Road repairing device

A road repair and carriage technology, applied in the field of road repair, can solve the problems of cumbersome operation, time-consuming filling of new materials, and low strength of action, so as to save the cleaning operation and improve the efficiency of crushing or tamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

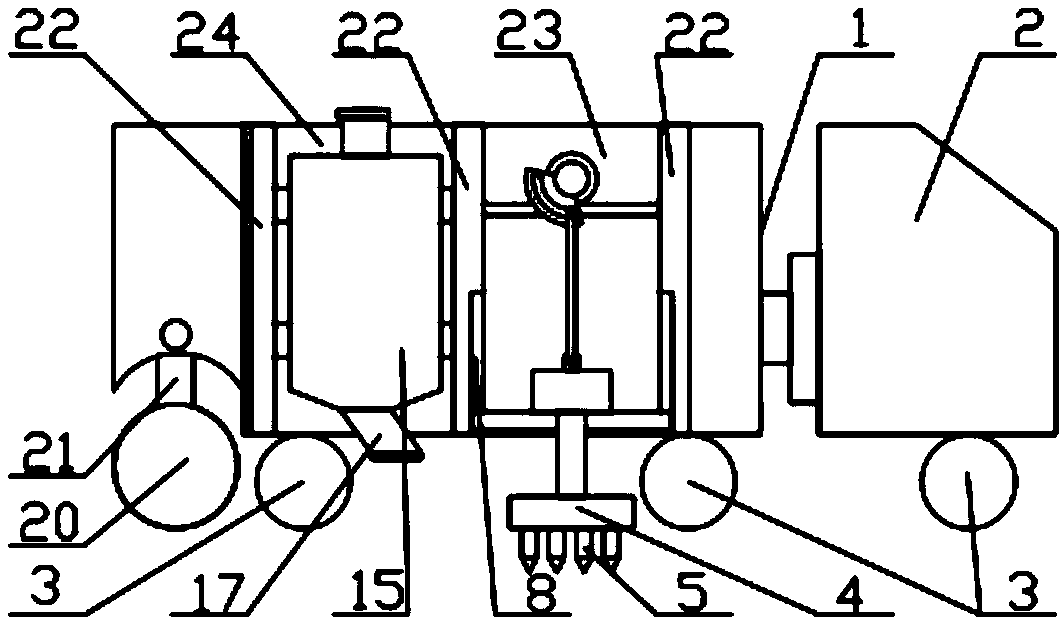

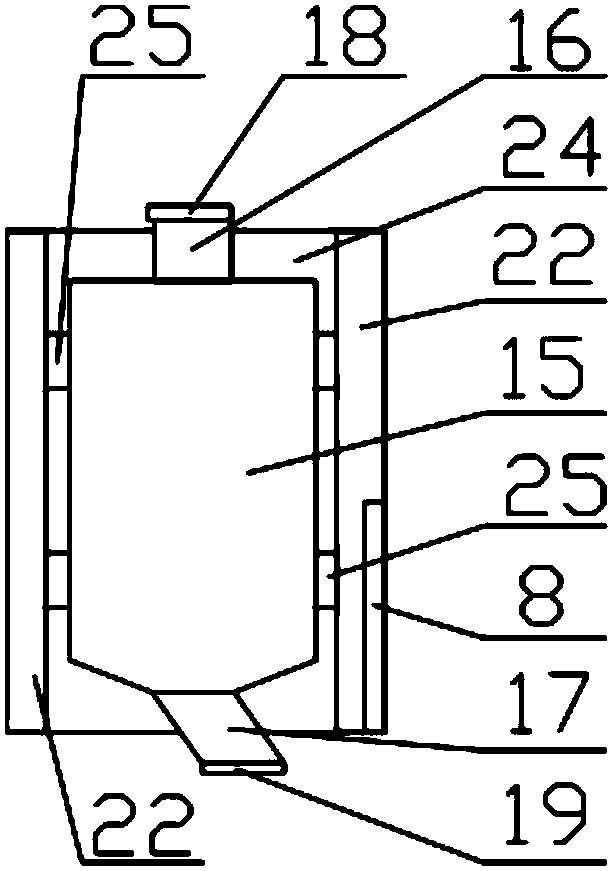

[0035] Such as figure 1 A road repairing device shown includes a car body and a crushing and tamping mechanism, an asphalt filling mechanism and a compacting roller 20 sequentially installed on the car body from the front end to the rear end of the car body advancing direction,

[0036] The vehicle body includes a compartment 1 and a headstock 2 connected to one end of the compartment 1, and wheels 3 are provided at the bottom of the compartment 1 and the front end;

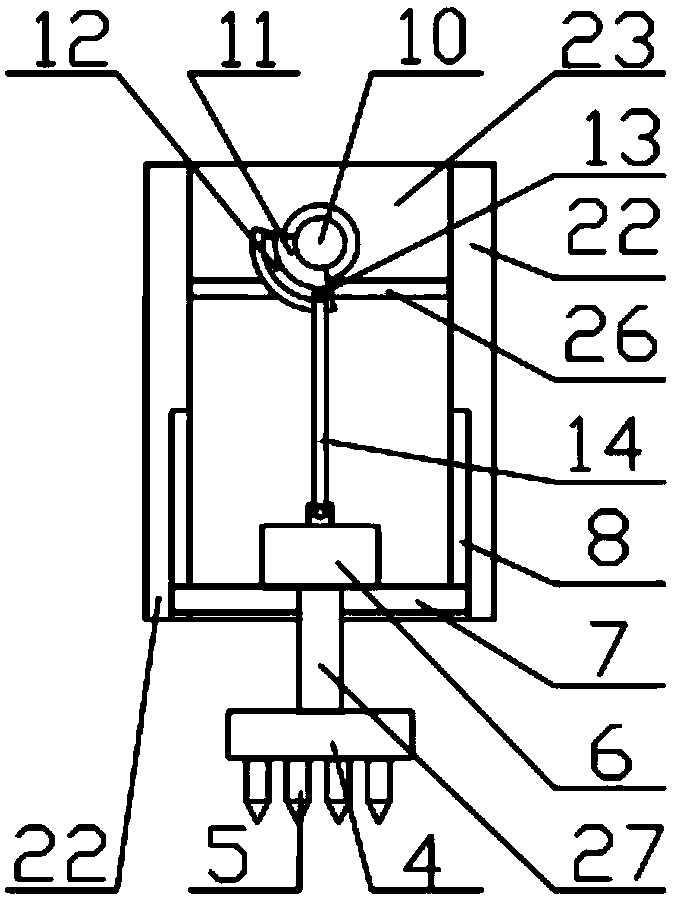

[0037] Such as figure 2 and Figure 4As shown, the crushing and flattening mechanism includes a flattened gravity disk 4 and several drill bits 5 evenly fixed on the lower surface of the flattened gravity disk 4, the lower surface of the flattened gravity disk 4 is a flat horizontal plane, and the flattened gravity disk The center of the upper surface of the disc 4 is provided with a connecting column 27 perpendicular to the tamping gravity disc 4, the upper end of the connecting column 27 is connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com