Wall surface rear-mounted type waterproof sleeve assembly and wall body structure with wall surface rear-mounted type waterproof sleeve assembly

A waterproof sleeve and assembly technology, applied in the direction of pipes/pipe joints/fittings, pipes, passing elements, etc., can solve the problems of poor waterproof effect and cumbersome construction procedures, and achieve simple and fast fixing, good waterproof sealing effect, avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

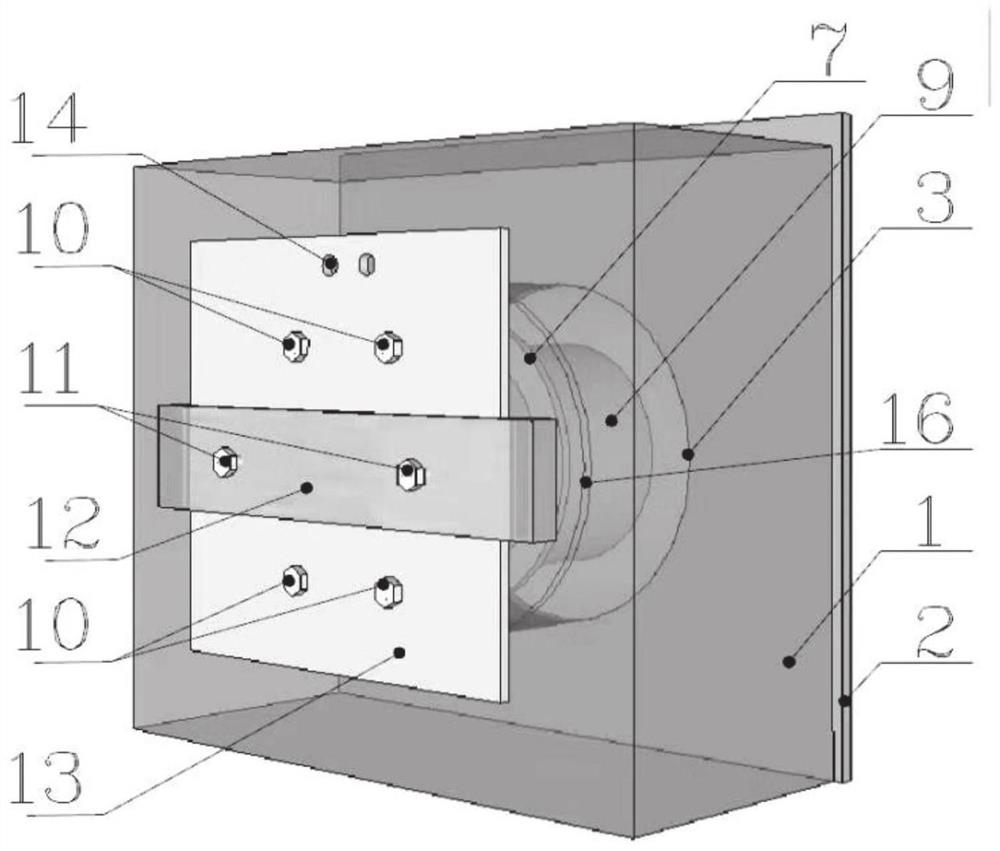

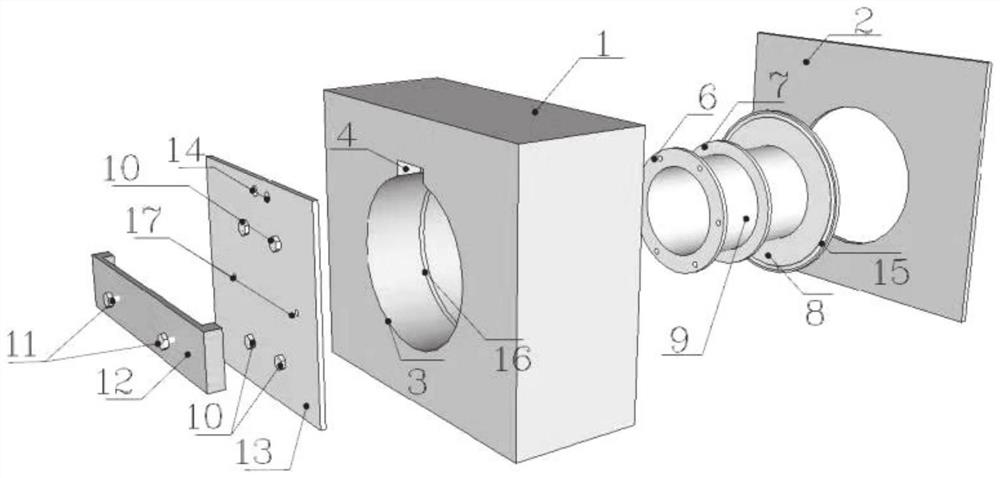

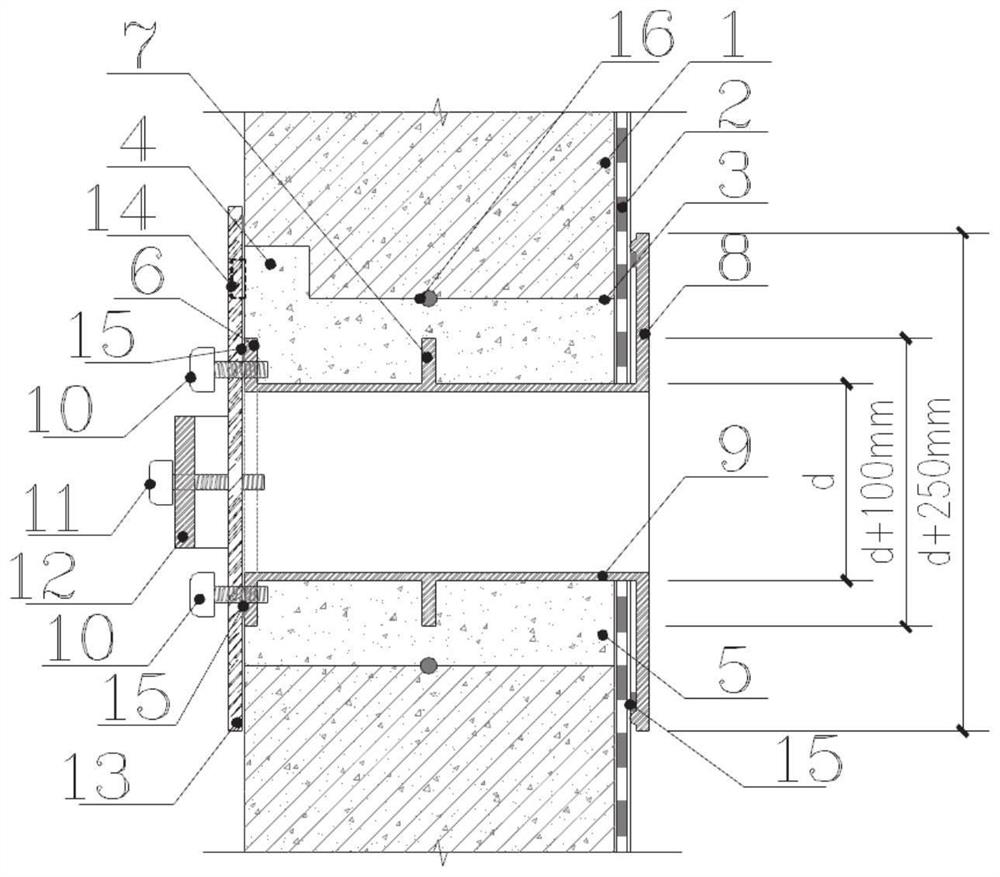

[0034] Such as Figure 1~5 As shown, the outer side of the existing wall 1 is pasted with an outer wall waterproof membrane layer 2 to meet the waterproof requirements of the wall. When adding a casing, it is necessary to drill a hole slightly larger than the size of the casing, and at the same time remove the waterproof membrane in the same range to form a wall opening 3, in order to ensure that the filled concrete can be properly injected into the hole after the casing is arranged 5 , it is necessary to open a 50-100mm grouting hole 4 above the inner side of the wall opening 3.

[0035] In this embodiment, the diameter of the casing 9 is d, the diameter of the flange 6 and the wing disc 7 is (d+100) mm, the diameter of the cover plate 8 is (d+250) mm, the flange 6, the wing disc 7, The cover plate 8 and the casing 9 are integrally formed metal components, which are placed in the casing hole 3 pre-opened in the wall from the outdoor to the indoor direction. On the indoor si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com