Mounting structure for side cover component of motorcycle

A mounting structure and motorcycle technology, applied in bicycle accessories, transportation and packaging, weather guards, etc., can solve the problems of affecting the quality of the vehicle's external hanger, inconvenient assembly and maintenance, and scratches on the side cover components, etc., to achieve convenient plugging Fast, convenient disassembly and assembly, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

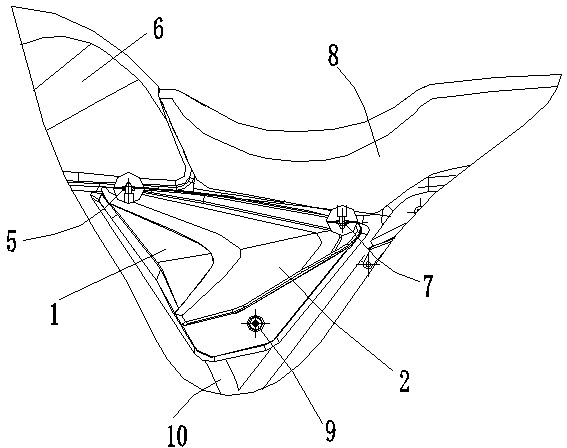

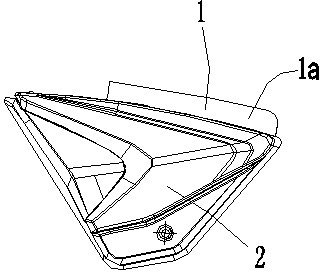

[0014] Such as figure 1 The motorcycle side cover assembly shown is assembled from a side cover 1 and a side cover guard 2 . Side cover guard 2 is covered on the outside of side cover 1, and side cover guard 2 is smaller than the outline dimension of side cover 1, makes the upper edge and the lower edge of side cover 1 exposed outside side cover guard 2. The side cover 1 is connected with the fuel tank 6 located at the upper left side of the side cover 1 through the first plug-in member 5 , connected with the seat cushion 8 located at the upper right side of the side cover 1 through the second plug-in member 7 , and connected with the seat cushion 8 at the upper right side of the side cover 1 through the mounting bolt 9 . 1 inner side frame 10 is connected.

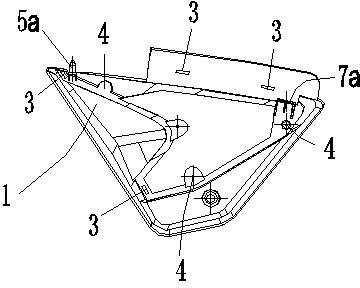

[0015] combine figure 2 -4, it can be seen that the side cover 1 and the side cover shield 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com