Plate glass transferring device

A flat glass and conveying device technology, used in glass manufacturing equipment, glass transportation equipment, packaging, etc., can solve the problems of reduced inspection accuracy, limited exhaust volume, and inability to perform accurate measurements, to improve inspection accuracy and prevent excessive floating. The effect of accurately measuring the defective product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

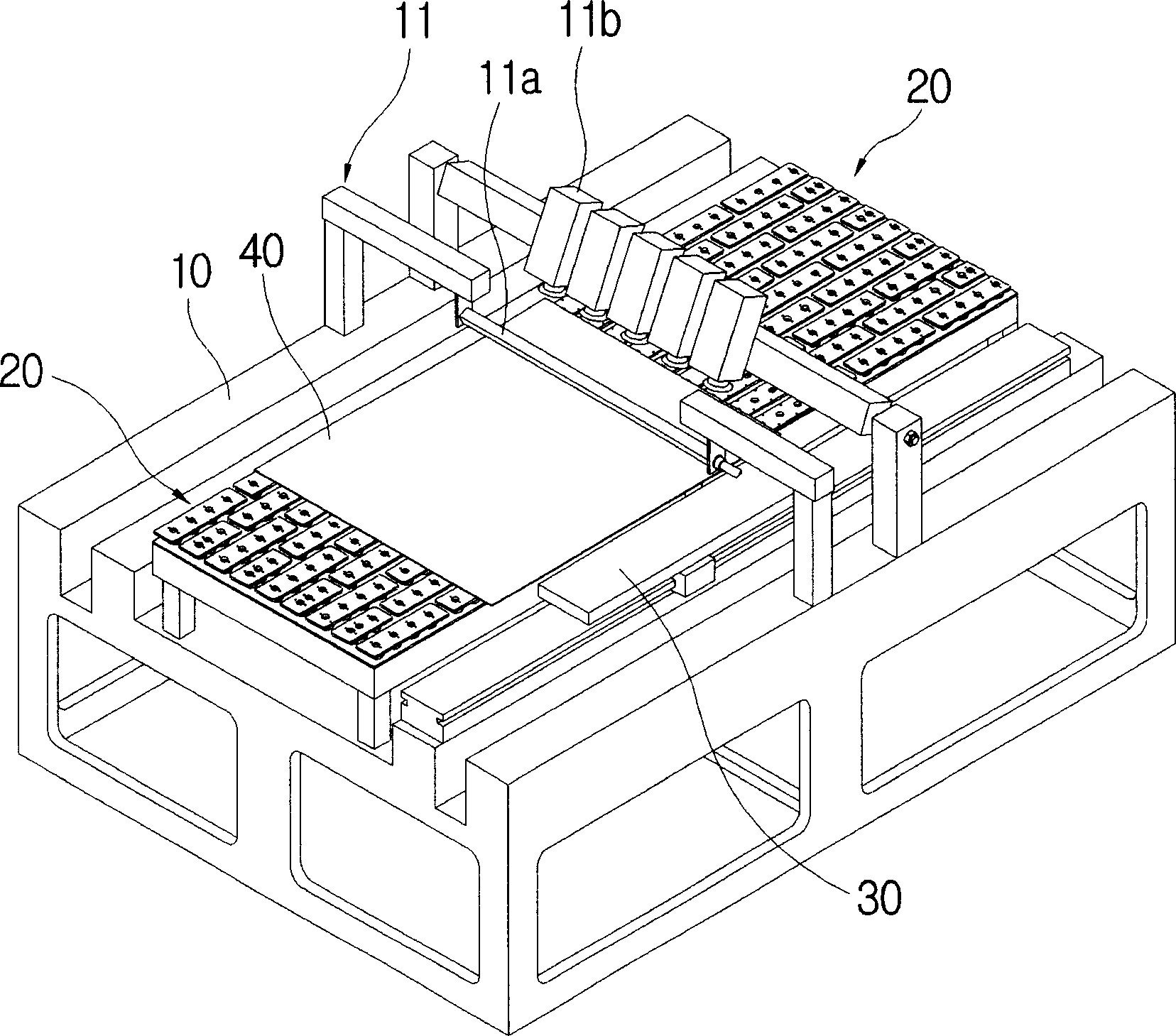

[0032] Hereinafter, specific embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

