Thin-wall shell processing method

A technology of thin-walled shells and processing technology, which is applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc. It can solve problems such as inability to process, parts compacted and deformed, and affect the processing quality of parts, so as to achieve uniform pressing force Consistent, waste prevention, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

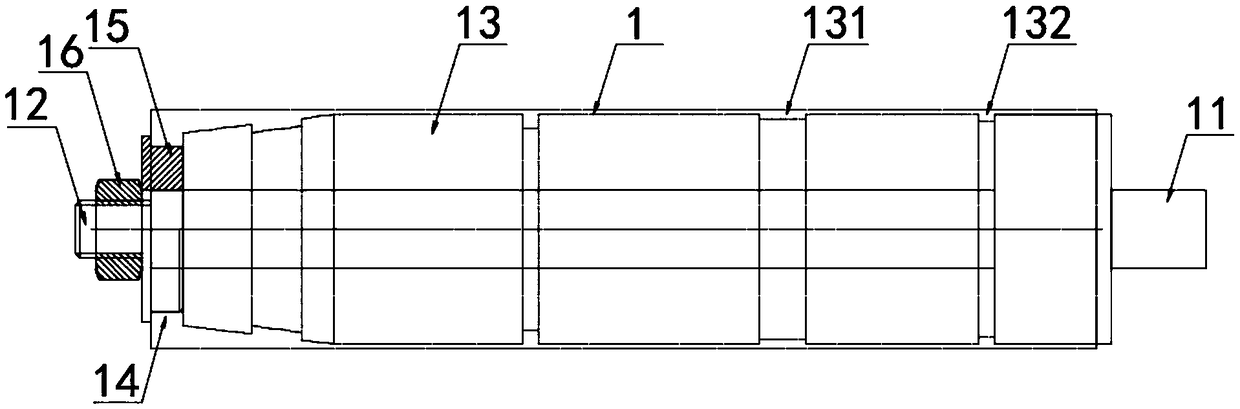

[0024] according to figure 1 A thin-walled shell processing method shown includes a tooling fixture 1, the tooling fixture 1 includes a mandrel 11, and one end of the mandrel 11 is provided with a mounting column 12, and the outer fixed sleeve of the mandrel 11 is provided with Outer ring body 13, a wide annular groove 131 and a thin annular groove 132 are provided on the outer ring body 13, a step 14 is provided between one end of the outer ring body 13 and the mandrel 11, and the outside of the step 14 is sleeved with Auxiliary pressure plate 15, the side of described auxiliary pressure plate 15 is provided with nut 16, and described nut 16 is threadedly connected with mounting column 12, and specific processing method is as follows:

[0025] Step 1: Rough turning of the outer wall, first rough turning the outer wall of the thin-walled shell, cutting off most of the machining allowance on the machined surface, and leaving an allowance of 3mm;

[0026] Step 2: Tempering at h...

Embodiment 2

[0034] according to figure 1 A thin-walled shell processing method shown includes a tooling fixture 1, the tooling fixture 1 includes a mandrel 11, and one end of the mandrel 11 is provided with a mounting column 12, and the outer fixed sleeve of the mandrel 11 is provided with Outer ring body 13, a wide annular groove 131 and a thin annular groove 132 are provided on the outer ring body 13, a step 14 is provided between one end of the outer ring body 13 and the mandrel 11, and the outside of the step 14 is sleeved with Auxiliary pressure plate 15, the side of described auxiliary pressure plate 15 is provided with nut 16, and described nut 16 is threadedly connected with mounting column 12, and specific processing method is as follows:

[0035] Step 1: Rough turning of the outer wall, first rough turning the outer wall of the thin-walled shell, cutting off most of the machining allowance on the machined surface, and leaving an allowance of 4mm;

[0036] Step 2: Tempering at h...

Embodiment 3

[0044] according to figure 1 A thin-walled shell processing method shown includes a tooling fixture 1, the tooling fixture 1 includes a mandrel 11, and one end of the mandrel 11 is provided with a mounting column 12, and the outer fixed sleeve of the mandrel 11 is provided with Outer ring body 13, a wide annular groove 131 and a thin annular groove 132 are provided on the outer ring body 13, a step 14 is provided between one end of the outer ring body 13 and the mandrel 11, and the outside of the step 14 is sleeved with Auxiliary pressure plate 15, the side of described auxiliary pressure plate 15 is provided with nut 16, and described nut 16 is threadedly connected with mounting column 12, and specific processing method is as follows:

[0045] Step 1: Rough turning of the outer wall, first rough turning the outer wall of the thin-walled shell, cutting off most of the machining allowance on the machined surface, and leaving an allowance of 5mm;

[0046] Step 2: Tempering at h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com