Automatic inspection method and device for polar electronic component in circuit board

An electronic component and automatic inspection technology, applied in electrical components, electrical components and other directions, can solve the problems of low detection efficiency, inability to realize automatic inspection, and small automatic inspection range, so as to improve detection efficiency, improve inspection efficiency and check Accuracy, improved traceability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

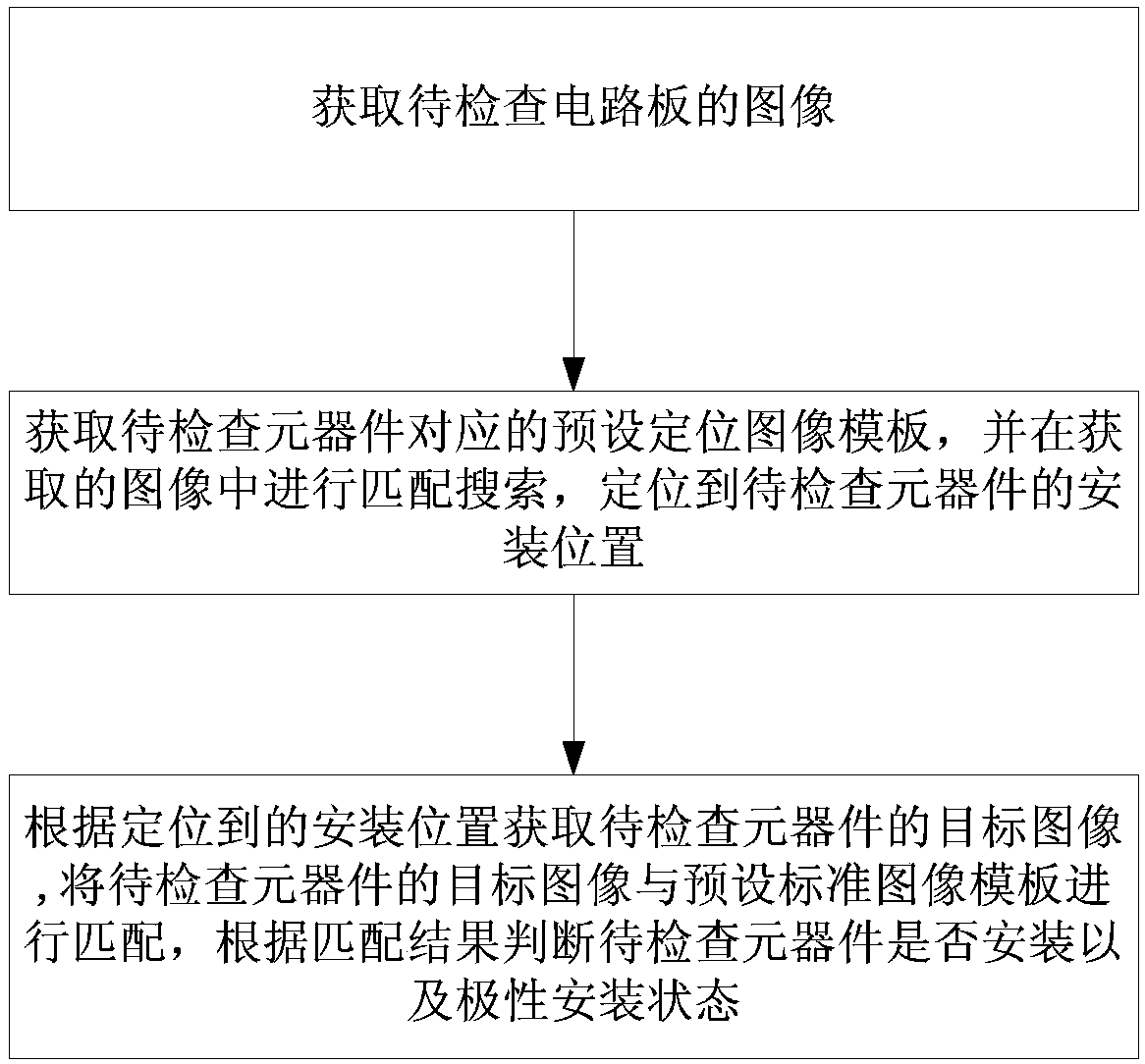

[0047] like figure 1 As shown, the automatic inspection method of polarized electronic components in the circuit board of this embodiment, the steps are:

[0048] S1. Image acquisition: acquire an image of the circuit board to be inspected.

[0049] This embodiment specifically uses a visual sensor to collect images of the circuit board to be inspected. The visual sensor can be composed of one or more graphic sensors, and is equipped with a light source and other auxiliary equipment. The visual sensor can specifically use a laser scanner, a line array or an area sensor. Array CCD cameras, TV cameras and digital cameras, etc.

[0050] In a specific embodiment, when the inspection is started, the circuit board to be inspected is placed in a closed inspection box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com