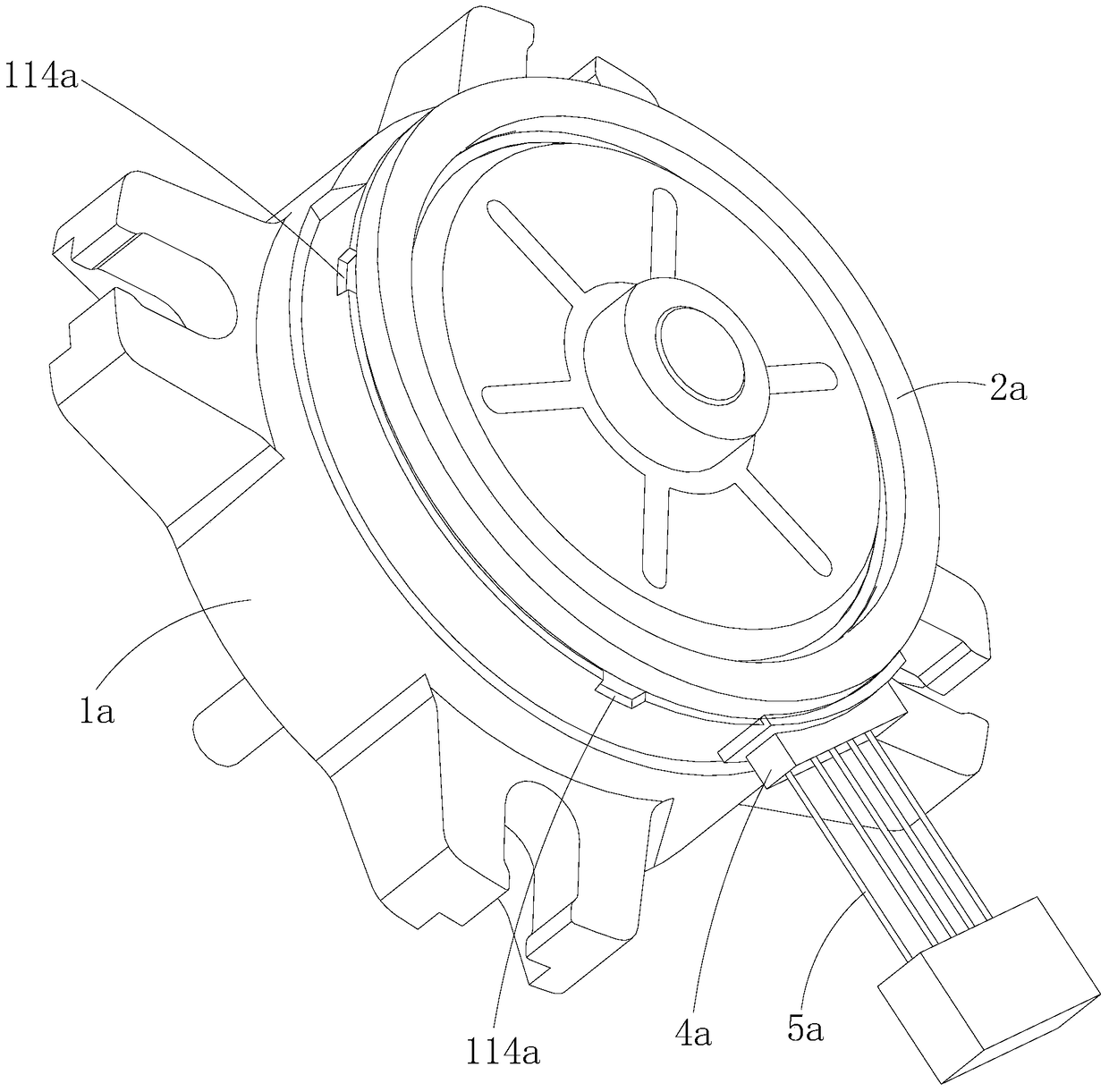

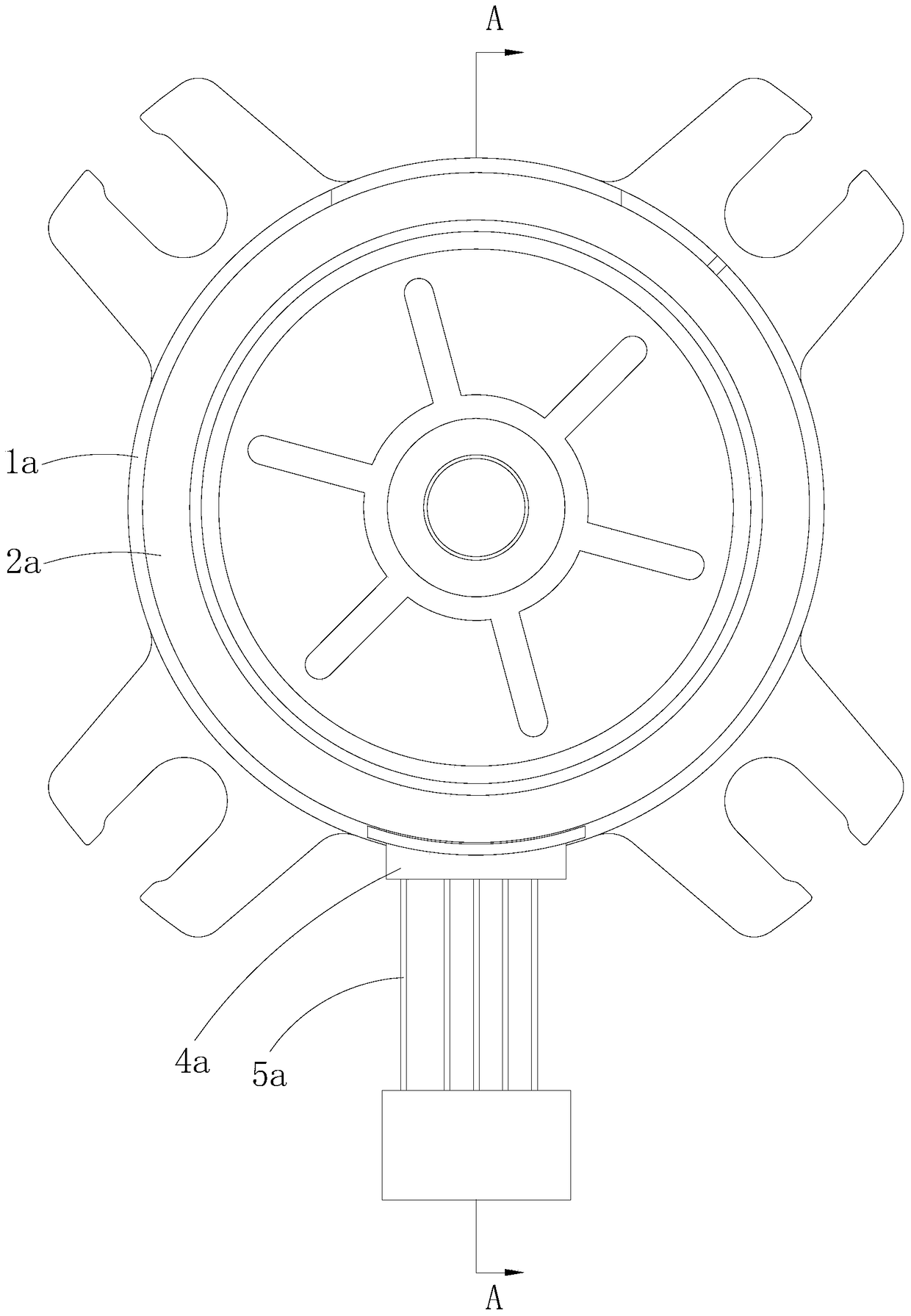

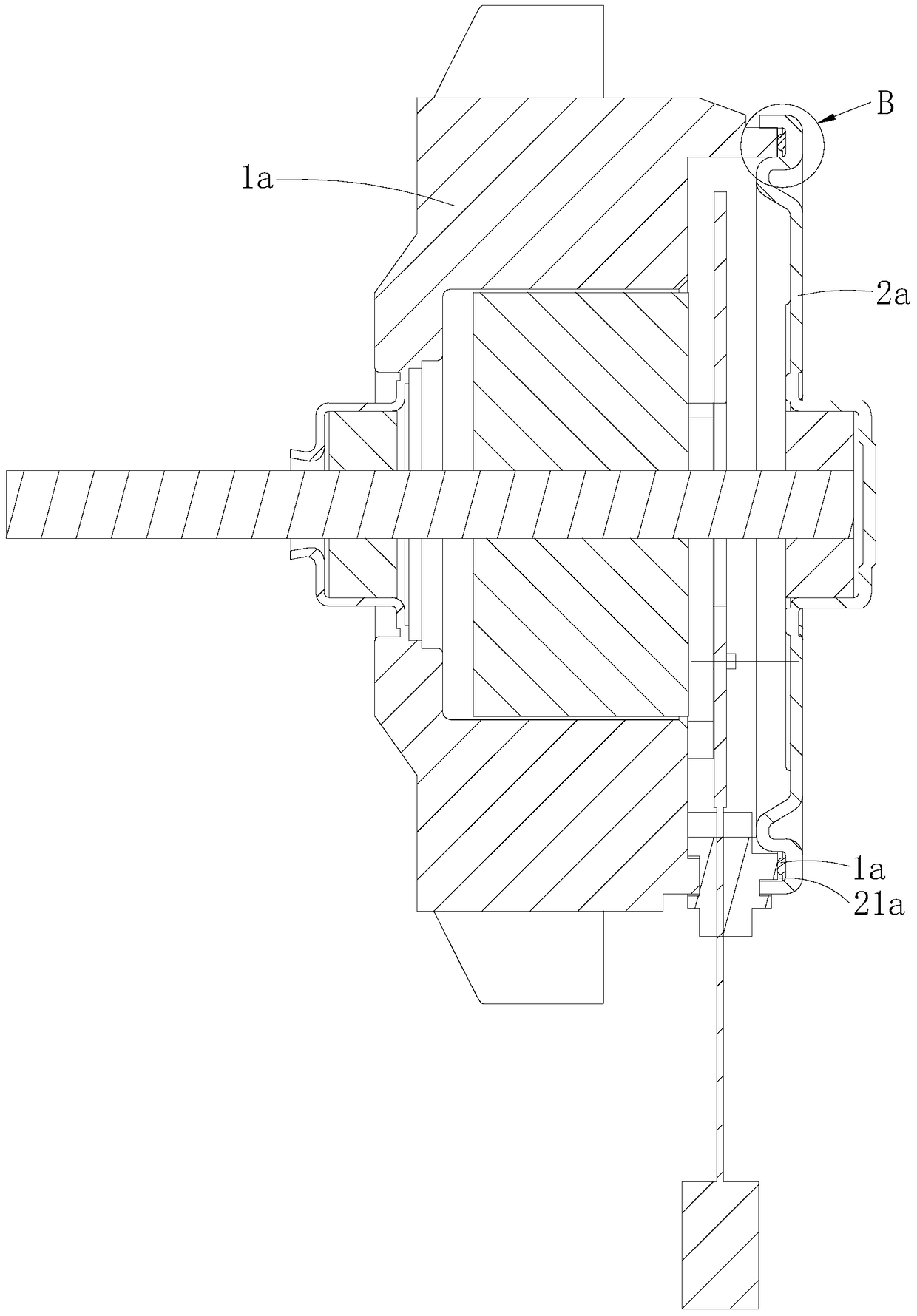

[0033] Such as Figure 1-8As shown, the waterproof sealing structure of the plastic-encapsulated stator and the bearing end cover provided by the first embodiment of the present invention includes the plastic-enclosed stator 1a and the bearing end cover 2a arranged at the outer end of the plastic-enclosed stator 1a, and the plastic-enclosed stator 1a is provided with an annular locking protrusion. edge 11a, the bearing end cover 2a is provided with an annular slot 21a that fits with the annular locking flange 11a, and the annular locking flange 11a has an axis facing the bearing end cover 2a along the axial direction of the plastic-sealed stator 1a. Towards the end face 111a, the radially inner surface 113a facing the central axis of the plastic-encapsulated stator 1a along the radial direction of the plastic-enclosed stator 1a, and the radially outer surface 112a facing away from the central axis of the plastic-enclosed stator 1a along the radial direction of the plastic-enclo...

