A riveting head structure for plunger steel ball riveting

A technology of riveting head and steel ball, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of damaged steel ball riveting, indenter cannot change the structure, and is not firm, so as to avoid damage, simple structure, The effect of improving riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

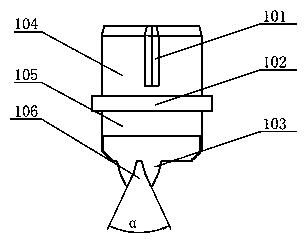

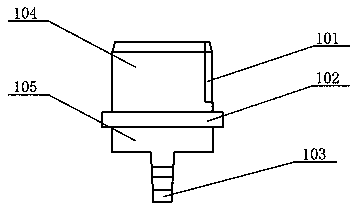

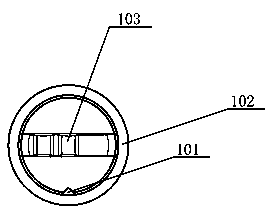

[0018] Such as figure 1 , figure 2 As shown, a riveting head structure for plunger steel ball riveting, which is formed by connecting an upper pressing body 104 and a lower pressing body 105, and is located at the joint of the upper pressing body 104 and the lower pressing body 105 outward along the circumferential direction The flange 102 is extended to form an opening 101 on the upper pressing body 104 , and the opening 101 is vertically arranged on the upper pressing body 104 . A plurality of bosses 103 arranged at intervals are formed on the lower pressing body 105 . The flange 102 , the upper pressing body 104 and the lower pressing body 105 are all circular. The longitudinal section of the bosses 103 is conical, and the slopes of the bosses 103 form a positioning angle α for abutting against the surface of the plunger steel ball....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com