Waterproof sealing device for motor casing outlet

A waterproof sealing and wire outlet technology, which is applied in the directions of electromechanical devices, casings/covers/supports, electrical components, etc., can solve the problems affecting the service life of the motor, the vehicle performance, the deformation of the rubber injection head, and the failure of the waterproof effect. Good waterproof sealing effect, ensuring sealing and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

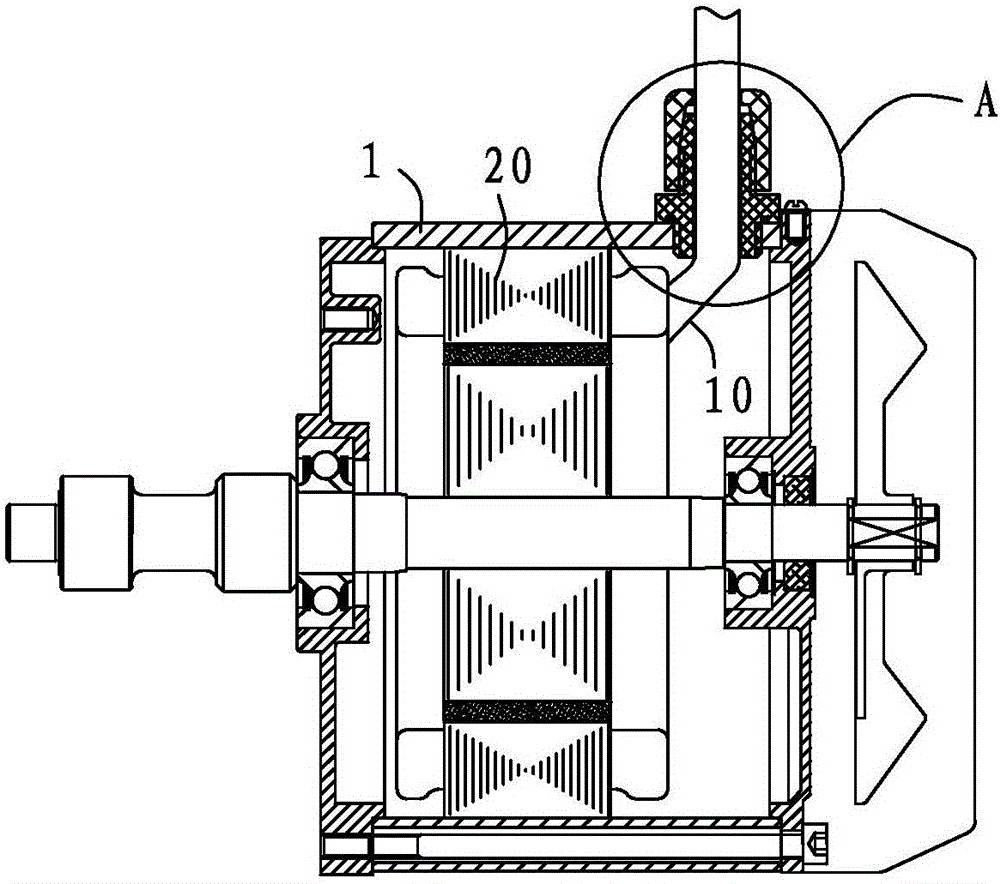

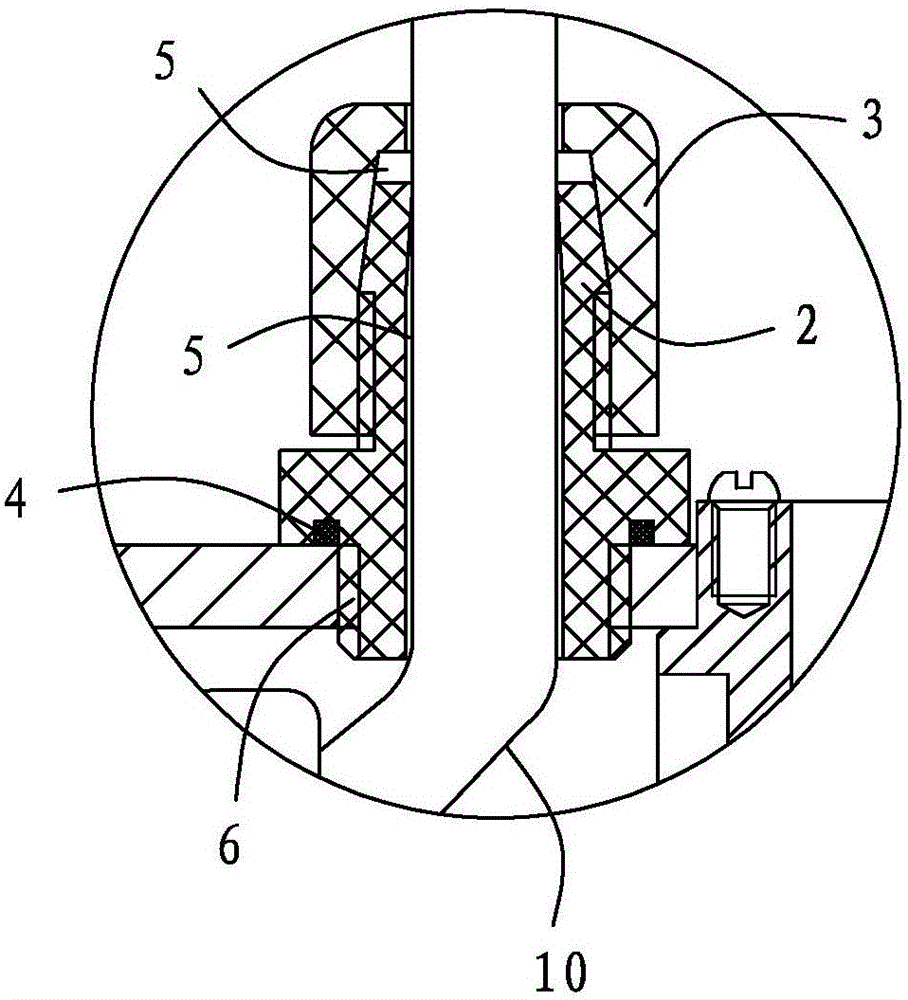

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] refer to figure 1 with figure 2 : A waterproof sealing device for the outlet of the motor casing, including a casing 1, a threaded joint 2, a nut 3 and a sealing ring 4, the outer surface of the casing 1 is provided with a threaded hole, and one end of the threaded joint 2 is provided with a thread, which is connected with the threaded hole Cooperate, the nut 3 cooperates with the other end of the threaded joint 2, the sealing ring 4 is arranged on the side where the threaded joint 2 cooperates with the threaded hole, and the threaded joint 2 and the nut 3 are both provided with through holes 5 . During use, the motor 20 is installed inside the housing 1 , and the motor leads 10 pass through the threaded joint 2 and the through hole 5 of the nut 3 , and the outlet of the lead 10 is sealed by the cooperation of the threaded joint 2 and the threaded ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com