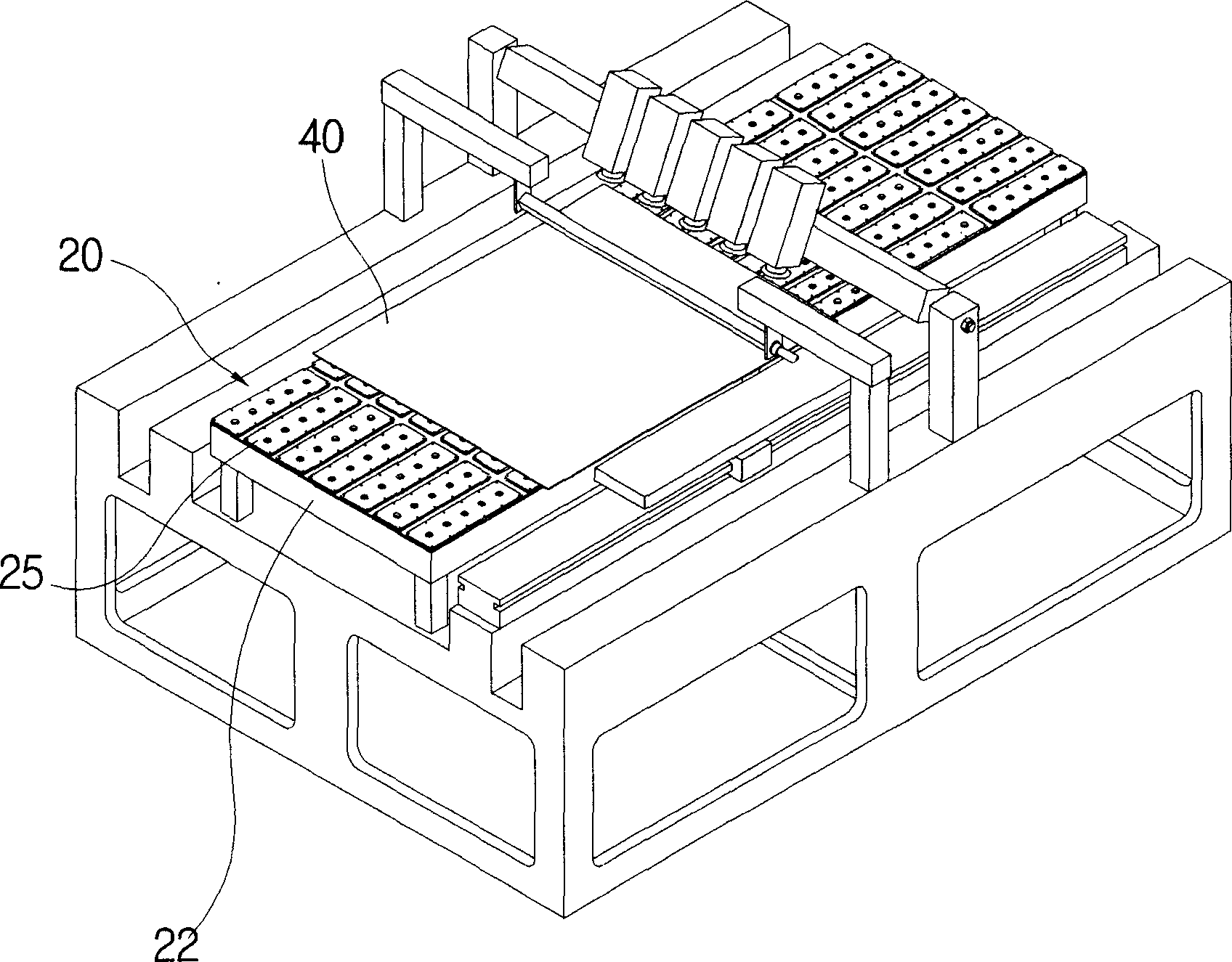

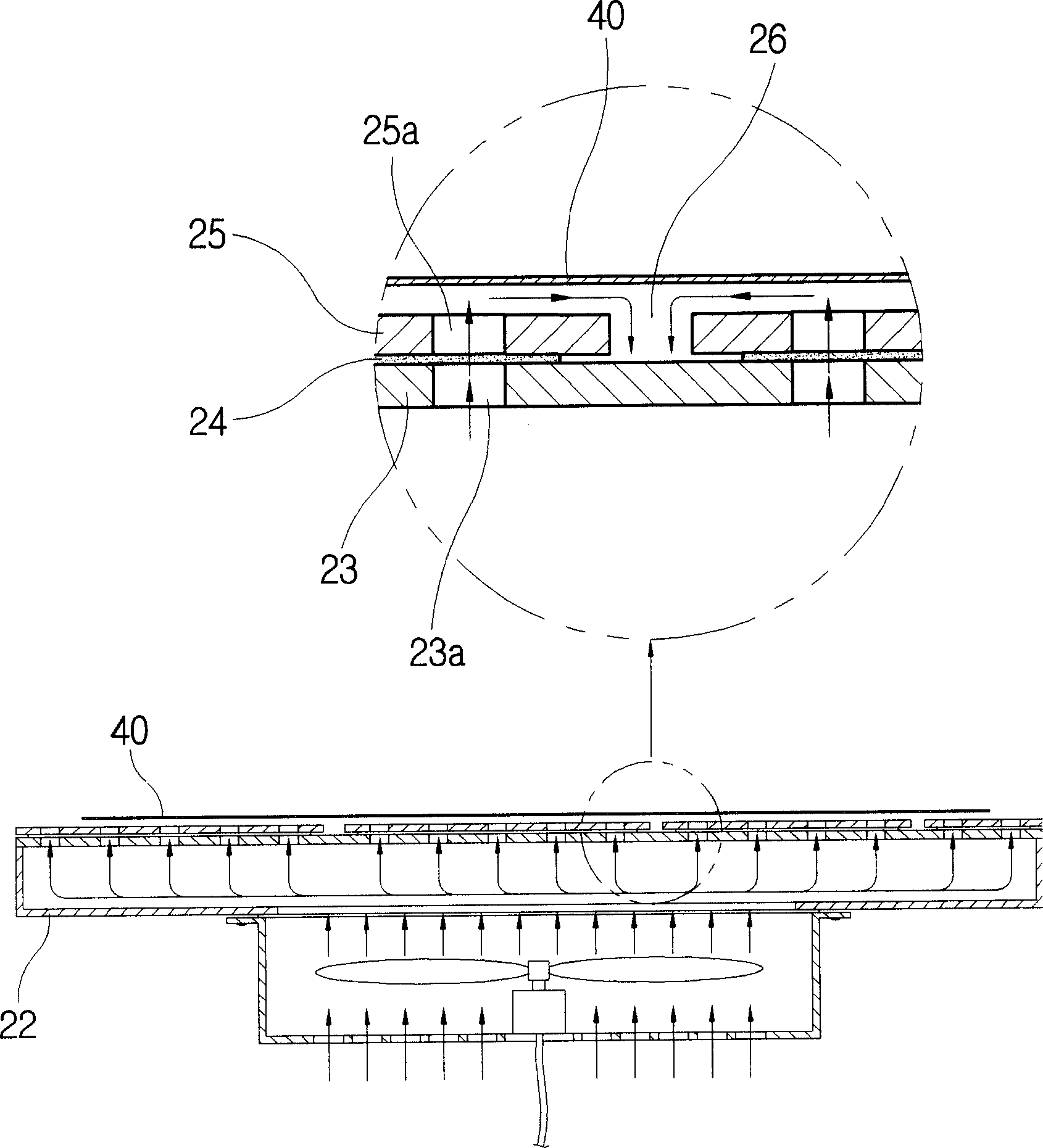

[0033] Such as Figure 3 to Figure 5 As shown, the flat glass conveying device of the present invention includes: a workbench 10 with an inspection part 11 arranged at the center of the upper part; conveying parts that are arranged on all positions of the above-mentioned workbench 10 from the front to the rear and are symmetrical to each other 20 . The conveyor 30 provided above the table 10 adjacent to one side of the above-mentioned conveying unit 20 .

[0034] The workbench 10 is in the shape of a bench-shaped square table, and above the upper surface of the workbench 10 at a certain height, an inspection unit 11 with a light source 11a and an imaging device 11b straddling the workbench is provided.

[0035] The above-mentioned transfer unit 20 is provided at a certain distance from the center of the workbench 10 to allow the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com