Waste organic glass crushing device

A plexiglass and crushing device technology, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of affecting production, long residence time, low crushing efficiency, etc., and achieve the goal of improving work efficiency, reducing crushing cost, and high-efficiency crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

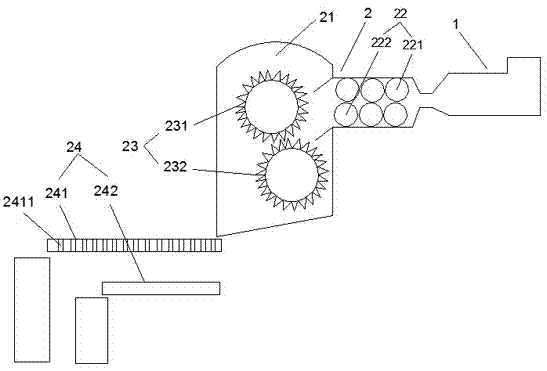

[0019] A crushing device for waste plexiglass, as attached figure 1 As shown, it includes a feed structure 1 and a crushing structure 2. The crushing structure 1 includes a crushing chamber 21, a crushing part 22 arranged in the crushing chamber 21 and a crushing part 23 arranged in the crushing chamber 21 behind the crushing part 22, A screening structure 24 is connected to the rear of the crushing part 23, including a first conveying plate 241 and a second conveying plate 242. The first conveying plate 241 is provided with a sieve hole 2411 with an aperture of 5-10 mm. Above, in this embodiment, the aperture diameter of the sieve is 8mm. Squeeze part 22 comprises upper squeeze roller 221 and the lower squeeze roller 222 opposite with upper squeeze roller 221; Crushing part 23 comprises the first crushing roller 231 and the second crushing roller 232 that arrange up and down, each crushing roller is provided with There are blades, and the blades on the first crushing roller ...

Embodiment 2

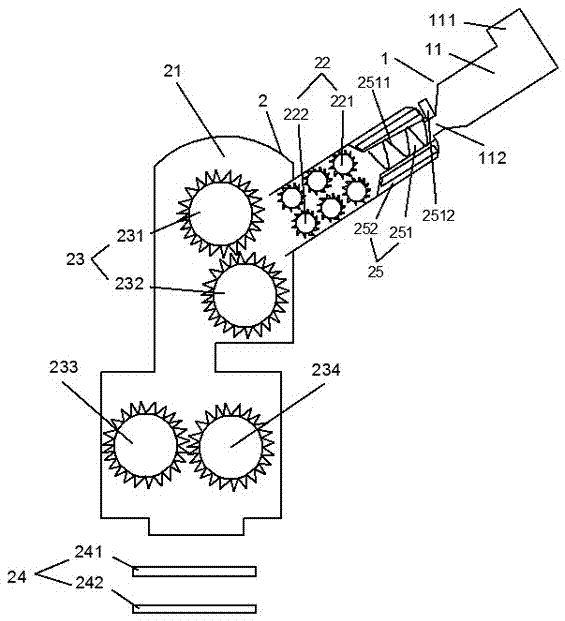

[0021] A crushing device for waste plexiglass, as attached figure 2 As shown, it includes a feed structure 1 and a crushing structure 2. The crushing structure 1 includes a crushing chamber 21, a crushing part 22 arranged in the crushing chamber 21 and a crushing part 23 arranged in the crushing chamber 21 behind the crushing part 22, The feeding structure 1 includes a feeding chamber 11 communicating with the crushing chamber 21 , and the feeding chamber 11 is provided with a feeding port 111 and a flat discharge port section 112 .

[0022] A screening structure 24 is connected to the rear of the crushing part 23, including a first conveying plate 241 and a second conveying plate 242. The first conveying plate 241 is provided with a sieve hole 2411 with an aperture of 5-10 mm. Above, in this embodiment, the aperture diameter of the sieve is 8mm. The extruding part 22 comprises an upper extruding roller 221 and a lower extruding roller 222 relative to the upper extruding rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com