Additive manufacturing device composite powder compacting and spreading device and method

A technology of additive manufacturing and powder spreading device, which is applied in the direction of improving process efficiency and energy efficiency, can solve the problems of poor compactness of three-dimensional formed products and affect the mechanical properties of three-dimensional formed products, and achieve stable distribution and arrangement of powder gaps, reduce Small rebound, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

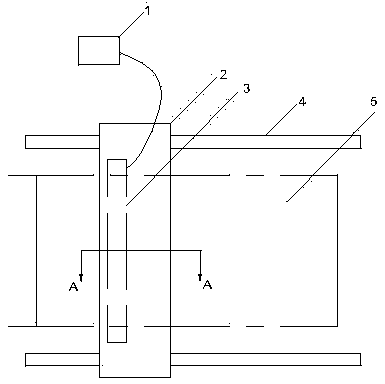

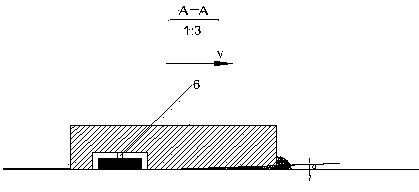

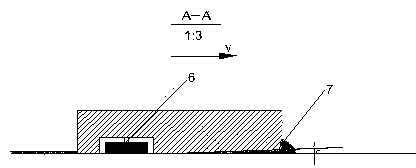

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] The core of the compound compacting powder spreading device of the additive manufacturing equipment of the present invention is to replace the powder spreading roller in the prior art with a composite compacting powder spreading device that spreads powder on an inclined surface and vibrates while spreading powder, so that the powder material can be affected To better compaction, thereby improving the compactness of three-dimensional molding products. Based on this inventive concept, the inventor finally provided a composite compacting powder spreading device for additive manufacturing equipment after creative work, including a pressure powder spreading device, which has a coating surface with a certain inclined angle, and uses for laying powder; and a vibration system for vibratory compaction of laid powder.

[0037] In a spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com