Embodiment 2

[0042] The main difference between this embodiment and Embodiment 1 is that the shape of the top membrane part is different, specifically, as Figure 9 As shown, in the waterproof sealing structure of the plastic-sealed stator and bearing end cover and the plastic-sealed motor provided in this embodiment, the protruding sealing surface 321b is the second arc surface protrudingly provided at the middle position of the top membrane part 32b, and the two auxiliary mating surfaces 322b are two third arcuate surfaces extending smoothly along both sides of the protruding sealing surface 321b respectively. Same as Embodiment 1, the waterproof sealing membrane 3b in this embodiment includes a bottom membrane portion 31b attached to the bottom groove surface 211b and a top membrane portion 32b facing the axial end surface 111b, and the top membrane portion 32b also includes A protruding sealing surface 321b and two auxiliary mating surfaces 322b respectively located on both sides of th...

Embodiment 3

[0046] The main difference between this embodiment and Embodiment 1 and Embodiment 2 is that the shape of the top membrane part is different, specifically, as Figure 10 As shown, in the waterproof sealing structure of the plastic-sealed stator and the bearing end cover and the plastic-sealed motor provided in this embodiment, the top membrane part 32c includes two protruding sealing surfaces 321c arranged at intervals along the radial direction of the plastic-sealed stator and one The auxiliary mating surface 322c is radially located between the two protruding sealing surfaces 321c. In this embodiment, the auxiliary mating surface 322c is located at the middle position of the top membrane part 32c along the radial direction of the plastic-encapsulated stator, and the two protruding sealing surfaces 321c are respectively abutted against the inner groove surface of the annular clamping groove 21c attached to the bearing end cover 2c 213c and the outer groove surface 212c, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com