Lead screw lead accuracy detection device and detection head device thereof

A technology of precision detection and screw rod, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of automatic pressing of the probe, high quality requirements of workers, and low detection efficiency, so as to achieve accurate detection and improve the accuracy of inspection , Easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

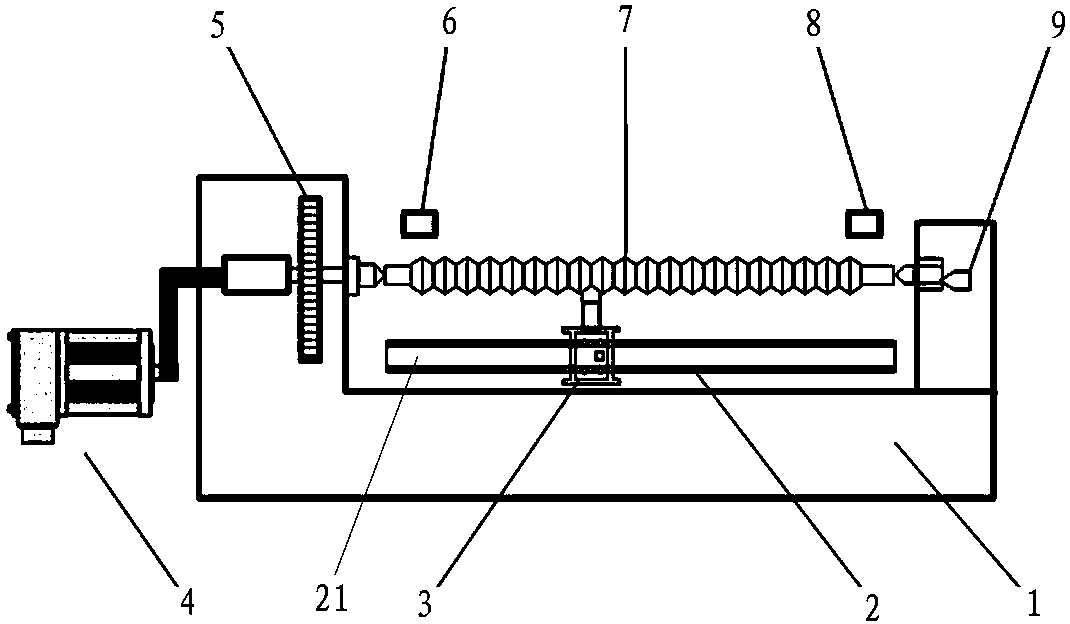

[0023] refer to figure 1 As shown, the screw lead accuracy detection device of an embodiment includes: a mechanical part, a motion control part, a data acquisition part, and a computer, wherein:

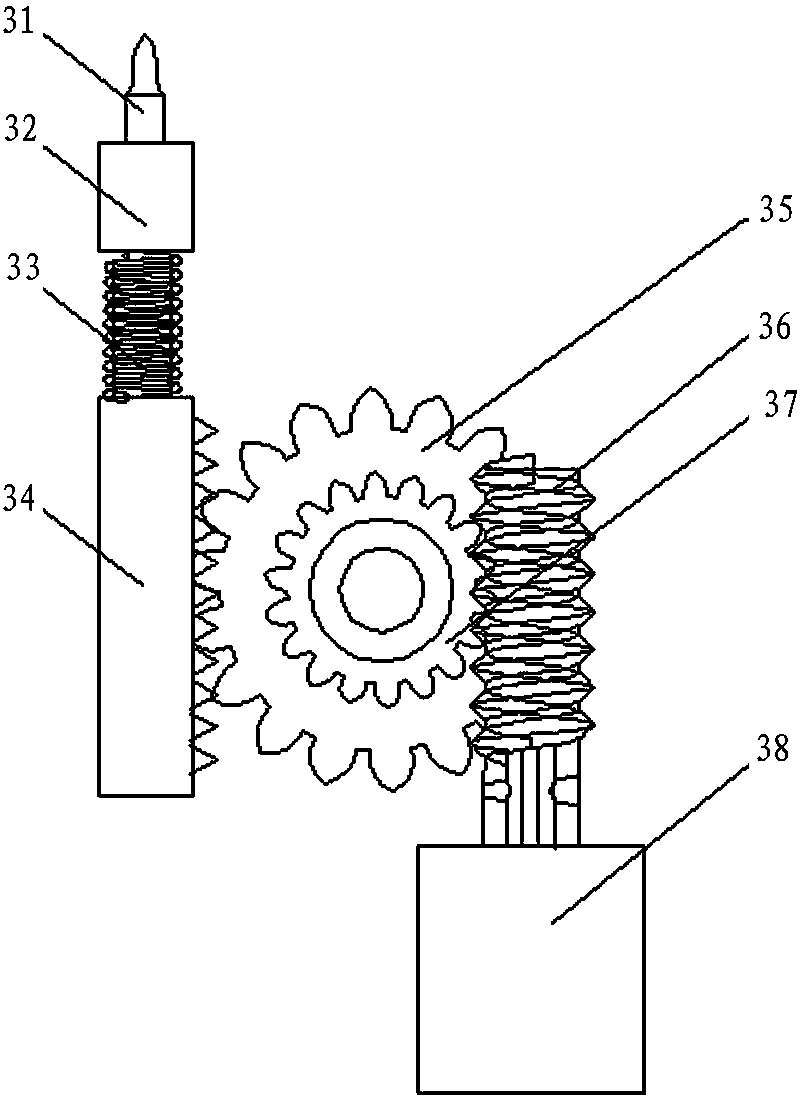

[0024] The mechanical part includes: instrument main frame 1, detection track 2 installed on the instrument main frame 1, linear scale 21 installed on the detection track 2, installed on one side of the instrument main frame 1 to detect the measured wire The circular grating pair 5 of the rotation angle of the rod 7, and the measuring head device 3 that is installed on the detection track 2 and can slide along the track. In addition, in order to be in place when testing, a left limit sensor 6 and a right limit sensor 8 are installed on the main frame 1 of the instrument close to the two ends of the screw mandrel 7 to be tested, and a limit sensor 8 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com