Unloading and cleaning method for open wagon conveyed bulk materials after freezing and device thereof

A technology for bulk materials and post-unloading, which is applied in the field of unloading machines. It can solve the problems of easily damaged compartments, long time consumption, and large material particle size, and achieve good social benefits, high productivity, and fully enclosed and pollution-free material circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

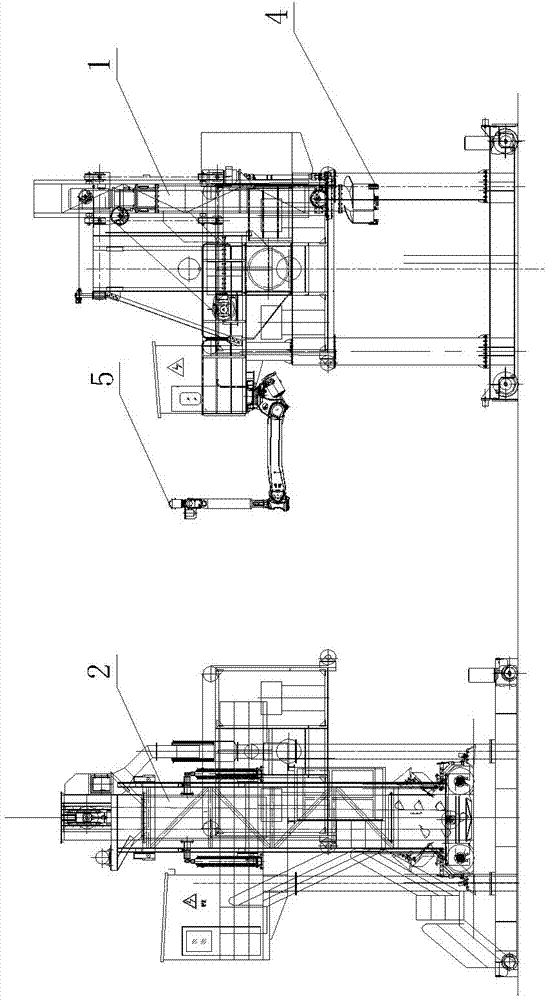

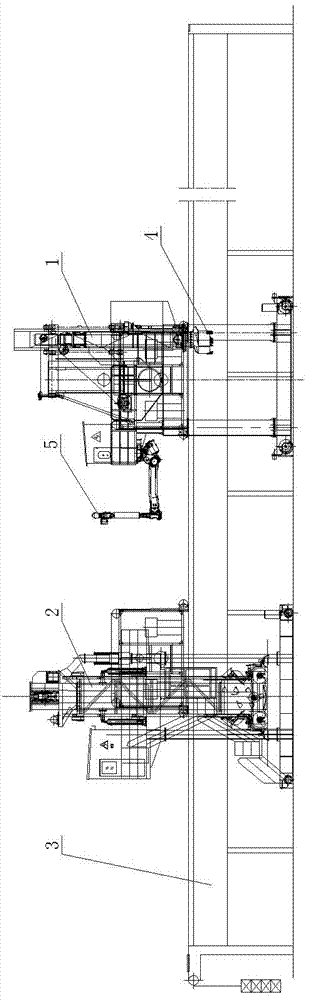

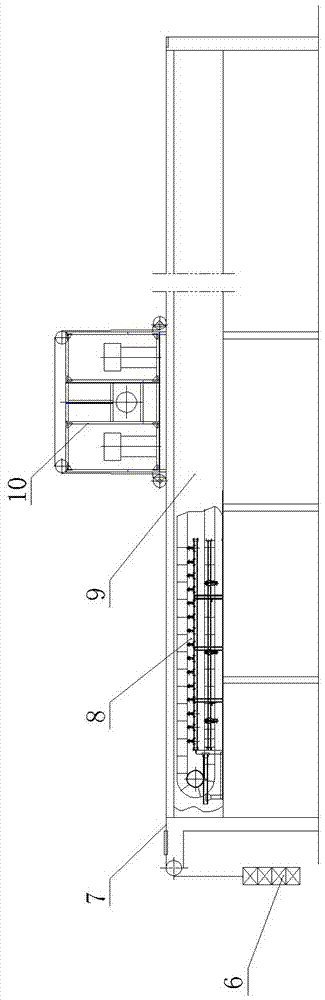

[0025] A method for unloading and clearing vehicles transported by gondolas after bulk materials are frozen, which consists of three processes: defreezing, unloading, and vehicle cleaning. The double vertical screw unloader running on the special track inserts the reclaiming head with the rotary deicing device vertically into the material in the compartment, and the rotary deicing device on the reclaiming head rotates and breaks the frozen material in the middle of the compartment. The double vertical auger unloader The two sets of boom-type deicing devices crush the frozen material on the side wall of the carriage, and the particle size of the material after crushing is less than 100mm; the unloading work is completed by the double vertical screw unloading machine, and the reclaiming head of the unloading machine takes the crushed material in the carriage. The material is collected and sent to the vertical screw conveyor. The material is sent into the sliding sealed bin throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com